Production of electrodes and battery cells

The production of battery cells comprises a complex process chain from the powder to the cell. There are many interactions between the individual process steps. Changes to individual process steps therefore often lead to changes along the entire chain. This is all the more true the further up the chain the respective step is located. The use of novel materials, for example, generally requires at least the development of adapted components and matching cell concepts. Fraunhofer IFAM therefore always focuses on the complete consideration of all aspects - from the powder to the cell.

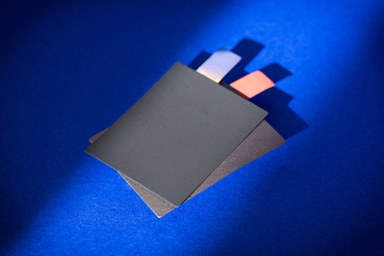

Electrode production

The performance of electrical energy storage systems is decisively influenced by the quality of the electrodes. According to the current state of the art, they are manufactured by means of a film casting process in which flowable masses of active material, conductivity additives and binder are applied to electrically conductive carrier materials. The process chain from the starting materials to the usable electrode comprises the process steps of mixing and dispersing, the wet application itself, subsequent drying and, if necessary, calendering (densification). Each individual step must be adapted to the materials used and optimized in terms of the targets and requirements for the electrode.

New materials and battery technologies often require the development of new manufacturing methods and processes. To this end, we research and develop in the areas of:

- Mixing and coating technology incl. scalability

- Recipe development and paste formulation for film casting and printing (printed batteries)

- PVD/CVD processes (physical and chemical vapor deposition): Thin film electrodes, alloy anodes, Li-free anode concepts

- Molding process under inert conditions e.g. by means of extrusion (laboratory for solid-state batteries)

- Fabrication of three-dimensional gas diffusion electrodes with adapted wetting properties

The processing scale depends on the materials used and the type of question.

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM