Fused Filament Fabrication (FFF) as a process for the generative production of plastic components is widely used in both industrial and private applications. This is due to its ease of use, wide range of materials and low-cost, affordable plant technology.

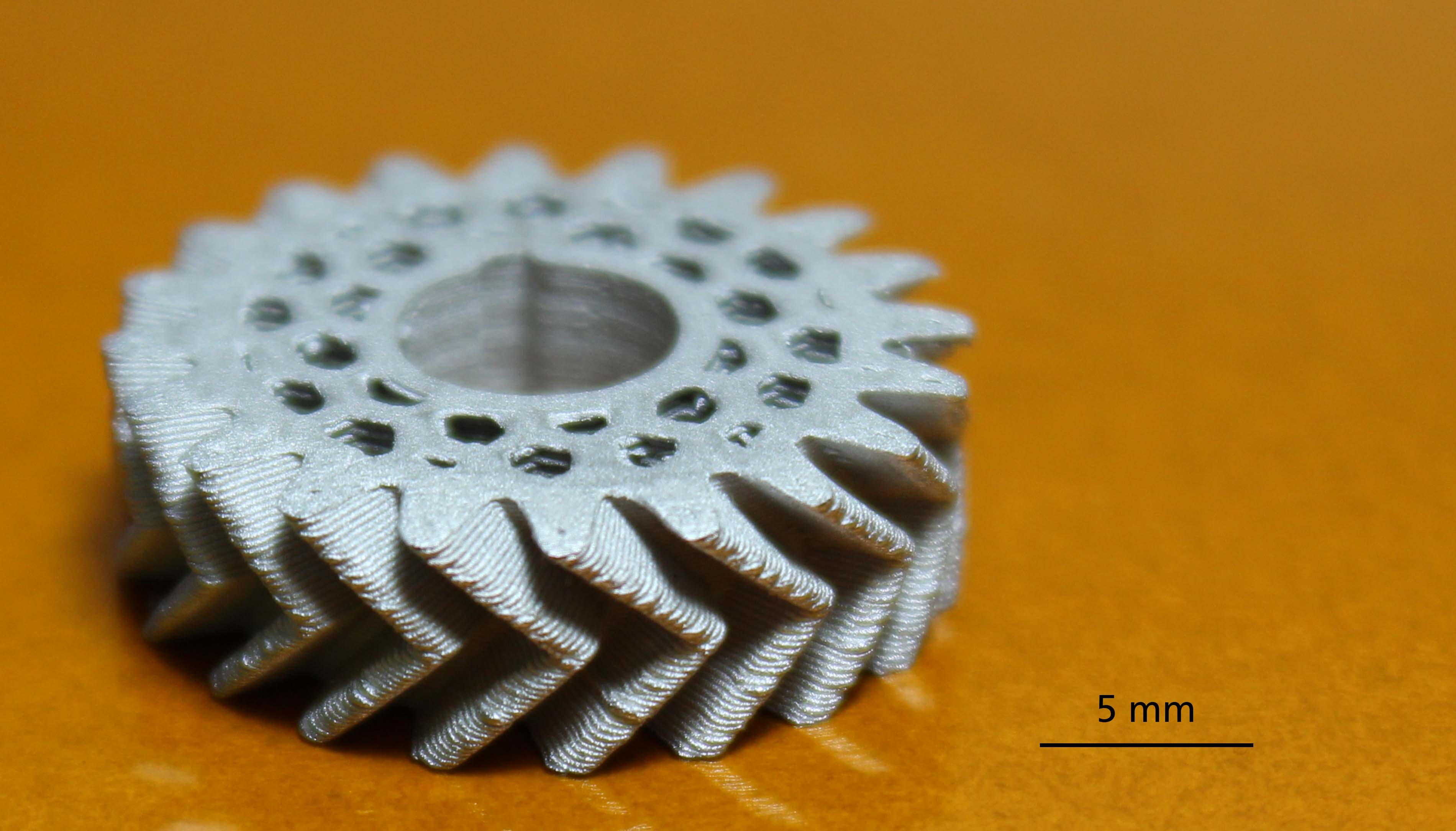

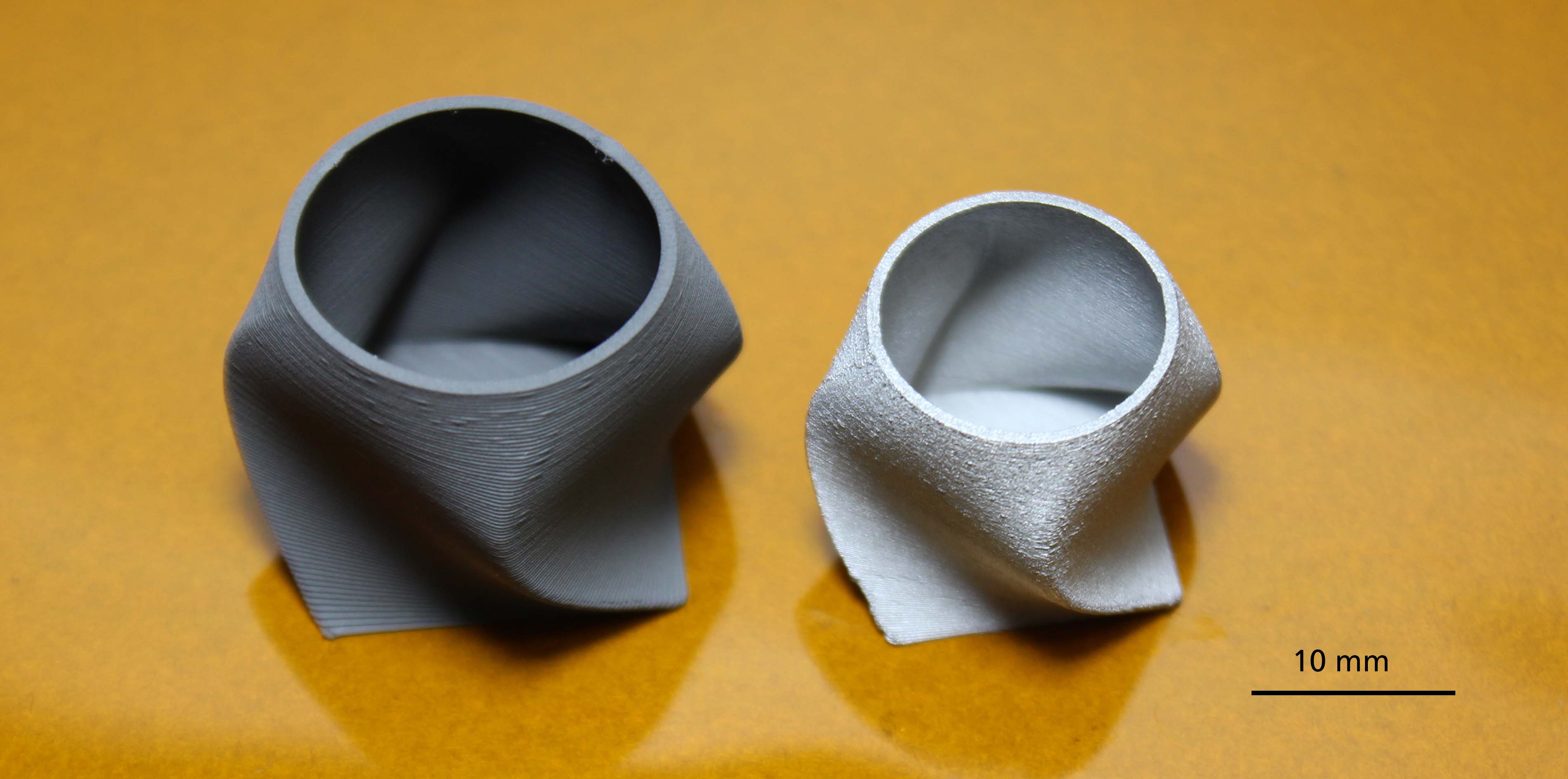

Fraunhofer IFAM is now expanding the range of materials to include metallic components that were previously not possible. This is achieved by the use of newly developed filaments containing metal powder with high filling degrees. The filament is printed to form a green part consisting of plastic and metal powder and can then be sintered to a plastic-free, metallic component using a heat treatment process analogous to conventional sintering processes such as metal powder injection molding (MIM). The process is characterised in particular by its relatively low investment costs for a complex free-form design comparable to other processes. Due to its proximity to the injection moulding process, this tool-less method is suitable for the production of prototypes, special components and small series, whereby it uses commercially available 3D data formats.

In context of the joint project "AMCC-Line" within the SAB project sponsorship, Fraunhofer IFAM is currently involved in the production of metallic filaments and the development of process and heat treatment strategies.

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM