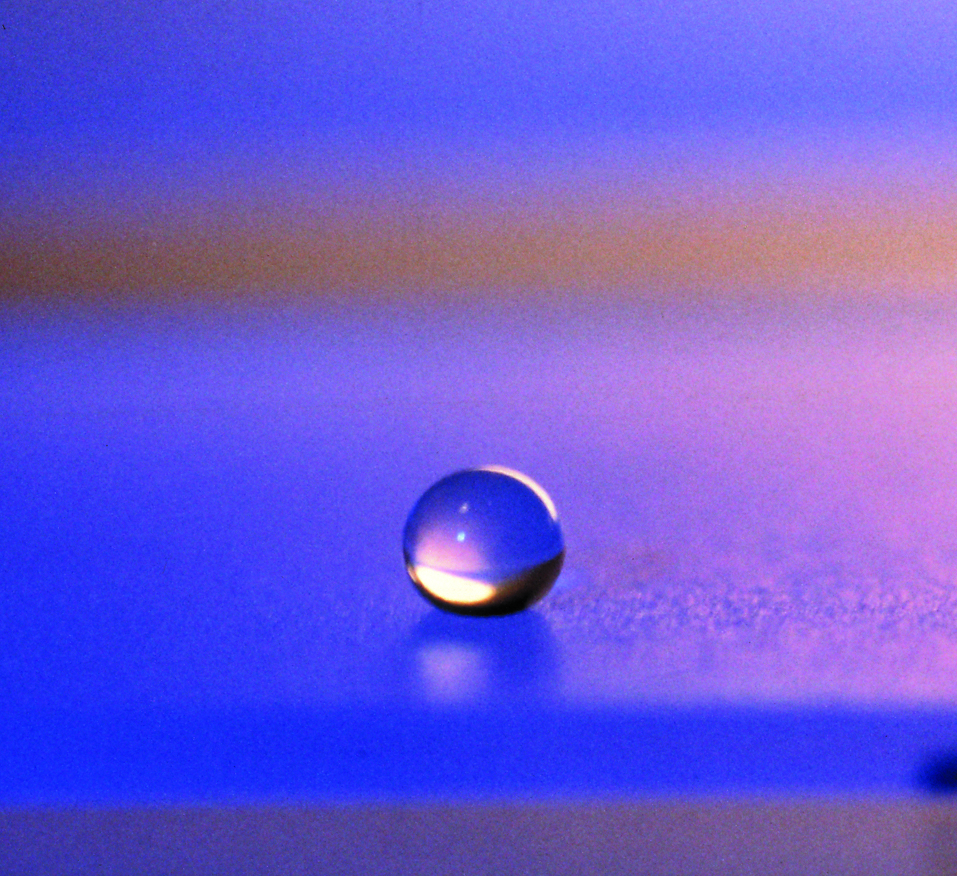

Non-stick coatings keep surfaces clean

Clean surfaces are essential in the processing industry. Plasma polymer easy-to-clean coatings offer ideal conditions for significantly reducing contamination on surfaces and facilitating their cleaning. In addition to their outstanding non-stick properties, the coatings are characterized by their low thickness, transparency and excellent adhesion to a wide range of substrate materials. Due to their chemical resistance, they also protect against corrosion and wear. The high temperature and hot steam resistance also allows their use in the field of hot steam sterilization. At Fraunhofer IFAM, various easy-to-clean coatings are being developed and brought to industrial application, e.g. for easy paint stripping or for food processing.

Environmentally friendly paint stripping from surfaces using PermaCLEANPLAS® coatings

Multi-layer paint deposits occur daily in paint lines. Cleaning by means of blasting and thermal paint stripping is usually labor- and cost-intensive. In addition, damage to surfaces and components can occur. To prevent this, Fraunhofer IFAM has developed the PermaCLEANPLAS® coating, which is used industrially on gratings and other operating equipment such as skid frames or door racks in painting lines. There, it enables permanent, easy and, above all, fast cleaning without disrupting the painting process. Cleaning can be carried out with high-pressure water without having to remove the grids. The coating thus not only makes a significant contribution to cost reduction, but also to savings in chemicals, energy and materials, since blasting processes or thermal paint stripping, which are otherwise often carried out off-site by specialist companies, can be dispensed with completely.

Developments have shown that, depending on the substrate, the coating can also be used in combination with other cleaning processes, such as CO2 snow blasting or soda blasting. This allows considerable cost and energy saving effects to be realized. With CO2 snow blasting in particular, mold surfaces can be cleaned directly on site (cleaning in place) and on demand.

Non-stick coatings for food processing: BestSKINPLAS®

Non-stick coatings are particularly in demand in the food industry. In addition to the high non-stick effect, food fastness, strong scratch and abrasion resistance, and high temperature resistance are particularly important. The BestSKINPLAS® coating from Fraunhofer IFAM has proven itself as a non-stick coating in various areas of food processing. Baking trays, baking pans, as well as embossing baking tools such as waffle irons, are successfully coated and used. In addition, it is also used as a repellent protective coating for filter elements, for example in milk and juice bottling plants. The BestSKINPLAS® coating is also suitable for CIP cleaning in the food and pharmaceutical industries. Coatings suitable for sterilization (e.g. for Sterilization in Place) can also be realized.

In contrast to PTFE-type coatings, for example, the BestSKINPLAS® coating is not used up during use. It is so well cross-linked that it is mechanically and chemically particularly stable and the processed foods are thus not unnecessarily contaminated.

Dirt-repellent surfaces through nanotechnology: NCTPLAS® coating

Even with layers just a few nanometers thick, surfaces can be excellently sealed. This enables good run-off behavior as well as easy and fast cleaning. The NCTPLAS® coating (Nano Coating Technology) developed at Fraunhofer IFAM has been used for many years for assemblies in dispensing and mixing technology for adhesives for film lamination. Due to its chemical resistance, coupled with its hydrophobic character, it enables a significant extension of the service life of these assemblies. In addition, the coating facilitates cleaning, for example with solvents.

The coating is particularly suitable for assemblies and components with the highest dimensional tolerance requirements because the coating process is cold, so the components remain at room temperature. In addition, the product surfaces do not have to be blasted before the coating process to ensure adhesion of the functional coating.

Researchers at Fraunhofer IFAM have been working for many years on the development of different easy-to-clean coatings. The comprehensive know-how of the team in the field of plasma technology and surfaces enables the coatings to be combined with further functions such as corrosion or wear protection. In this way, a wide variety of our customers' wishes can be realized. Many of the developed coatings are already successfully used in industrial applications.

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM