Alternative materials and methods for energy storage

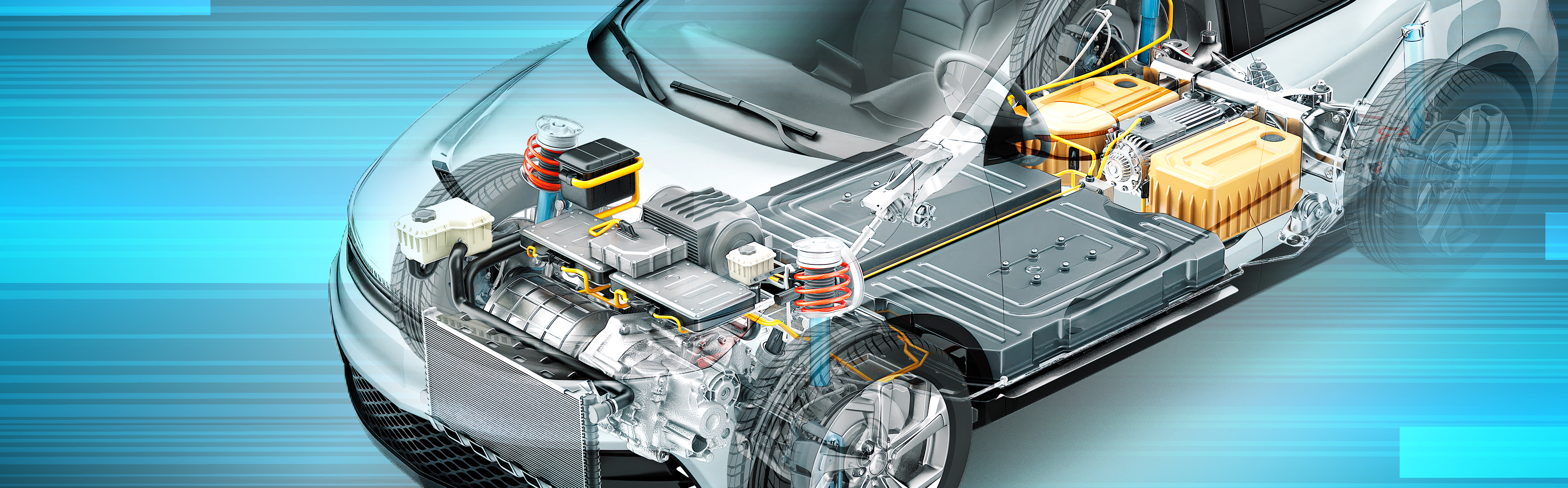

Sustainable battery technologies are steadily gaining relevance and are essential for a cost-effective, environmentally friendly and non-hazardous technology. Due to growing environmental awareness, there is an increasing focus on sustainable manufacturing processes. Furthermore, due to resource scarcity, market-leading lithium-ion batteries (LIBs) cannot cover every area of use and alternative battery cell technologies, such as zinc- and sodium-based systems, are needed.

Due to the expansion of battery production in Germany, the raw material requirements for lithium, cobalt and other metals are increasing, thus exacerbating ecological risks due to raw material extraction. As a result of the scarcity of resources and the CO2 footprint in particular, it is important to consider the entire value chain, from materials and production technology to efficient battery use and recycling.

Environmentally friendly cell production

Currently, extremely harmful solvents are being used in cell production, especially for the production of electrodes for lithium-ion batteries. These have to be recovered during production by means of energy-intensive process steps. The use of exclusively water-based solvents that enable more efficient drying or the adaptation of a solvent-free manufacturing process that does not require a drying step can save investment and operating costs. On top of this, these methods have a positive effect on CO2 emissions.

Zn- and Na-ion systems become more important

Lithium-ion technology in various forms represents the state of the art in areas such as consumer electronics and electro vehicles, which are in high demand today. Nevertheless, global reserves of the alkali metal are limited and mining is costly and not very environmentally friendly. Furthermore, cobalt and nickel are both required for the electrodes of lithium batteries, both of which are metals that are also mined under problematic conditions or are toxic.

Alternative technologies that are inexpensive, non-toxic and highly safe are therefore of overriding interest regardless of their application. Alternatives include Zn-ion and Na-ion systems. These are sufficiently and readily available, do not require cobalt or nickel, and the necessary manufacturing processes can be transferred to conventional battery production.

Online analysis of the battery condition

Another important contribution to sustainability is an adapted operating strategy for energy storage systems. This requires new methods for the online determination of the health of the battery cells, which is necessary for optimal and long-lasting safe operation. Dynamic impedance spectroscopy and data-based analysis processes using AI methods offer great potential in this area.

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM