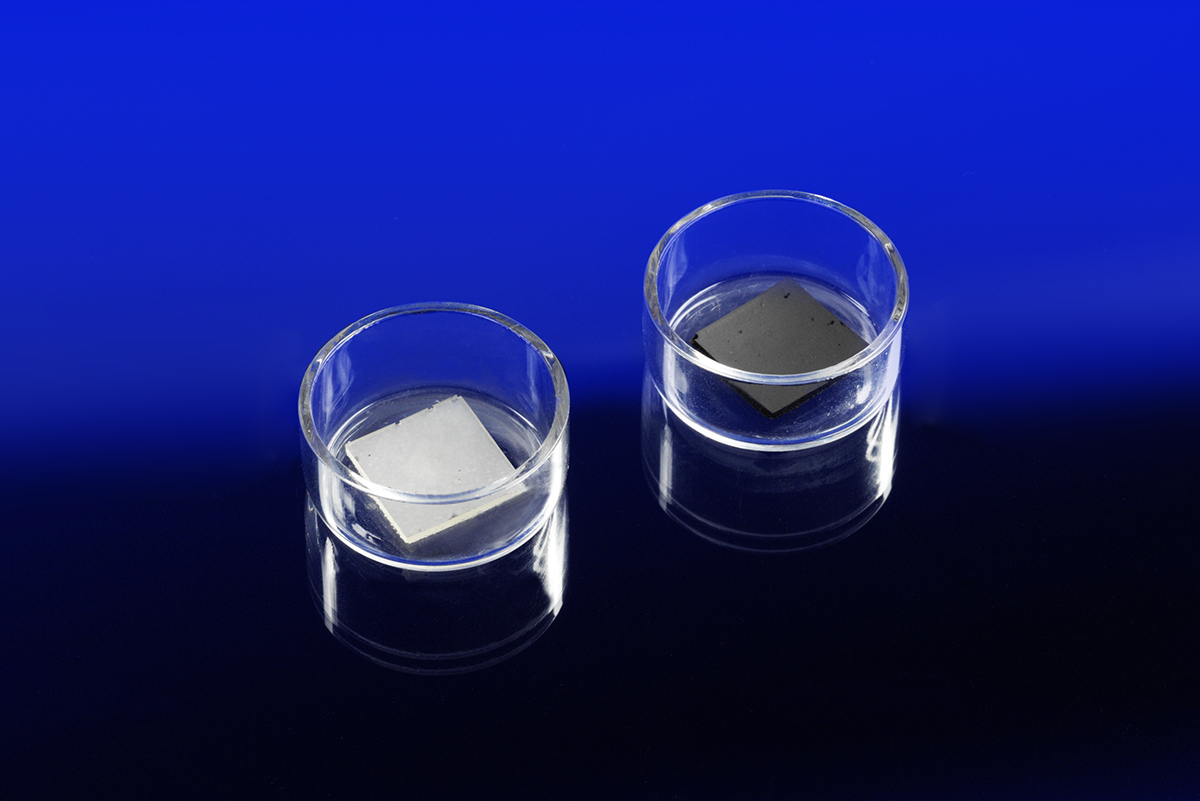

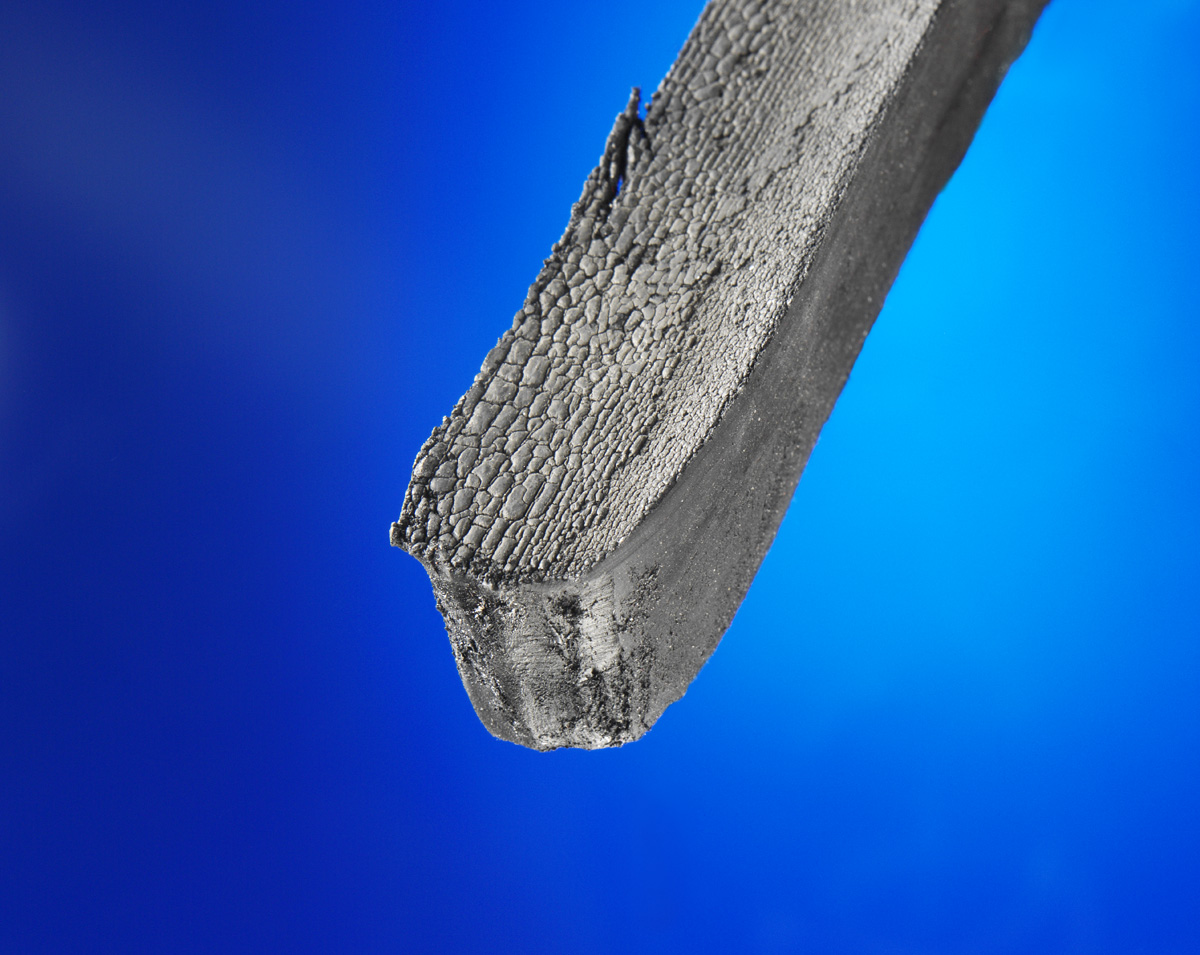

The aging of bonded joints begins immediately with their manufacture. External stresses are decisive for their speed and thus their significance for the bonded component. The visible or measurable manifestations of aging are very diverse. For example, the glass transition temperature can decrease due to the degradation of polymer structures or increase due to plasticizer diffusion as well as incorporation of stiff molecular structures into the polymer chains. Specific functions of the adhesive, e.g. conductivities or damping, may deteriorate and / or the bond strength may drop. At Fraunhofer IFAM, we are investigating the aging of adhesives in order to sustainably improve/ensure the longevity of bonded joints.

Improving the longevity of bonded components

The number of possible aging processes is large. Not all of them are relevant for every bonded joint. Formally, a distinction is made between chemical, physical and biological aging. The simultaneous occurrence of different aging mechanisms, some with different effects on certain adhesive properties, often results in very complex aging phenomena that make it difficult to make a clear statement about what has happened to the adhesive or the bonded joint.

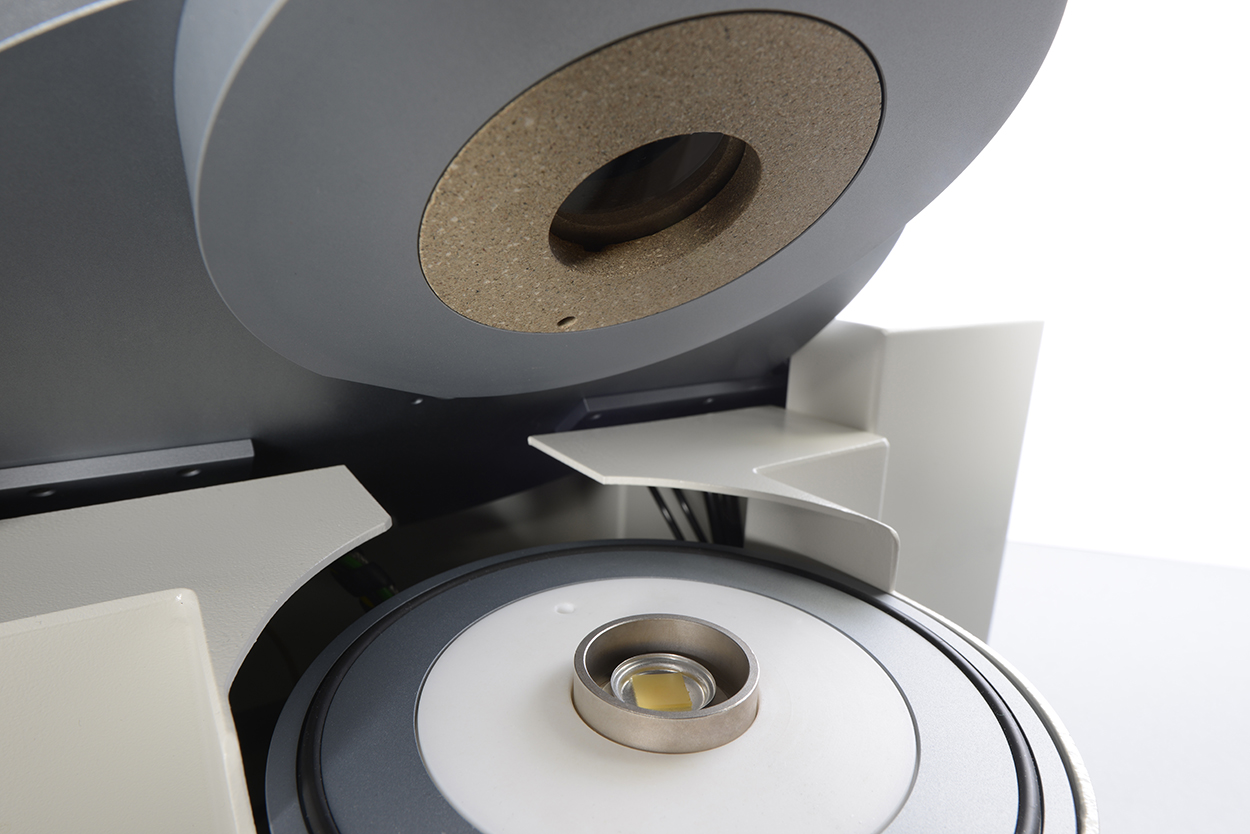

One focus of our work is the investigation of the aging behavior of adhesives and bonded joints. In this context, we are concerned with both the elucidation of aging mechanisms and the creation of models to predict the aging of adhesive bonds. For this purpose, we use, among other things, the kinetic analysis of aging reactions. Another focus is on the development of measurement methods to obtain information on the aging behavior of the adhesive as early as possible.

The aim is to understand the aging of adhesives and bonded joints and to use this knowledge to sustainably improve the behavior of the bonded joint in the application. This concerns both the adhesive composition and different aspects of the bonded joint. With our understanding of the aging of adhesives and bonded joints, we want to contribute to a controlled longevity as well as to an estimation of the lifetime of bonded components. With our know-how we can improve not only the safety but also the sustainability of bonded joints.

We will be pleased to support you in the following questions:

- Characterization of the effects of aging

- Detection of aging mechanisms

- Selection of methods to investigate aging behavior and appropriate adaptation to the requirements of the bonded joint

- Description of the rate of aging using kinetic models / determination of kinetic parameters

- Preparation of predictions of aging behavior based on kinetic models

Your contact person on the subject of adhesive aging:

Dr. Jana Kolbe heads the "Adhesives and Analytics" group in the "Adhesives and Polymer Chemistry" department. The team works in various publicly funded as well as bilateral projects. These involve both adhesive formulation and methods for characterizing the aging behavior of adhesives and adhesive bonds (e.g. "Method development for quantitative evaluation and prediction of aging of bonds under [high] temperature stress") and analytical topics (e.g. "Influence of aging of adhesives on the cleanliness and biocompatibility of surgical instruments" or "Definition and determination of rheological properties critical for micro-application of adhesives").

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM