Drilling and milling with robots – high flexibility for precision requirements

A machining center with industrial robots from different manufacturers for milling and drilling is available for the R&D work. If desired, they can be used on a linear axis. The machining of lightweight structures up to a length of 13 meters can be undertaken.

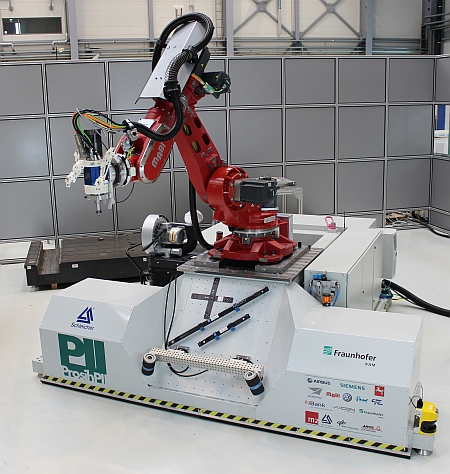

Mobile robots for machining

A linear axis extends the working space of machining robots in two directions, which is vital for effectively machining large components. Autonomous ground vehicles (AGVs) allow considerably greater freedom for positioning machining systems on the component. A prerequisite for good machining is, however, adequate static and dynamic stability of the vehicles. Within the framework of the ProsihP 2 project the automation team at Fraunhofer IFAM and industrial partners designed and constructed an autonomous mobile machining unit for interchangeable heavy-duty robots from any manufacturer. Using this system the developers successfully evaluated methods for the precise positioning and path guidance of end-effectors for adaptable production environments.

Water-jet cutting – abrasive water-jet cutting

Depending on material and process requirements, water-jet cutting can have advantages over conventional machining. In particular, thermal damage is avoided, there is constant cut quality due to the freedom from wear of the tool, and there is large variability regarding the wall thickness and mechanical properties of the component. Fraunhofer IFAM in Stade possesses a 6000 bar abrasive water-jet cutting plant with a 5-axis cutting head suitable for a range of applications.

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM