Rapid Solidification

Total view of melt spinning facility with periphery at Fraunhofer IFAM Dresden

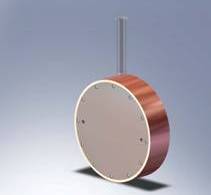

Flexible crucible system with small crucible and rotating cooling wheel

Flexible crucible system with big crucible and rotating cooling wheel

Process

In the melt spinning (MS) or planar flow casting (PFC) process a molten metal passes a nozzle and immediately touches the water cooled rotating Cu wheel. Ultrafine grained or amorphous material of metals and alloys can be manufactured by a rapid solidification (RS) device. Such ribbons or flakes have thicknesses of less than 100 µm.

Melt Spinner

- Cooling wheel - Cu alloy

- Ø 300 mm x 80 mm

- 3,000 min-1 - Inductive heating (40 kHz) - 2 crucibles

(10 – 20 cm³; up to 1,000 cm³)

- up to 1,700 °C - Atmosphere air, gas and vacuum in the recipient

- ribbon width up to 20 mm

Application potential (examples)

- Advanced alloys of aluminium and magnesium

- Catalizer materials

- Braze materials

- Thermoelectric materials

- Materials for hydrogen storage

Service offer

- Application-oriented development of rapidly solidified alloys

- Characterisation and analysis of material properties

- Utilisation of RS materials for demonstration and prototypes

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM