Generating electrical energy from waste heat: Fraunhofer researchers develop innovative test rig for testing thermoelectric modules

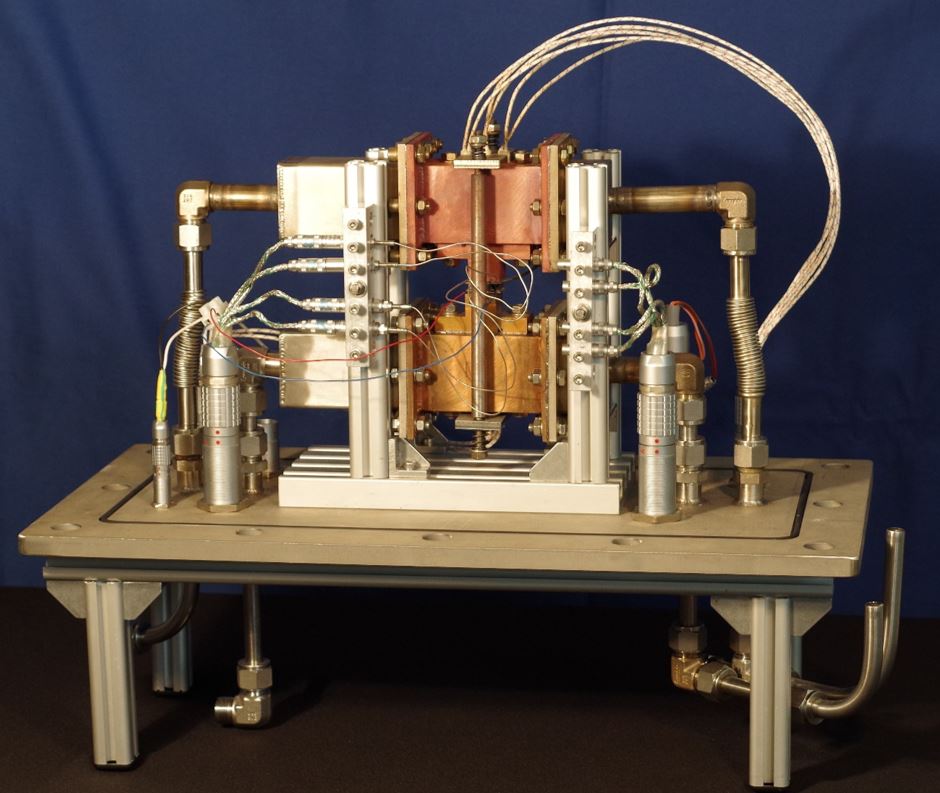

Scientists at the Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM in Dresden have succeeded in developing a novel test rig for the dynamic characterization of thermoelectric modules.

The direct conversion of heat into electrical energy has been the focus of science for some time. For example, in order to make sensible use of waste heat in industry and improve energy efficiency, specific thermoelectric modules are needed for the direct conversion of heat into electricity. When developing the modules, it is necessary to characterize them under conditions that are close to the application, such as thermal cycling. This has posed particular challenges on research to date.

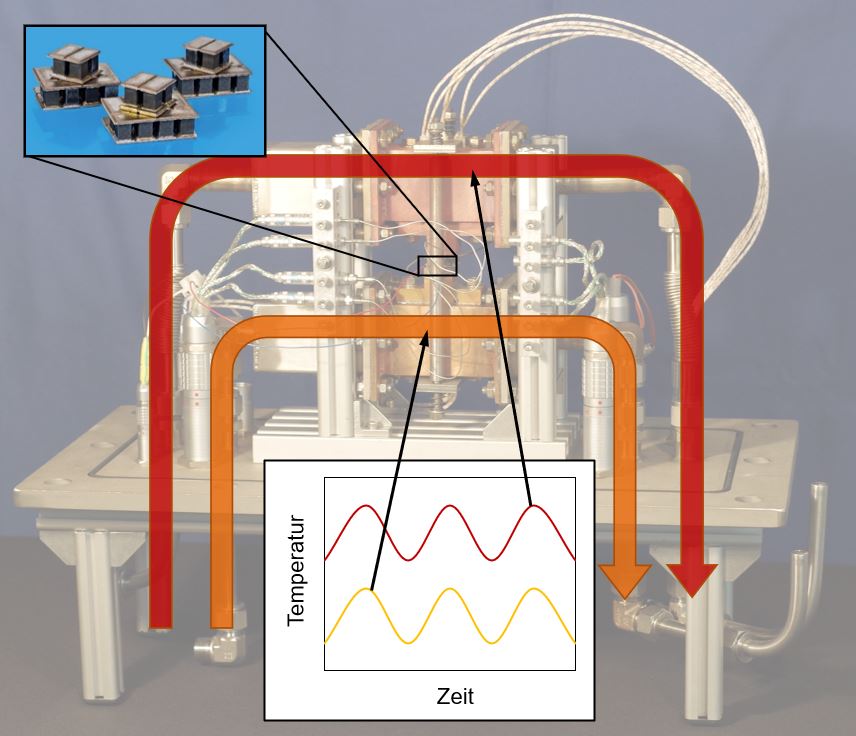

In contrast to previous models, the newly developed dynamic test rig operates under near-application conditions at temperatures of up to 600 °C. It has a hot and a cold side which can be controlled and cycled independently of each other in terms of temperature level. This allows cyclic temperature changes to be simulated as they occur in practice. Thus, the new test rig is a decisive addition to the model previously available at Fraunhofer IFAM, with which the researchers have so far only been able to carry out investigations under steady-state conditions.

The innovative test rig enables Fraunhofer IFAM scientists to determine the efficiency and the generated electrical energy of the modules under specified conditions. In addition, the thermal shock resistance of the material can be tested from a material perspective. Different atmospheres, such as inert gas or vacuum, can also be used in the test.

A thermoelectric module of a size of up to 50 x 50 mm² can be arranged between the hot and cold sides of the new test rig. The hot and cold sides are controlled by means of electrical heating in combination with air or gas cooling.

The new thermoelectric test rig is just one example of the ongoing test rig development in the business unit Energy and Thermal Management at Fraunhofer IFAM Dresden. The development of the concept as well as the design, construction, assembly, and commissioning were carried out in-house.

The researchers at Fraunhofer IFAM Dresden have extensive expertise in heat transfer, fluid mechanics, and design. Their experience comes from a large number of projects in the field of energy technology. In the past, it has generally been possible to develop appropriate test rigs for research in a wide range of topics. For example, a trainer for characterizing heat transfer during evaporation and a trainer for determining thermal conductivity at room and high temperatures for material mixtures were developed. Pressure loss channels and a cycling test rig for material tests in PCM (Phase Change Materials) are further concise examples.

During development, the scientists use the possibilities for design and mathematical modeling with the aid of commercial software, such as COMSOL Multiphysics. Fraunhofer IFAM Dresden also has the appropriate infrastructure for determining necessary thermal material parameters, such as thermal conductivity or thermal capacity. The new thermal engineering laboratory is equipped with the latest measuring techniques for carrying out experiments to determine, for example, the temperature, pressure, or flow rate of a wide range of materials, or to condition gas and liquid flows.

Further information on the business unit Energy and Thermal Management at Fraunhofer IFAM Dresden.

Last modified:

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM