For political, security, and energy strategy reasons it is vital to guarantee the availability of raw materials. Hydrogen is one of the irreplaceable base chemicals of the chemical industry and, being an energy source, is one of the central pillars of the shift to renewable energy. The CO2-neutral production of hydrogen can only be achieved industrially via the electrochemical splitting of water in an electrolyzer that is powered by renewable energy sources.

High-Efficiency Electrode Materials for Gas-Generating Reactions

Improving electrolysis technology for "green" hydrogen

The further development of electrolysis technology has high strategic importance for Germany in order to generate "green" hydrogen for commercial use. At present the conventional way to generate hydrogen is via gas reforming. This is economically favorable due to the availability of natural gas but is accompanied by very high CO2 emissions. Fraunhofer IFAM in Dresden is undertaking development work to improve electrolysis technology for commercial hydrogen manufacture. The main costs (investment costs and operational costs) of electrodes and stacks are the focus. The aim of the development work is to considerably reduce the plant and hydrogen production costs using electrodes that have long-term efficiency.

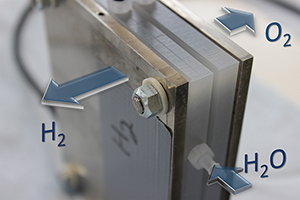

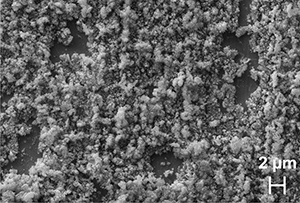

Fraunhofer IFAM in Dresden is evaluating novel gas-generating electrode materials using electrochemical methods – combined with structural analysis. Degradation mechanisms of the electrodes are being elucidated, allowing conclusions to be drawn for improved electrode composition and manufacture. Favorable-cost nanocrystalline electrodes (Fe and Ni alloys) have been developed, whose high catalytic activity can be maintained by activation in the electrolyzer. In addition, the electrode materials are being tested under real conditions in single-cell test stands to gain information about gas bubble transport in the cells. This then allows adaptation of the electrode and cell geometry. The end result is the development of customized electrodes with advantageous gas bubble transport. Our in-depth knowledge of electrochemistry, metallic materials, and production technologies make Fraunhofer IFAM an expert partner for manufacturers of electrolyzers.

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM