Plasma coatings from Fraunhofer IFAM - chemical-free, functional, REACH-compliant

The demand for special functional coatings for products and semi-finished products is very high in many industrial sectors - from automotive production and plastics processing to medical technology or biotechnology. Fraunhofer IFAM is researching and developing plasma-assisted coating processes which decisively improve the range of properties of these (semi-finished) products almost independently of the material used. And without the use of chemicals! This makes these processes particularly interesting at present, because it helps companies to comply with regulations such as the REACH regulation or the HSE guidelines.

The three advantages of plasma coatings: thin, chemical-free and material-independent

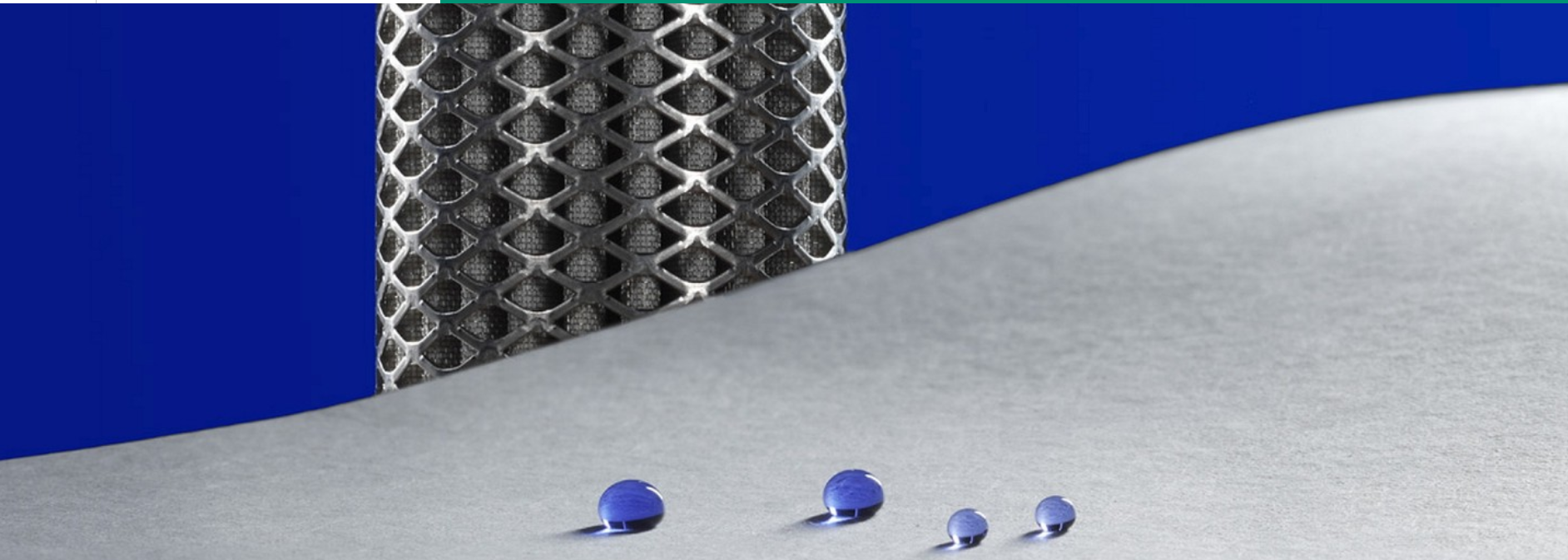

Plasma coatings enhance the properties of many products and semi-finished products: targeted plasma treatment provides their surfaces with a variety of functions such as adhesion promotion, corrosion protection or aging protection. Depending on the function, plasma coatings offer different advantages. However, all plasma coatings have three major advantages in common.

- Extremely thin: plasma technology can be used to produce thin layers with a thickness typically between 10 nanometers and 1 micrometer. The component geometry therefore remains virtually unchanged.

- Chemical-free: the plasma layers are produced in a dry chemical process. The use of wet chemical substances such as primers or release agents can therefore be dispensed with.

- Virtually independent of materials: whether metals, polymer plastics or fiber composites - plasma-supported coating processes can be used on almost all materials.

Plasma: the environmentally friendly alternative for many industries

Plasma coating processes provide an economical and environmentally friendly alternative to wet chemical treatment processes for many different industrial manufacturing processes. Table 1 shows a selection of possible applications.

If wet chemical coating processes are to be dispensed with due to employee and environmental protection (REACH, HSE), industry-specific regulations or cost savings, it is worth considering the use of plasma technology. The researchers at Fraunhofer IFAM provide advice on this and, if necessary, carry out feasibility studies.

Industries |

Selection of possible functional coatings |

| Automotive and aircraft construction |

|

| Energy sector |

|

| Medical technology |

|

| Maritime technologies |

|

| Plant and mechanical engineering |

Particularly interesting for food production and processing, where flaking of protective coatings must be avoided at all costs. |

Functional layers for different applications

Different functional layers can be produced by means of plasma coating. The table shows a selection of functions and benefits which the experts at Fraunhofer IFAM have often realized for customers from different industries and in publicly funded projects.

It should be emphasized that these functions can often be combined. For example, plasma coatings can be produced for electronic components, which combine electrical insulation, corrosion protection, and aging protection. In medical technology, it is possible to produce implant coatings that are antibacterial and at the same time can store antibiotics that promote acceptance of the implant by the body.

Function |

Advantages (selection) |

Possible applications |

| Adhesion promotion |

|

|

| Release coating | Release agent-reduced or even release agent-free demolding of molded parts | Can be implemented for various plastic and FRP processing methods, including:

Get to know the ReleasePLAS® release coating system developed by Fraunhofer IFAM! |

| Easy-to-Clean |

|

Fraunhofer IFAM has developed Easy-to-Clean coating systems for various applications, including:

|

| Corrosion protection |

|

|

| Protection against aging and insulation |

|

Especially in electronics:

|

| Friction reduction and abrasion protection |

|

|

| Antibacterial |

|

|

| Storage |

|

Particularly interesting for medical technology: antibiotic-containing coatings with adjustable release behavior |

Plasma coating process supplemented by laser technology

Both plasma-enhanced chemical vapor deposition (PECVD) and physical vapor deposition (PVD) can be used to create new application-specific surface properties without significantly changing the geometry of the component. In combination with laser treatments, be it structuring or smoothing, these properties can be optimized in many ways, for example in adhesion (bonding), tribology, or wetting (superhydrophilicity, superhydrophobicity). Fraunhofer IFAM has the corresponding know-how in laser technology.

Dr. Jörg Ihde is head of the department "Plasma Technology and Surfaces" at Fraunhofer IFAM. With his team of researchers, he offers extensive knowledge of all aspects of the use of plasma, laser, and VUV technologies in surface engineering. In close cooperation with customers from industry, they develop customized plasma coatings. Many of them are already successfully implemented in manufacturing in a wide range of industries.

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM