Ray tracing for optimized surface treatment with light

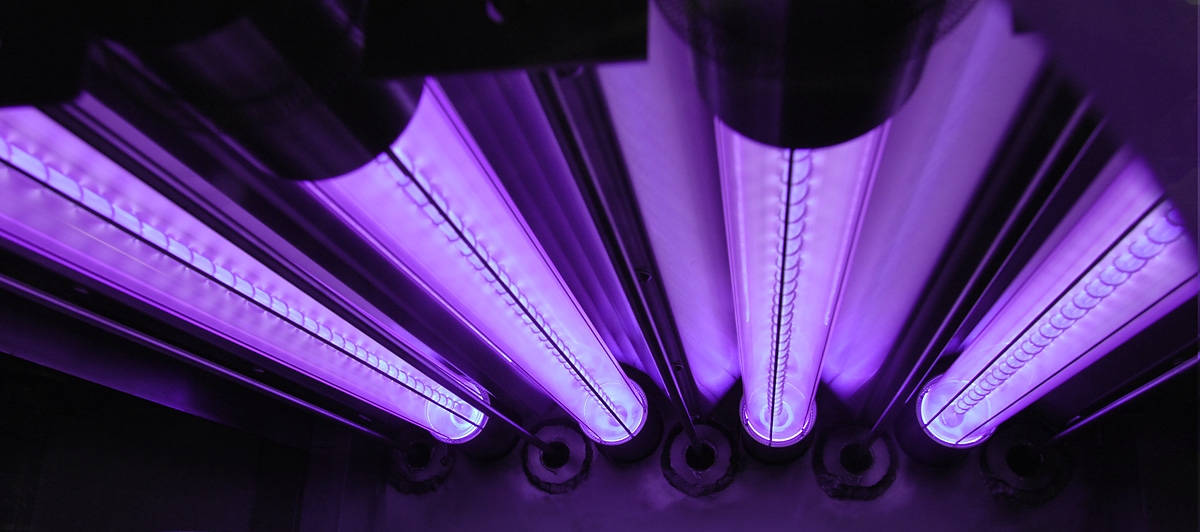

The irradiation of surfaces with light is a common procedure in surface technology. It can be used, for example, to clean or activate surfaces before the adhesive bonding or coating process. Currently, there is also great interest in the disinfection of surfaces with UV light. In order to design and optimally configure irradiation systems, researchers at Fraunhofer IFAM simulate light distribution and intensity with an algorithm that has recently gained publicity for its application in 3D computer graphics: ray tracing.

Simulating light in a computer-aided model

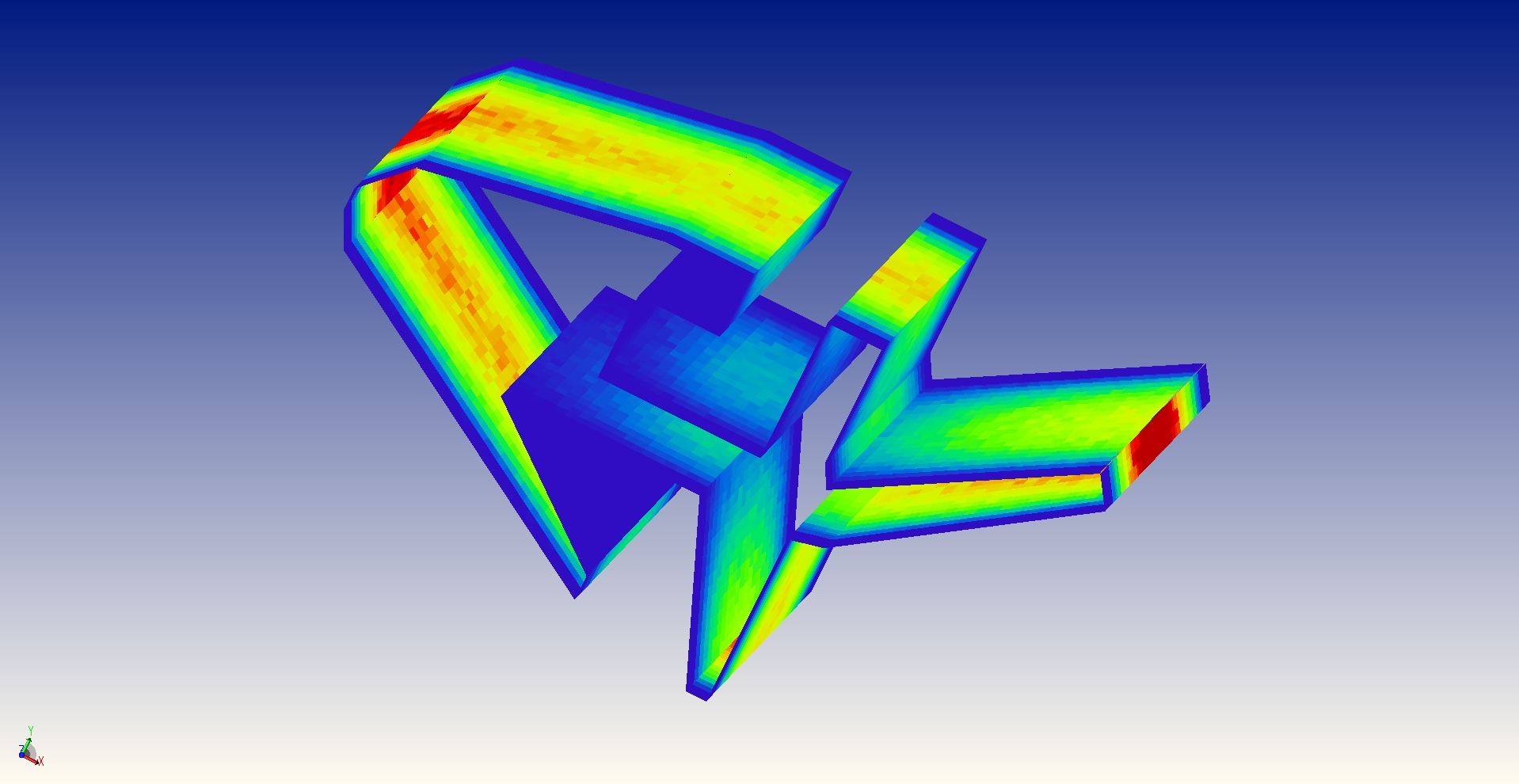

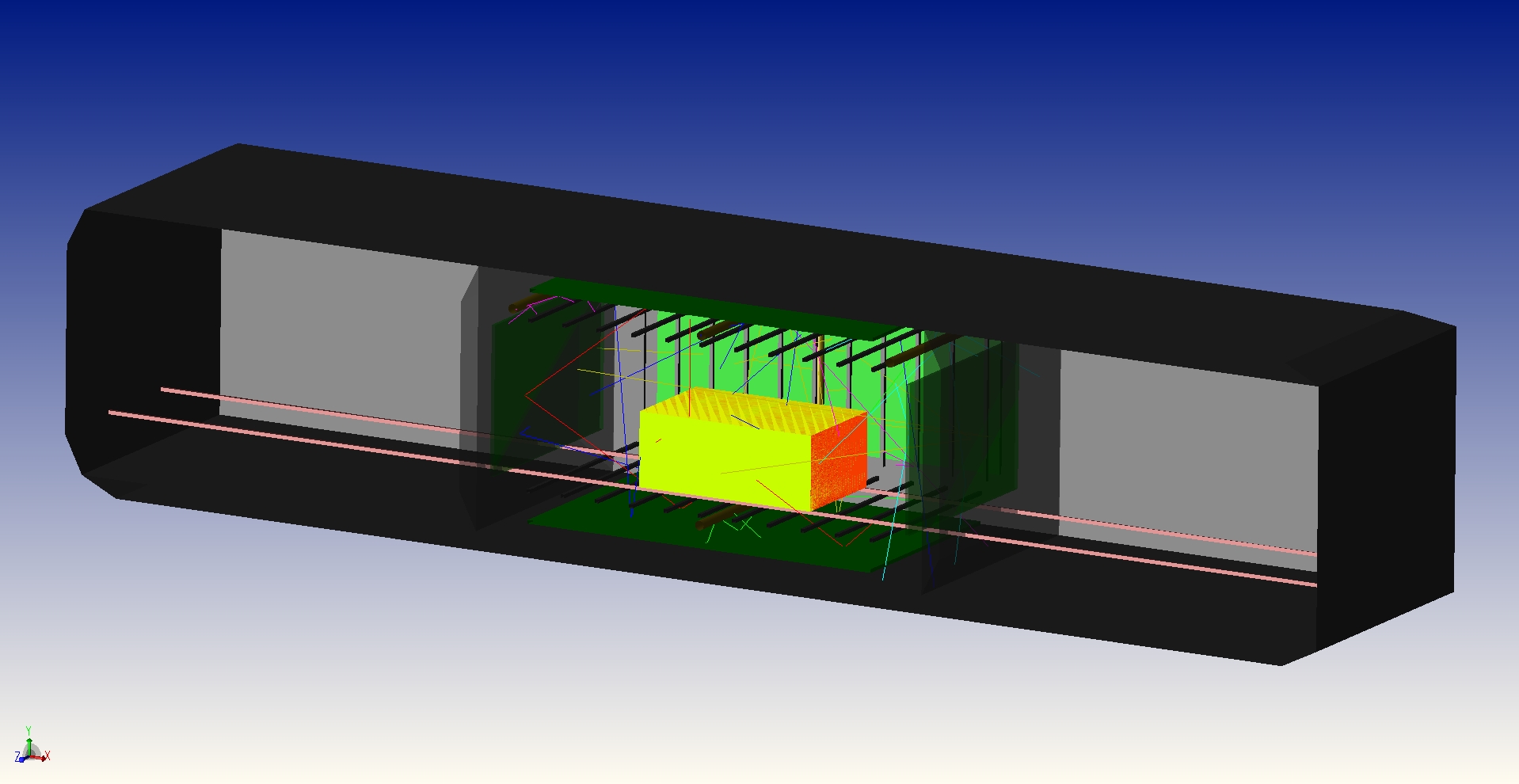

Ray tracing is not only about imaging the illuminated space. The ray tracing algorithm also allows conclusions about the intensity distribution of light. For the development of 3D computer games, this means that the illumination of 3D objects and shadow casts can be represented extremely realistically. Meanwhile, surface technology makes use of this technology by calculating the distribution of light intensity in three-dimensional space using volume emitters, complex lamp arrangements or component geometries. Irradiation arrangements can thus be optimized and the necessary irradiation doses can be calculated precisely.

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM