Motek l Bondexpo l Efficient large-structure assembly: outsourcing & automation of adhesive tolerance compensation process

Agile production technologies from Fraunhofer IFAM in Stade – Automated rudder hinge assembly in aircraft vertical tail planes

Motek 2022 l Hall 7 l Booth 7115 l The Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM in Stade, Germany, will present automation solutions on a 1:1 scale for the first time at the International Trade Fair for Automation in Production and Assembly from October 4 to 7 in Stuttgart, Germany.

High-precision machining, joining and assembly of large structures focus on new weight-saving materials as well as manufacturing processes that not only increase efficiency and decrease costs in production, but also reduce energy consumption in operation, which in turn saves costs and supports climate protection.

The compatibility of efficiency, sustainability, and ergonomic workplace design is currently one of the greatest challenges in large-scale structure assembly, which is particularly relevant in aircraft, rail vehicle, ship, commercial vehicle, and wind energy plant construction. The experts for Automation and Production Technology from the CFK NORD Research Center in Stade, Germany, are addressing this issue and providing insights into current application-oriented R&D results in the context of automated assembly, including machining and joining processes.

Optimized production of aircraft vertical tail planes

The high-precision positioning of components plays a very important role in aircraft construction – as well as in other industries. Among other things, this is made possible by modern measuring and referencing methods, highly precise positioning technologies, and, last but not least, continuous digital process control. Fraunhofer IFAM will demonstrate this in an exemplary manner at Motek 2022:

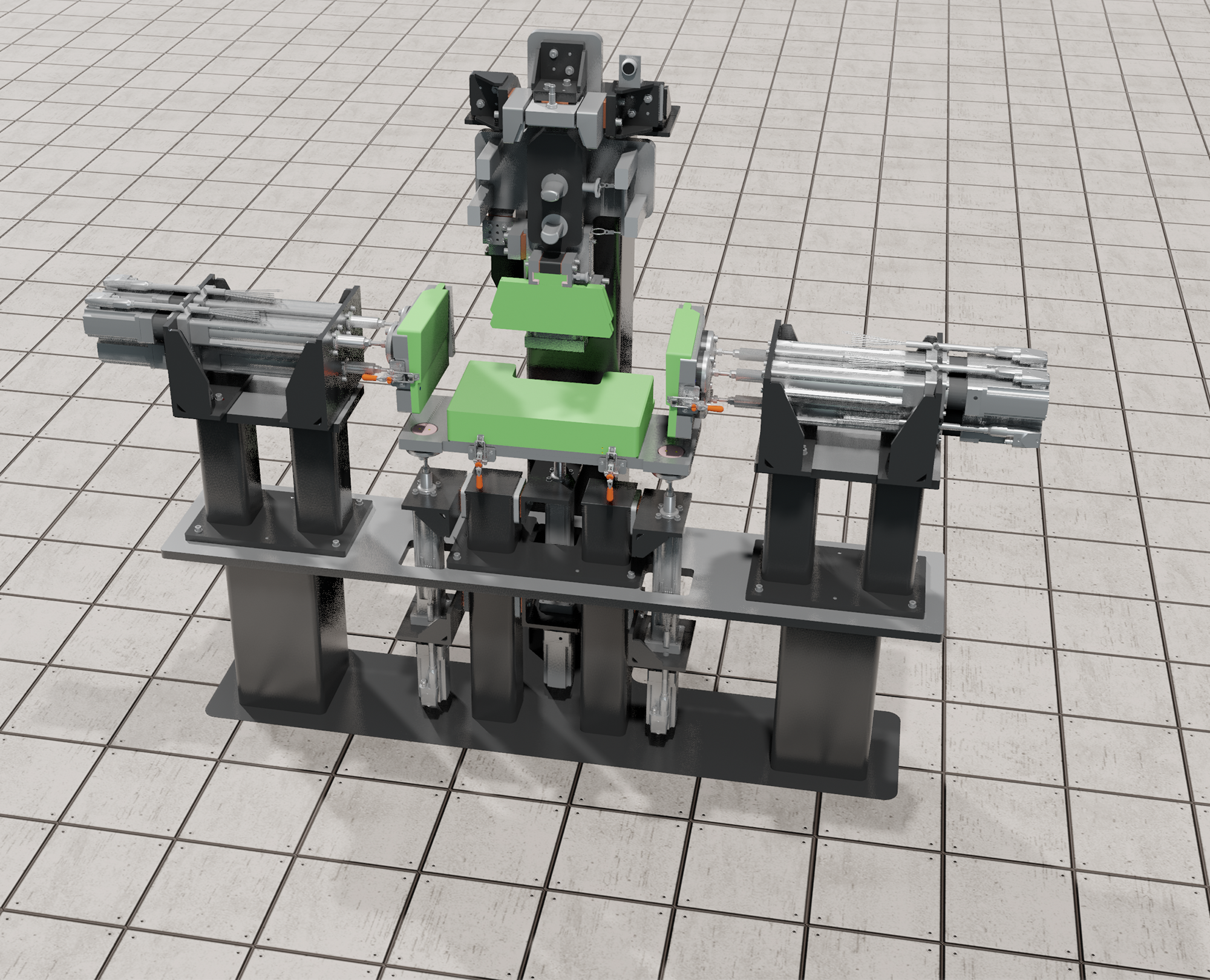

As a result of the joint project "Fast-FlexMont2" ("Research on Agile Production Technologies for CFRP Box Structures") funded by the German Federal Ministry of Economics and Climate Protection, the focus of the trade show presentation is on a dynamic demonstrator that makes it possible to optimize the production processes of aircraft vertical tail planes (Figure 1; video).

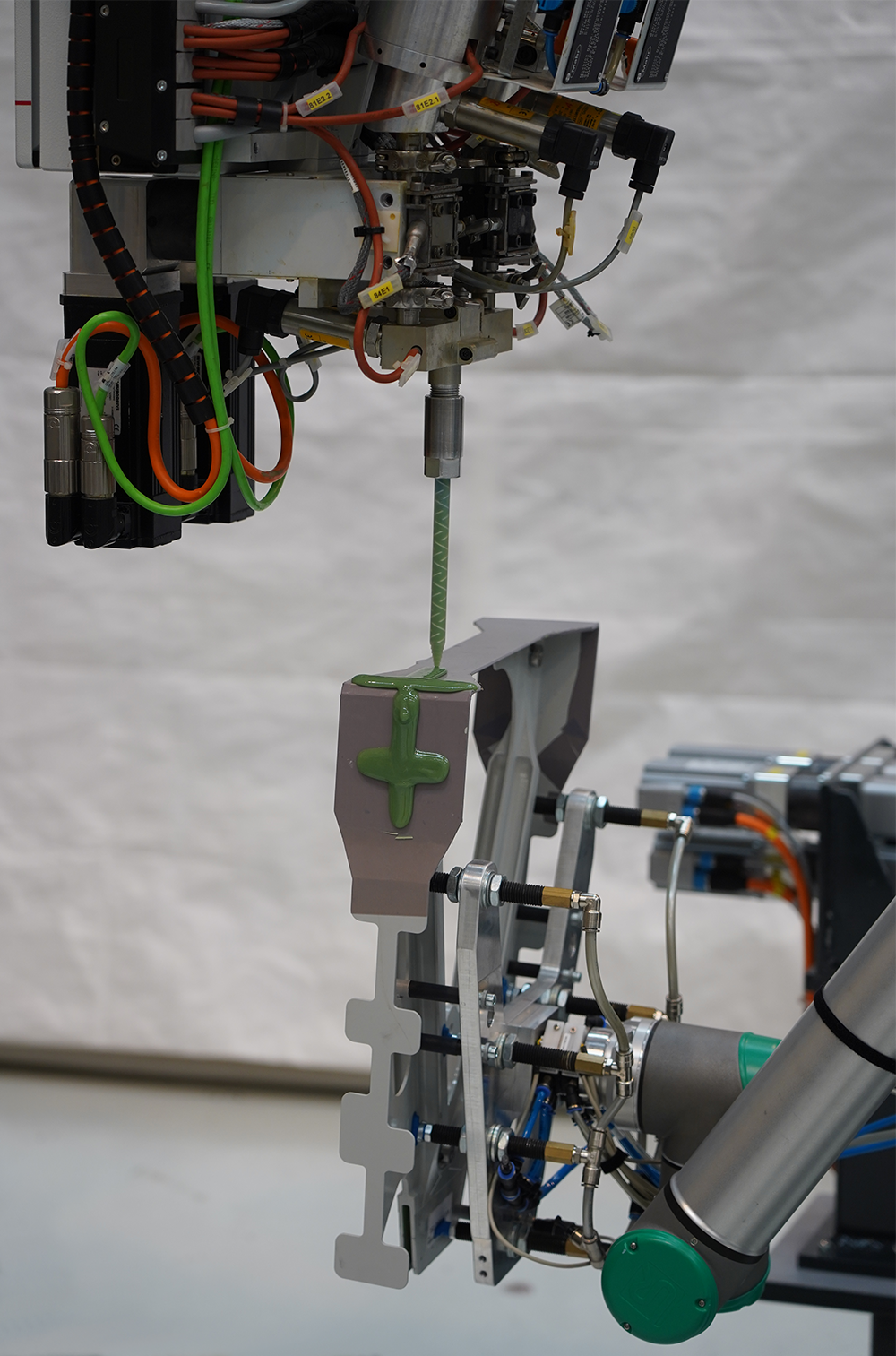

With the aim of no longer interrupting the assembly of rudder hinges to the vertical tail plane box by long waiting times, researchers at Fraunhofer IFAM – in cooperation with Airbus Operations GmbH and FFT Produktionssysteme GmbH – developed the application (Figure 2) and outsourced curing of shim material (gap-filling material) as parallel processes. In this context, automated and digitally linked processes allow volume-accurate dispensing and application as well as precise shaping and edge finishing of the liquid shim. After curing of the gap-filling material, the finished shimmed rudder hinge is inserted into the vertical tail plane.

Supported by digitization, automated process technologies not only enable the application of shim material based on component variants and according to requirements, but also the outsourcing of the curing process in preparation for the assembly of components in the aircraft vertical stabilizer box, using the rudder hinges as an example. Lightweight robotics-based assembly assistance systems are used to facilitate manual manufacturing processes while ensuring consistent quality.

In addition to agile manufacturing, this optimization also achieves the reusability of technical resources through the parallelization of work steps, thus increasing productivity while reducing costs.

Perspectives

Based on the results of the "Fast-FlexMont2" project, further manufacturing steps and their design with digitalized and automated sub-processes are being identified for optimization along the process chain, independent of individual branches. For example, the integration of digital marketplace structures for cross-company manufacturing is conceivable. Research will focus not only on individual production activities, but also on considerably more complex component geometries.

More information

Trade fair

- Find out more – visit us from October 4 to 7, 2022 at Motek in Stuttgart, Hall 7 l Booth 7115.

- https://www.ifam.fraunhofer.de/en/Events/motek-2022.html

Video

Automated Rudder Hinge Assembly in Aircraft Vertical Tail Planes (VTP) by Fraunhofer IFAM in Stade

Publication

Reichel, Björn; Diehl, Benjamin: »Teilprozesse sinnvoll auslagern – Effizienzsteigerung im Flugzeugbau durch Auslagerung und Automatisierung des klebtechnischen Toleranzausgleichs« in Berger, Karl-Friedrich; Kiefer, Sandra (Hrsg.): »JAHRBUCH Dichten.Kleben.Polymer.2023«. Mannheim, ISGATEC GmbH, 2022, S. 346-355

Website

www.ifam.fraunhofer.de/en/stade

Flyer

Photos

© Fraunhofer IFAM, but can be published in reports about this press release.

Photos and PDF for Download

Last modified:

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM