Inline blasting processes for cleaning, activation and repair of surfaces

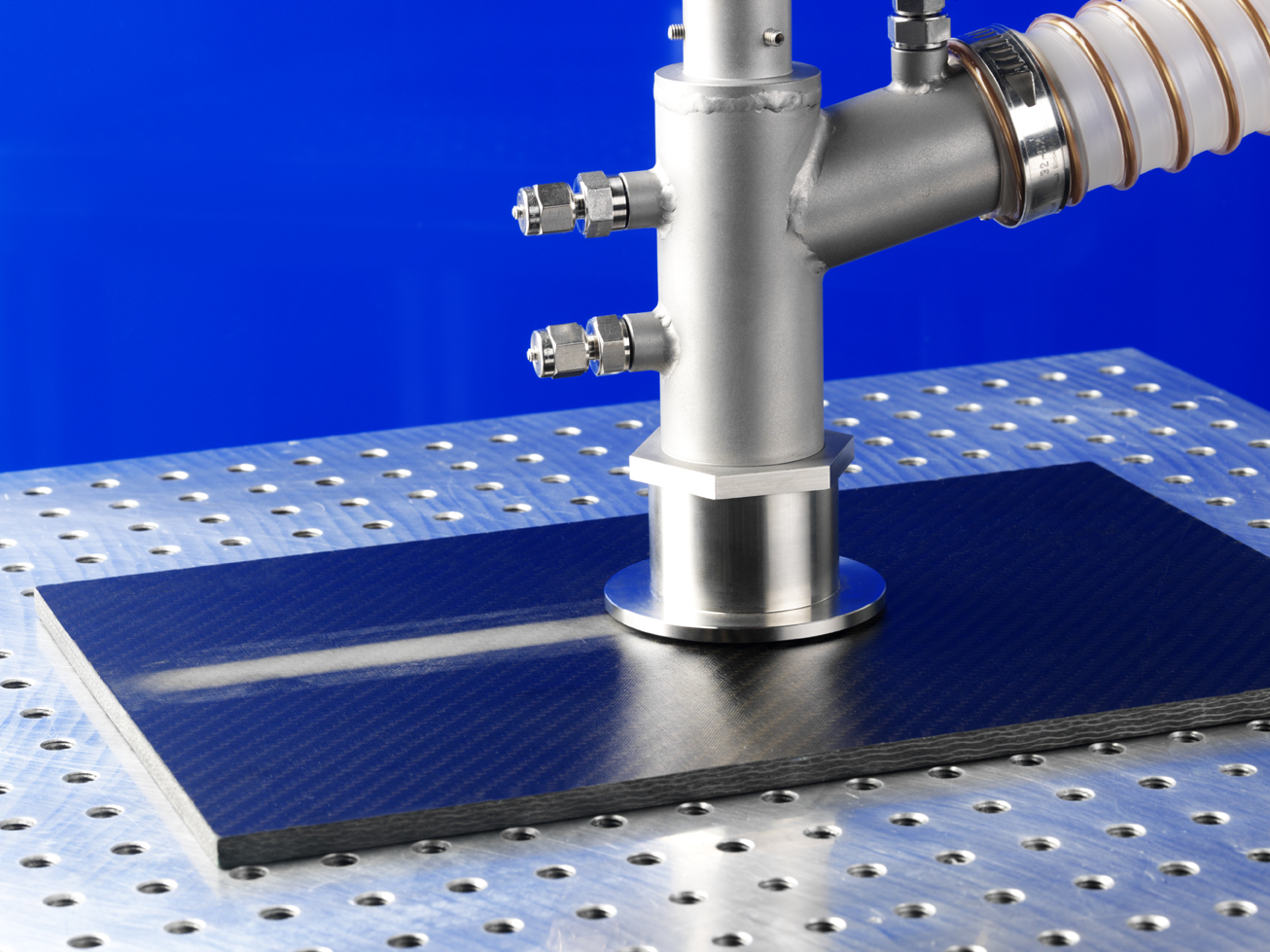

Classical compressed air blasting requires the use of blasting booths or complex temporary protective measures to clean surfaces or remove coatings. Much simpler is to use compact and mobile vacuum suction blasting prior to, for example, adhesive bonding, painting/lacquering, coating or repair work. In this method an industrial vacuum cleaner generates a reduced pressure in a closed head through which the blasting media is accelerated onto the surface and after the blasting process is immediately extracted again by and towards the vacuum cleaner. This means that dust-free blasting processes can even be performed in-line under sensitive production conditions.

Vacuum suction blasting can replace conventional compressed air blasting and can be used instead of manual and automated local sanding/grinding processes. By customizing the blast heads and process conditions, the process can meet a wide range of customer requirements.

Application examples of vacuum suction blasting

- Local cleaning and layer removal from fiber reinforced plastics

(FRPs such as CFRPs, GFRPs) and coatings for repair applications - Cleaning and activation of fasteners

(e. g. for aircraft manufacture, aircraft repair) - Cleaning and activation of large structures in rail vehicle construction

- Contact-free blasting of large-area substrates

(e. g. solar cells, sheet materials)

Advantages of the process

- Mobile and inline capable process

- Fast, low-cost process

- No dust emissions

- Enhanced use of resources due to local, needs-oriented surface pre-treatment

- Simplification of the production due to no need for blasting booths

- Easy automation and process monitoring

- Improved workplace safety and process efficiency due to local pretreatment with integrated extraction

- Can be used on a wide range of materials, and also on composites such as polymers and metals

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM