Identify critical areas in the casting and minimize casting defects (e.g. shrinkage cavities)

In the case of casting defects, a distinction can be made between defects which are primarily determined by mold filling and those which are primarily influenced by solidification. Depending on the process, the former include introduced oxides, oxide skins, gas porosity, etc., while typical examples of the latter are shrinkage cavities, residual stresses and distortion.

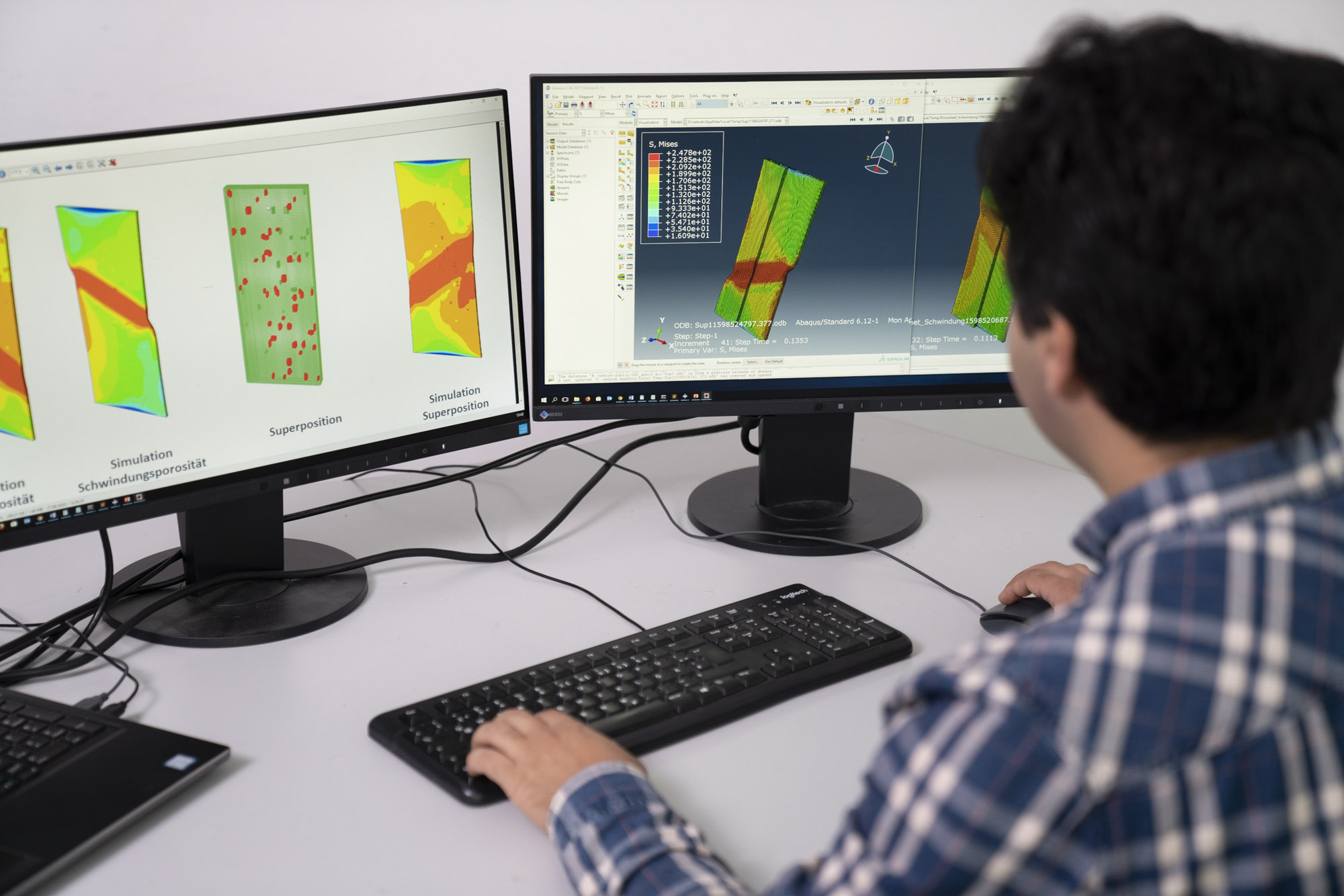

By numerically mapping mold filling and solidification, our casting technology experts can not only identify critical areas in the casting, but also minimize their influence on component behavior by adjusting process parameters or geometries accordingly. The aim of current research activities at Fraunhofer IFAM in this area is to gain a deeper understanding of the relationships between process and component properties. For example, by improving material utilization and reducing scrap rates, it is possible to identify and exploit the potential for a holistic assessment of the sustainability of cast components.

Finite Element Method (FEM) offers possibilities for optimization of component variants already during simulation

Alongside the casting design and process simulation, the castings are designed with regard to their functional properties. Depending on the application, the focus may be on structural properties such as strength and stiffness or functional variables such as electrical or thermal conductivity - the latter, for example, in the case of components for the electric powertrain (including cast short-circuit rings etc. for electric motors or cooling channels in electric motor, power electronics or battery housings).

Here, the finite element method (FEM) offers the possibility of evaluating and optimizing component variants in virtual experiments already during development. We can also draw on a link between process and component simulation, which enables us to include process-related property variations in the evaluation.

Diverse potentials for lightweight construction

A central paradigm of lightweight design is to use the right material in the right place. In addition to technological prerequisites, such as those created at Fraunhofer IFAM in the areas of composite and hybrid casting, the implementation of this approach requires suitable optimization tools. In combination with the finite element method, these allow the full lightweight potential of the respective component to be exploited.

However, completely different boundary conditions apply to the resulting multi-material components, which must be taken into account both in the mapping of the casting process and in the simulation of the component behavior. This applies above all to the transition zone between the materials concerned. In order to correctly represent the behavior of this zone, special boundary layer models are being developed at Fraunhofer IFAM on the basis of tailored experiments. These models describe both the thermal and the mechanical behavior of the composite zone of such components and provide parameters which can be directly included in the process and component simulation. Further developments aim at a prediction of such component properties from the process simulation.

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM