Sub-project: Material Development and Simulative Optimization for GDL and Bipolar Plate

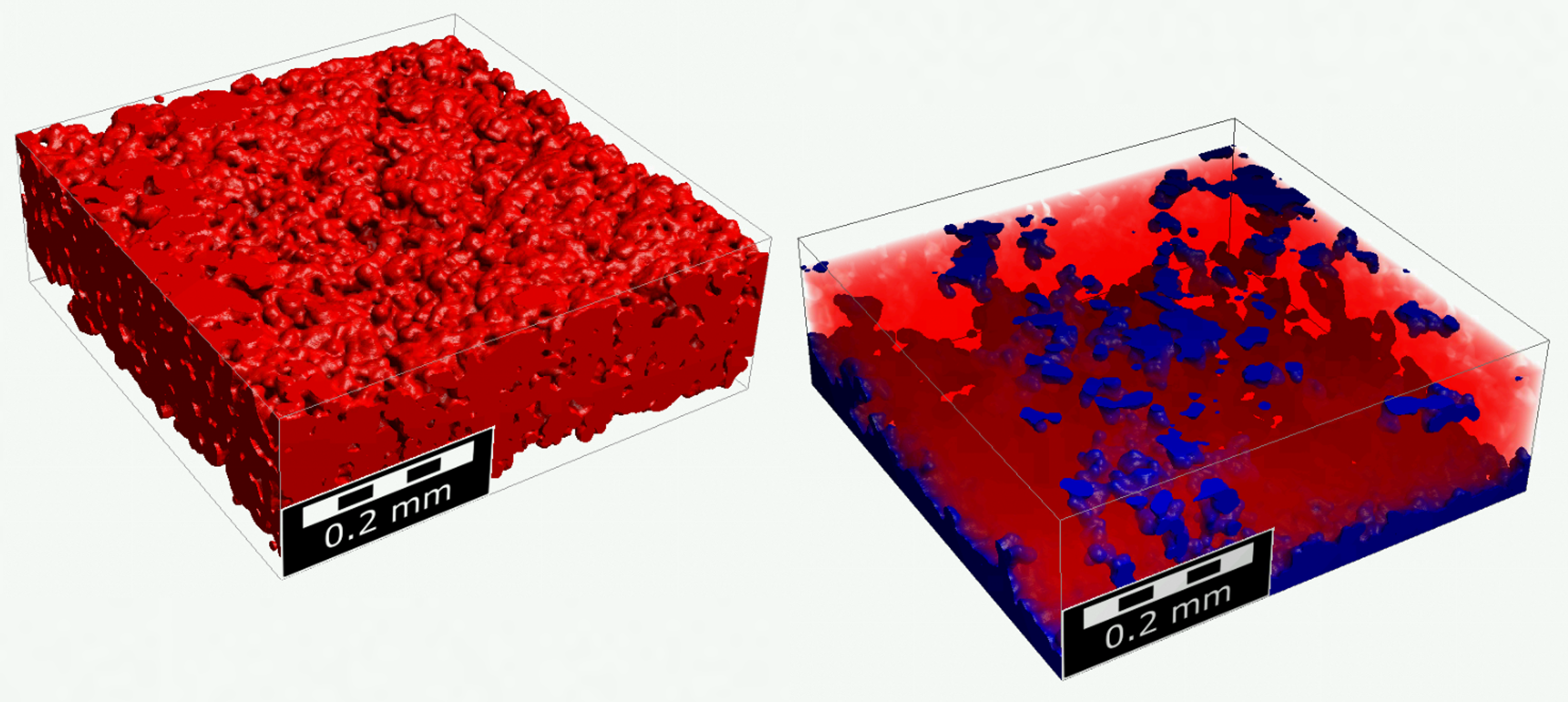

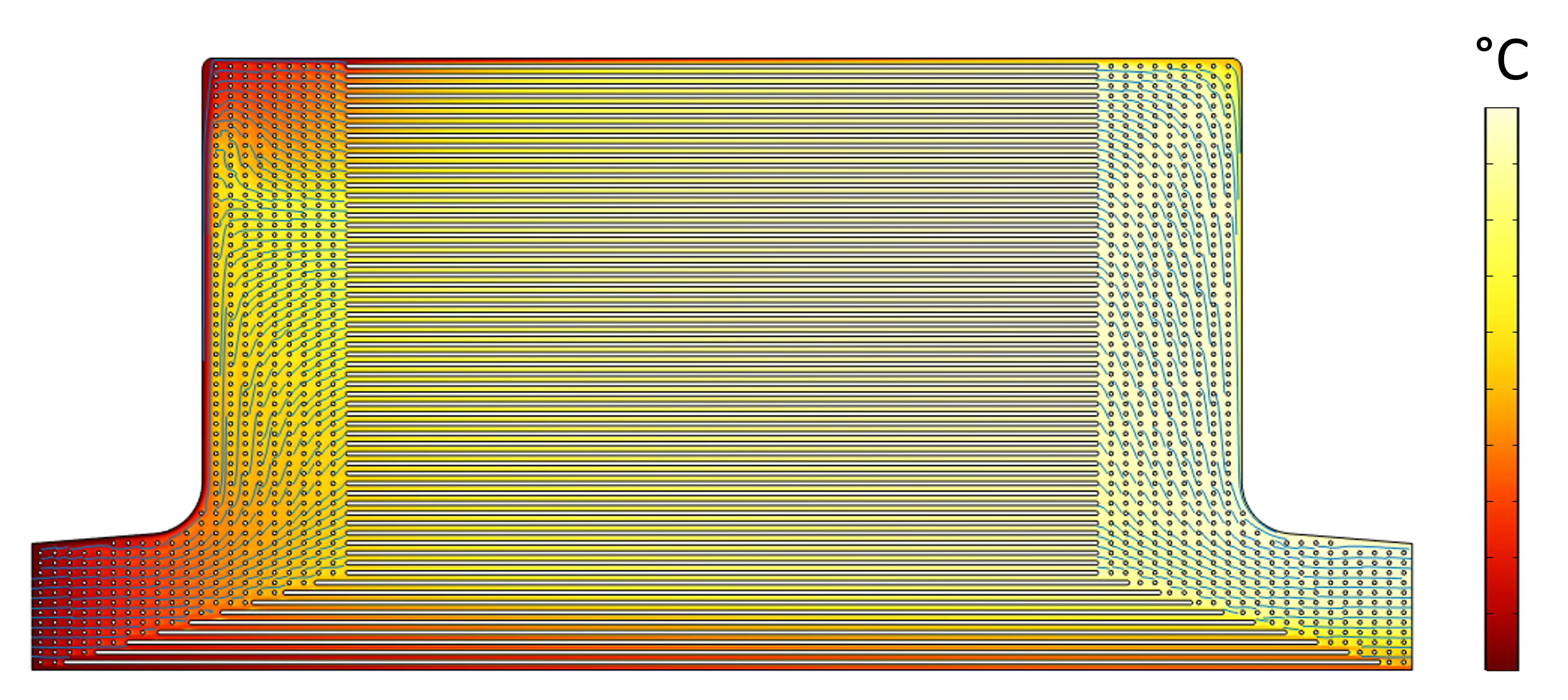

Currently, fuel cells for mobile applications still have considerable potential for improvement in terms of minimizing installation space, reducing manufacturing costs and increasing service life. An important component of the fuel cell stack for all the properties mentioned is the gas diffusion layer (GDL). The GDL is located between the bipolar plate and the electrode and must ensure optimum gas distribution and the removal of water, heat and electricity. The GDL currently consists preferably of porous graphite mats or graphite plates, which still have deficits in terms of mechanical stability, service life and costs.

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM