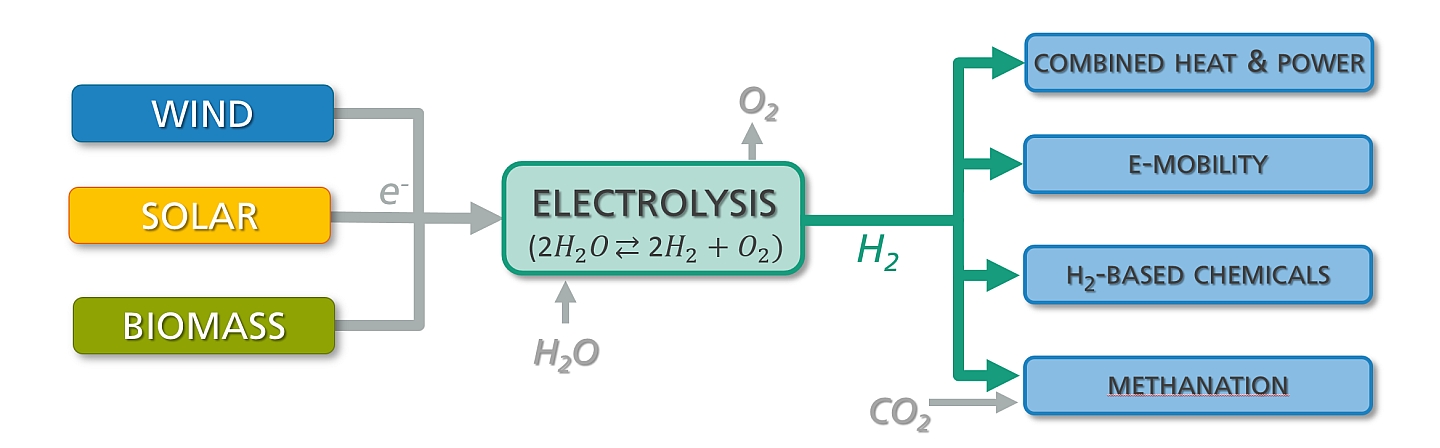

In view of the shortage of fossil energy resources and the ongoing climate change caused by man-made carbon dioxide emissions, the energy industry is facing a radical change. In view of “green” energy technologies, hydrogen will play a leading role as secondary energy carrier if a low-cost and climate-neutral hydrogen production from renewable energy sources like wind or solar power can be achieved. The alkaline electrolysis of water has the potential to fulfill both requirements. However, in the last years only marginal efforts have been made to enhance efficiency and power density of the electrolysis process.

Electrolysis

3D Electrodes

Porous materials offer the possibility to enlarge the active surface area of the electrode and to direct the gas-electrolyte flow. Both aspects depend on the pore structure. At Fraunhofer IFAM Dresden we are able to modify open-cellular metal foams or fleeces so that they form nanocrystalline surfaces which are electrocatalytically very active:

- pore size: 5 - 1200 µm

- porosity: 50 - 95 vol.%

Nanocrystalline Electrodes

The electrocatalytical activity of electrodes and thus the efficiency of the electrolysis process are positively influenced by nanocrystalline electrode surfaces. Such a nanocyrstallinity of metal surfaces can be achieved by certain surface treatments or deposition processes. At Fraunhofer IFAM Dresden, nanocrystalline metal alloys (Fe- and Ni-base), which are produced by melting metallurgical routes, are being developed and tested with regard to their applicability as electrode materials.

Electrochemical and Structural Analysis

Fraunhofer IFAM Dresden is equipped with state-of-the-art analysis tools in order to investigate the electrochemical properties, the surface morphology and the structural properties of the electrode materials:

- Electrochemical analysis

- Cyclic voltammetry (CV)

- Electrochemical impedance spectroscopy (EIS)

- Polarization methods

- Scanning electron microscopy (SEM)

- Scanning probe microscopy

- Atomic force microscopy (AFM)

- Scanning tunneling microscopy (STM)

- Electrochemical STM (EC-STM) and scanning electrochemical potential mapping (SECPM) for in situ experiments in liquids

Lab-scale Electrolyzer

The electrode materials are tested under realistic operation conditions (80°C, 30 m% KOH) to demonstrate their applicability. Therefore, the electrodes are integrated into lab-scale electrolyzer cells. Due to the flexible design of the test system different electrode configurations and operation conditions can be realized:

- Single-cell design

- 20 °C ... 80 °C

- atmospheric pressure

- 5 Normliter-H2 per hour

Literature

C. I. Bernäcker, T. Rauscher, T. Büttner, B. Kieback, L. Röntzsch

A Powder Metallurgy Route to Produce Raney-Nickel Electrodes for AlkalineWater Electrolysis

Journal of the Electrochemical Society, 166 (6), 2019, F357-F363

M. Durovic, J. Hnát, C. I. Bernäcker, T. Rauscher, L. Röntzsch, M. Paidar, K. Bouzek

Nanocrystalline Fe60Co20Si10B10 as a cathode catalyst for alkaline water electrolysis: Impact of surface activation

Electrochemica Acta 306, 688-697, 2019

M. Farjad Ali, H. In Lee, C. I. Bernäcker, T. Weißgärber, S. Lee, S.-K. Kim, W.-C. Cho

Zirconia Toughened Alumina-Based Separator Membrane for Advanced Alkaline Water Electrolyzer

polymers, 14 (6), 2022, 1173

F. Foroughi, C. I. Bernäcker, L. Röntzsch, B. G. Pollet

Understanding the Effects of Ultrasound (408 kHz) on the Hydrogen Evolution Reaction (HER) and the Oxygen Evolution Reaction (OER) on Raney-Ni in Alkaline Media

Ultrasonics Sonochemistry, Vol. 84, 2022, 105979

A. Gabler, C. I. Müller, T. Rauscher, T. Gimpel, R. Hahn, M. Köhring, B. Kieback, L. Röntzsch, W. Schade

Ultrashort-pulse laser structured titanium surfaces with sputter-coated platinum catalyst as hydrogen evolution electrodes for alkaline water electrolysis

International Journal of Hydrogen Energy, Vol. 43, Issue 15, 2018, 7216-7226

A. Gabler, C. I. Müller, T. Rauscher, M. Köhring, B. Kieback, L. Röntzsch, W. Schade

Ultrashort pulse laser-structured nickel surfaces as hydrogen evolution electrodes for alkaline water electrolysis

International Journal of Hydrogen Energy, Vol. 42, Issue 16, 2017, 10826-10833

H. A. Miller, K. Bouzek, J. Hnat, S. Loos, C. I. Bernäcker, T. Weißgärber, L. Röntzsch, J. Meier-Haack

Green hydrogen from anion exchange membrane water electrolysis: a review of recent developments in critical materials and operating conditions

Sustainable Energy Fuels, 4, 2020, 2114-2133

C. I. Müller, K. Ehelebe, S. Loos, L. Röntzsch

Elektrochemische Reduktion von CO2 zu eChemicals: C242

gwf Gas+Energie, 159, 2018, 52–56

C. I. Müller, K. Sellschopp, M. Tegel, T. Rauscher, B. Kieback, L. Röntzsch

The activity of nanocrystalline Fe-based alloys as electrode materials for the hydrogen evolution reaction

Journal of Power Sources 304, 2016, 196-206

C. I. Müller, T. Rauscher, A. Schmidt, T. Schubert, T. Weißgärber, B. Kieback, L. Röntzsch

Electrochemical investigations on amorphous Febase alloys for the alkaline water electrolysis

International Journal of Hydrogen Energy, Vol. 39 Issue 17, 2014, 8926–8937

T. Rauscher, C. I. Bernäcker, S. Loos, M. Vogt, B. Kieback, L. Röntzsch

Spark-plasma-sintered porous electrodes for efficient oxygen evolution in alkaline water electrolysis

Electrochimica Acta, Issue 317, 2019, 128-138

T. Rauscher, C.I. Bernäcker, U. Mühle, B. Kieback, L. Röntzsch

The effect of Fe as constituent in Ni-base alloys on the oxygen evolution reaction in alkaline solutions at high current densities

International Journal of Hydrogen Energy, Vol. 44, Issue 13, 2019, 6392-6402

T. Rauscher, C.I. Müller, A. Gabler, T. Gimpel, M. Köhring, B. Kieback, W. Schade, L. Röntzsch

Femtosecond-laser structuring of Ni electrodes for highly active hydrogen evolution

Electrochimica Acta, Vol. 247, 2017, 1130-1139

T. Rauscher, C.I. Müller, A. Schmidt, B. Kieback, L. Röntzsch

Ni-Mo-B alloys as cathode material for alkaline water electrolysis

International Journal of Hydrogen Energy 41, 2016, 2165-2176

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM