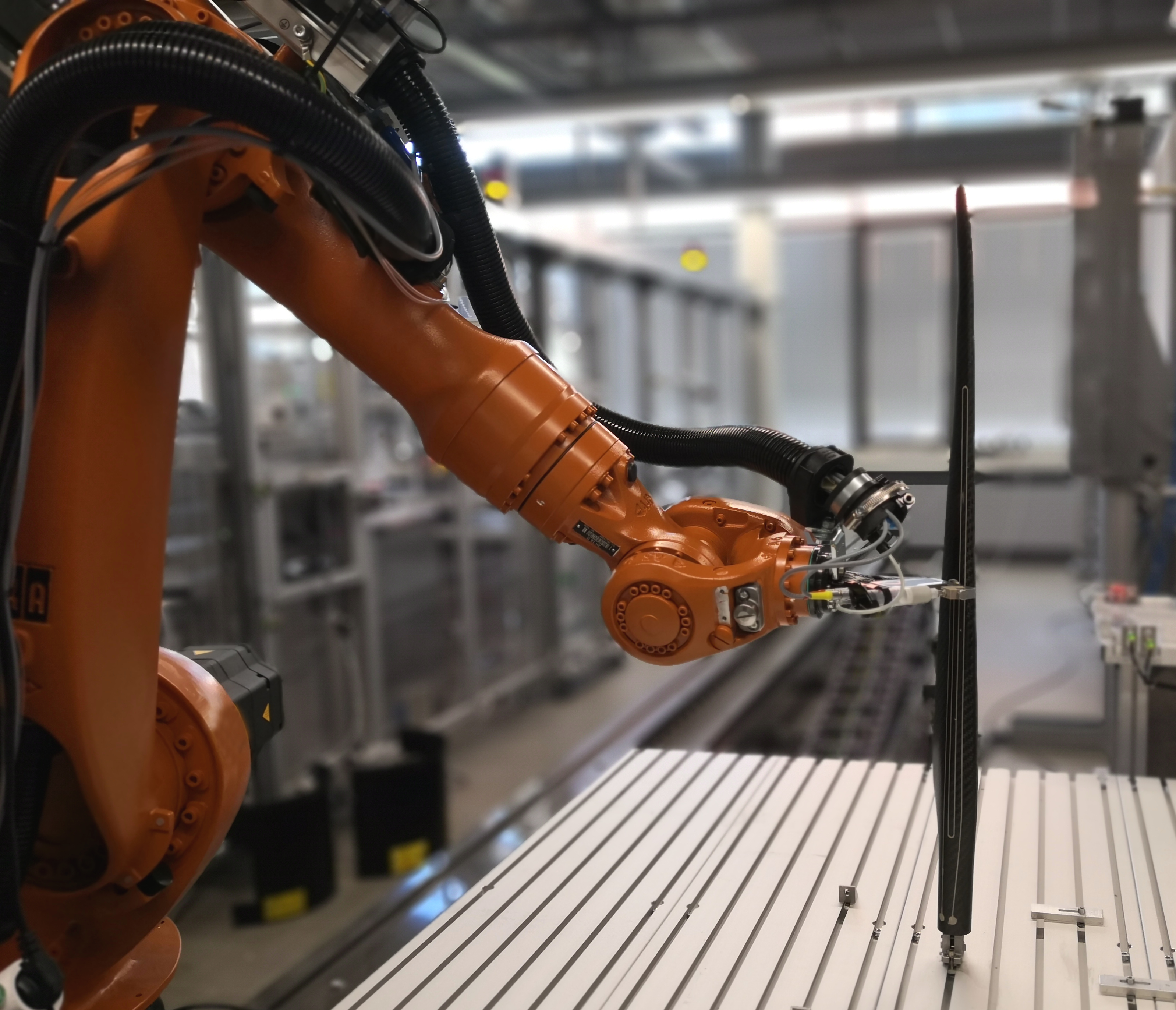

Printing of large components

The use of industrial robots and 5-axis gantries systems makes it possible to print functions such as sensors or heaters on components with complex surfaces exactly where they are needed. Various printing technologies such as aerosol jet or dispensing can be used to print structure sizes ranging from a few micrometres to several metres. The systems at Fraunhofer IFAM can thus provide component sizes ranging from a few millimetres to 10 metres with a variety of different functions, such as conductor tracks, with pinpoint accuracy.

High level of automation

5-axis portal systems and industrial robots enable the functionalization of complex and large surfaces as well as 24/7 industrial production. Established production technologies are therefore used for manufacturing of new types of products. For example, smartphone antennas can already be printed directly on the inside of the housing, enabling a more compact design with a higher degree of automation in production. In addition, the functionalization of increasingly complex design elements, such as multiple curves, can be implemented using portal systems and robots.

Efficient and resource-efficient due to Functional Printing

The functionalization of components and surfaces using functional printing offers significant advantages over other technologies. On the one hand, material is only applied where it is necessary during the printing process. This eliminates the expensive post-treatment processes that are based on environmentally harmful chemicals. On the other hand, the digital approach enables the production of a wide range of product variants, including individualised unique products, on the same system.

Functional printing can thus be operated economically on a small scale, on an industrial scale, and under strict environmental regulations. This opens up the possibility of production in Germany, which offers short supply chains and high flexibility.

Functionalization of complex and large surfaces

Three different systems are used at Fraunhofer IFAM for the functionalization of complex and large surfaces: a Kuka KR16 on a ten-metre-long linear axis and a UR5e from Universal Robots are available for the functionalization of large and medium-sized components. These can carry a wide variety of print heads and can therefore follow and print on almost any component surface. The 5-axis gantry system with PJ 15X single print head from Neotech AMT is used for smaller components. Various printing, pre- and post-processing methods can also be used on this system.

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM