In the corrosion testing laboratory at Fraunhofer IFAM, various test methods are available for you - for aviation, as well as for automotive and maritime technologies, and for all other applications in which corrosion protection is important. Thus, you benefit not only from the expertise of our personnel in the field of corrosion protection, but also from the diversity of our capabilities.

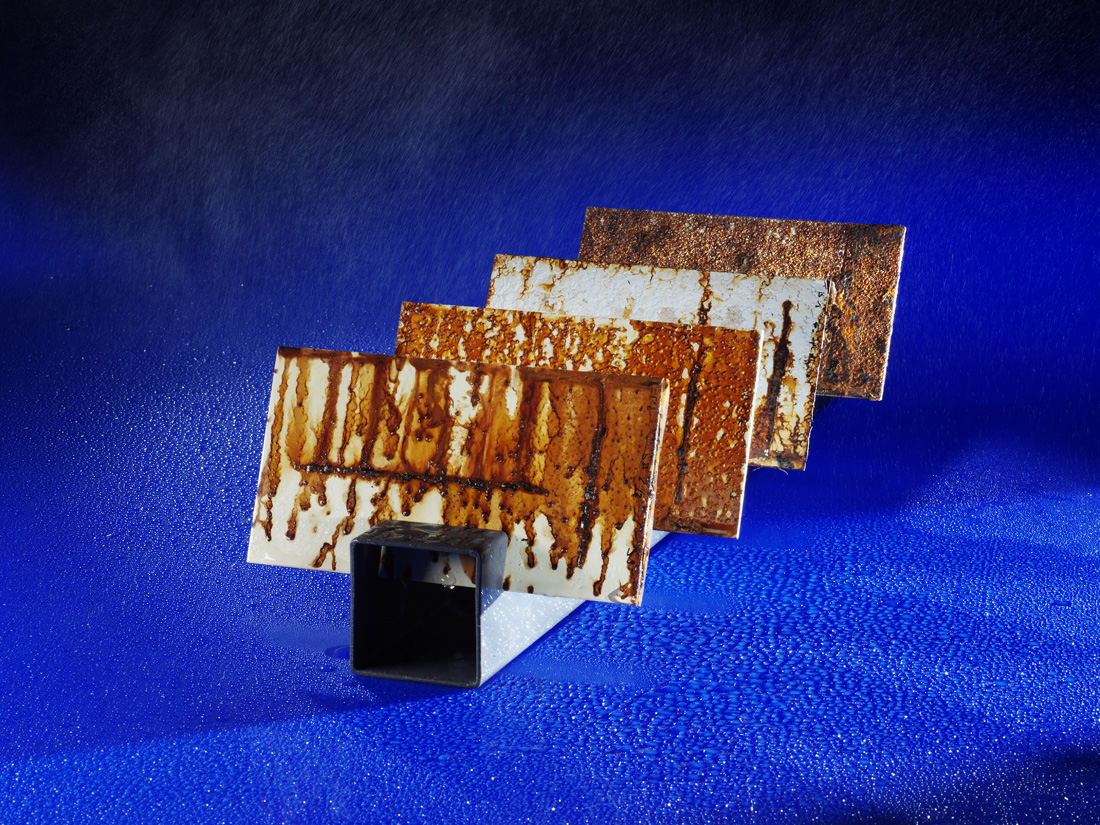

The corrosion testing laboratory at Fraunhofer IFAM is, among others, accredited for salt spray testing according to Nadcap and DIN EN ISO/IEC17025 in accordance with DIN EN ISO 9227 (NSS) and has tests for determining resistance under cyclic corrosion conditions (DIN EN ISO 11997-1), tests for coating systems as well as performance test methods for structures in the offshore sector (DIN EN ISO 12944-9).

An overview of all the tests we can perform for you can be found here.

We can test your corrosion protection - and more

Have you already provided your own sample material with corrosion protection and would like to have the material tested under certain conditions? No problem - but even if you are still in the early stages, Fraunhofer IFAM is your ideal counterpart since our experts also develop their very own surface pretreatment methods.

We combine expertise in materials science with the accredited test methods in our laboratories to provide you with the best possible advice. In addition, we also provide special methods in the field of electrochemical testing, which allows us to obtain results after a shorter period of time, since the mechanisms and beginnings of corrosion formation can be detected even before macroscopic damage becomes visible.

This includes i.a.:

- Classical electrochemical measurement methods (measurement of galvanic currents and current density / potential curves).

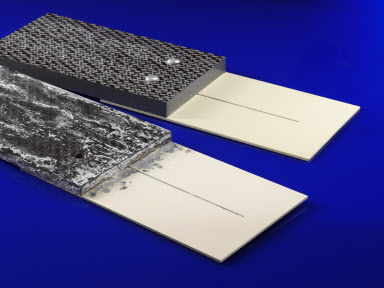

- Modern high-ohmic methods for polymer-metal systems such as coatings, bonded joints, and fiber reinforced plastics (electrochemical noise analysis (ENA), electrochemical impedance spectroscopy (EIS))

- Scanning celvin probe, electrochemical measurements for hydrogen permeation

Expertise for various types of corrosion and corrosion protection

Our experts adapt to your requirements and can always take the most diverse types of corrosion into account - from corrosive infiltration of organic coatings and adhesive bonds, to galvanic corrosion, pitting corrosion, or filiform corrosion.

Furthermore, Fraunhofer IFAM can handle different materials, for example the corrosion protection of metals such as steel, aluminum, magnesium, or titanium, as well as additively manufactured metallic components.

Subsequent to the corrosion test, further analytical procedures are possible at Fraunhofer IFAM for the assessment of damage.

In addition, new concepts for the corrosion protection of coatings can be developed together with the customer.

Advice on test methods and recommendations for corrosion protection from a single source

Thanks to its expertise in materials science and process engineering, Fraunhofer IFAM is able to provide recommended actions beyond tests in order to achieve the desired goal. You can be sure of our qualified and industry-independent advice and receive a solution for your specific testing objectives.

In addition to the corrosion testing laboratory in Bremen, Fraunhofer IFAM also has a corrosion testing facility on Helgoland with the possibility of including outdoor weathering and seawater exposure in our tests.

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM