Lightweight Materials for Machine Construction

The use of highly damping lightweight construction materials enables the massive reduction of moved masses in machine construction. Low mass is a great benefit for moved components especially. Lower mass of moved components demands smaller engines and actuators and enables slender dimensioning for lower forces. Benefits of the use of highly damping lightweight construction materials can be:

Higher machining precision

Structural vibrations are developed, for instance, by operating engines and actuators and by overshooting of accelerated construction components. The vibrations can propagate and disturb the precision over wide distances particularly in light and high stiff constructions. Highly damping lightweight construction materials decrease the vibrations where needed.

Shorter cycle times

An increase of structural damping permits higher accelerations at unchanging precision.

Longer life cycle

Vibrations induce alternating loads. Thus, vibration fractures at grooves and in corrosive environment especially are caused. This shortens the life cycles of machines and components. To dampen the vibrations under the fatigue endurance limit extends the life cycle significantly.

Lower abrasive wear – better surfaces

The vibrations, which are generated at the tool center point, lead to grooves at the surface and to extended abrasive wear. Damping of these vibrations at the tool holder and at the machine base leads to better surfaces and longer life cycles of the tools.

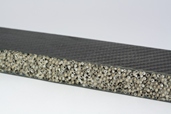

The highly damping lightweight construction materials are used as cores of sandwich and profile constructions. Both carbon fiber composites as well as steel or aluminum sheets can be used for the backing. The hollow sphere structures can be soldered at the sheets to obtain sandwiches. The sandwiches can be welded without destroying the hollow sphere structures. The highly damping lightweight construction materials are usually glued in profiles and carbon fiber products.

Additionally, it is possible to use the high damping lightweight construction materials as foundry core. Components cast this way not only get lighter, they also dampen vibrations much more than cast components that lack the highly damping lightweight construction materials.

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM