Next generation casting

From concept to product...

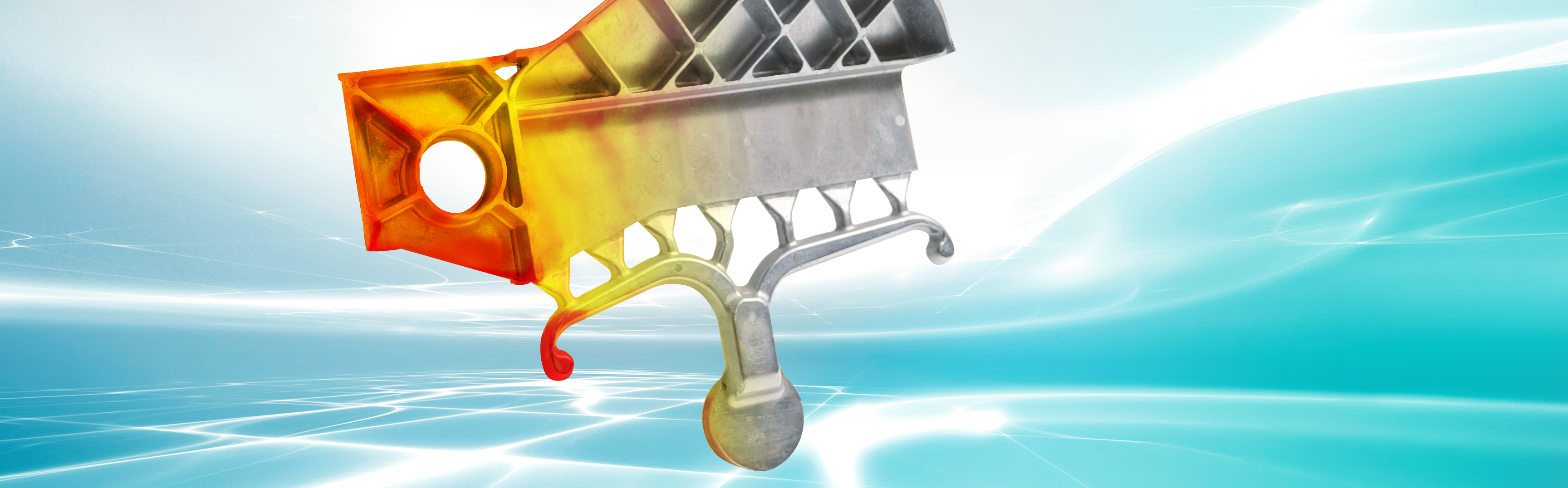

With its expertise in the field of casting technology, Fraunhofer IFAM supports industrial customers in the casting technology implementation of an idea from the concept to the first prototype to the applicable product. Different casting processes and materials are available suitable for the respective problem.

...all from a single source!

Our experts in the field of casting technology and lightweight construction are able to map the entire process chain from the concept phase to casting design, toolmaking, casting production and final metallographic or non-destructive testing.

Novel technology combinations

In addition to the classical casting technology issues, we also support our customers in cross-technology manufacturing and materials technology issues. To this end, project teams from different areas of Fraunhofer IFAM or other institutes of the Fraunhofer-Gesellschaft work together. Cross-cutting questions relating, for example, to corrosion, joining and adhesive bonding of castings, additive manufacturing, digitization, or artificial intelligence can be answered scientifically and application-oriented by an extensive network of employees. In this way, completely new combinations of technologies and material applications become possible.

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM