Environmental simulation for testing and inspection of anti-ice coatings

For the characterization of surfaces, laboratory tests under reproducible icing conditions are necessary to investigate ice formation and ice adhesion strength. This provides material developers with initial information on the performance of the surfaces. Fraunhofer IFAM determines the potential of newly developed icephobic coatings in application-specific laboratory tests.

Ice formation and ice adhesion in reproducible laboratory tests

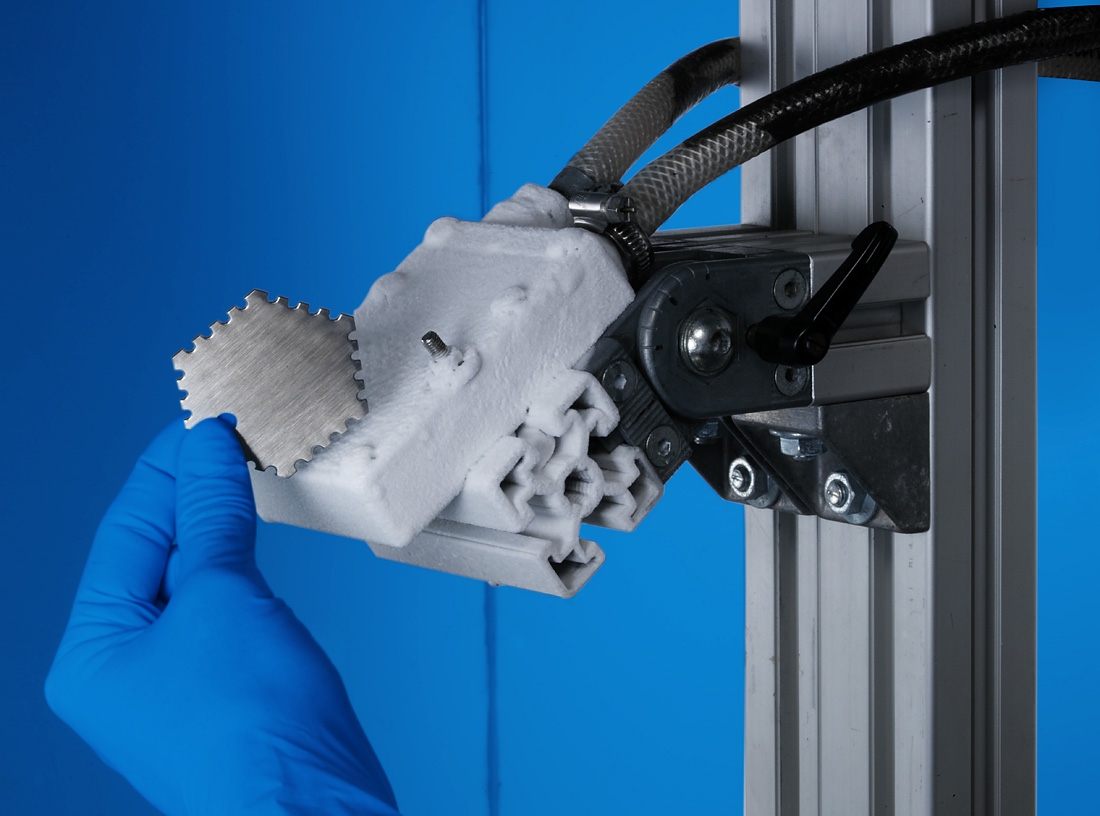

In ice chamber tests, ice rain or ripe ice conditions are simulated and ice formation is evaluated in comparison with reference materials. Ice adhesion is determined, for example, using centrifuge methods or the ice scraper. The tests can be combined with standardized aging procedures (e.g. for UV weathering, chemical or mechanical resistance). Our offer is aimed at customers who want to have their own material developments investigated with regard to an anti-ice function or at potential users of anti-ice coatings who want to obtain an initial assessment of selected technologies.

Ice laboratory and ice wind tunnel for simulating environmental conditions

Further tests under realistic conditions serve to evaluate materials in the overall technical system. Evidence of optimized performance or increased energy efficiency is a prerequisite for their implementation in technical applications.

Fraunhofer IFAM operates an icing wind tunnel for the simulation of icing conditions, relevant for aviation and wind energy. High velocities and the supercooled water droplets characteristic of clouds allow realistic results on performance in the targeted application. In addition, weathering tests under real environmental conditions are carried out on the Brocken at an altitude of 1141 meters. The test facilities are available to our customers to plan and conduct joint test campaigns.

The development of anti-icing coatings and icing tests is part of the work on functional coatings carried out by the "Paint and Lacquer Technology" department at Fraunhofer IFAM. The experience gained from publicly funded projects in the application fields of aviation, wind energy, automotive and rail vehicle construction, as well as refrigeration and air conditioning technology is used by Nadine Rehfeld to make significant contributions to international committee work on test standards and the definition of design and material specifications.

Current projects for wind energy

Fraunhofer IFAM is involved in the IEA WIND TCP Task 19 "Wind Energy in Cold Climates" and is developing technical reports and guidelines for wind turbines in cold climates in this international working group.

In the standards committee NA 002-00-16 AA "Coatings on rotor blades for wind turbines", Fraunhofer IFAM is designing future test standards for functional coatings in collaboration with partners from industry and science. For example, specifications for ice adhesion tests are being developed (ISO/DTS 19392-6).

Publications

Our experts research and develop test methods for anti-icing coatings. Read more in our current publications.

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM