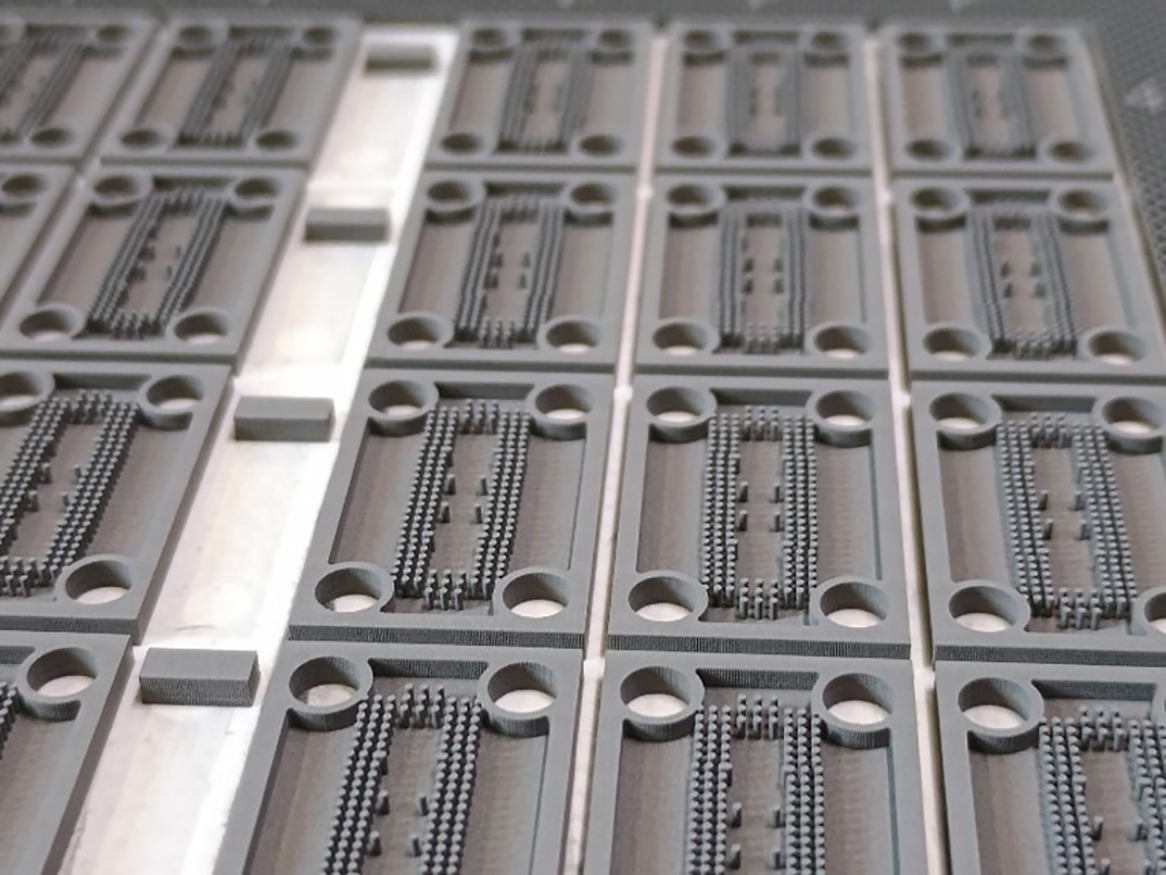

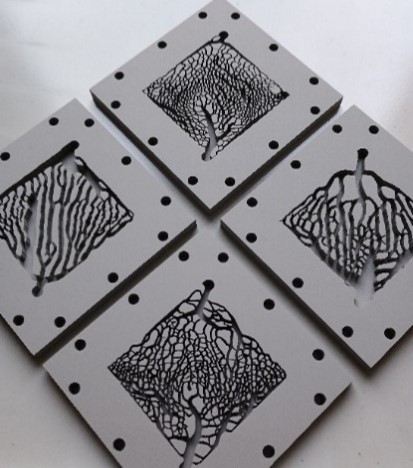

Fraunhofer IFAM Dresden has developed an innovative and mass-market-ready process that enables the production of high volumes of precision metal components. To manufacture the components, a particle-filled slurry is transferred through a structured tool (screen) and then dried. This printing process is repeated until the target height of the component is reached or the geometry to be printed is changed by changing the screen. Two printing systems are available for the production of the components. After the printing process, the component is compacted using thermal processes (debinding + sintering).

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM