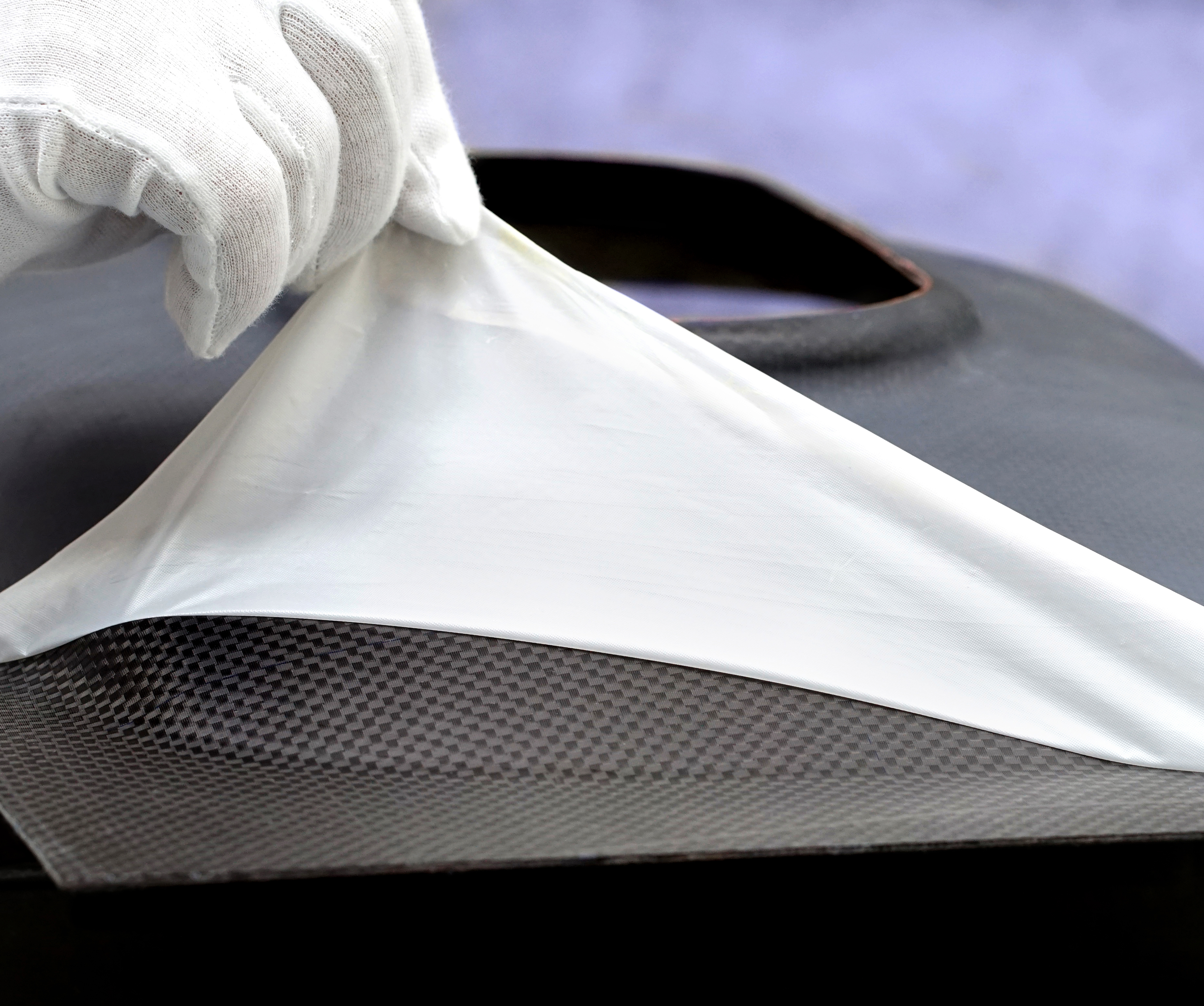

FlexPLAS® release film – release agent free manufacture of FRP components in complex hot press molds

At the JEC 2018 fair in Paris (6-8 March) the Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM will present for the first time the use of flexible FlexPLAS® release film in complex hot press molds. You are invited to visit us on the communal stand of CFK Valley in Hall 5 A, Stand E 58.

The plasma-coated FlexPLAS® release film developed by Fraunhofer IFAM (Bremen and Stade) has already been successfully used for a number of years for the manufacture of contaminant-free fiber reinforced plastic (FRP) components. In collaboration with Infiana Germany GmbH & Co. KG this technology is now being adapted and further developed for special customer requirements. It is used to replace conventional release agents and allows components to be removed from molds without any residuals. Additionally, the mechanical separation of the component from the mold via the film means the molds have a considerably longer service life. FlexPLAS® release film is a worldwide first, namely it is the only flexible plasma-polymer coated release film that allows the manufacture of contaminant-free FRP components.

The Automation and Production Technology team at Fraunhofer IFAM's Research Center CFRP NORTH (Forschungszentrum CFK NORD) in Stade have recently successfully extended the potential use of FlexPLAS® release film: The production of carbon fiber reinforced plastic (CFRP) using prepregs in a hot press enables the production of large batch numbers with two smooth sides in short cycle times. Also, high and constant component quality is guaranteed and no time-consuming sanding of components after curing is required. There is furthermore no need to clean or apply release agent to the molds, so increasing the added value. The research work has demonstrated that FlexPLAS® release film can also be used for molds of more complex geometry by adapting the process steps and parameters for prepregs in hot presses. The film provides protection for the cured component and can be easily removed, so leaving a clean matt surface that can be coated/lacquered without further pre-treatment.

The next development steps are explained by Joachim Scheller, Project Leader for Adaptive Application Systems: "We will start by implementing an already planned automation concept for release agent free FRP manufacture in complex press-molds. As a result, we will increase the degree of automation of the film feed, the inserting of the preform, and the component removal and so further increase the benefit of using FlexPLAS® release film for the hot pressing of prepregs."

The Automation and Production Technology team at Fraunhofer IFAM not only utilize their technical expertise in this area but also their knowledge of FRP manufacture. This combined know-how allows us to develop tailored technologies and processes with FlexPLAS® release film to meet customer requirements.

Further information – Fraunhofer IFAM I

Automation and Production Technology

www.ifam.fraunhofer.de/en/Profile/Locations/Stade

Press contact

Anne-Grete Becker – anne-grete.becker@ifam.fraunhofer.de

Further information – Infiana Germany GmbH & Co. KG

www.infiana.com

Press contact

Peter Kuhmann – peter.kuhmann@infiana.com

Photo

© Fraunhofer IFAM, but can be published in reports about this press release.

Download via: http://www.ifam.fraunhofer.de/de/Presse/Downloads.html

Last modified:

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM