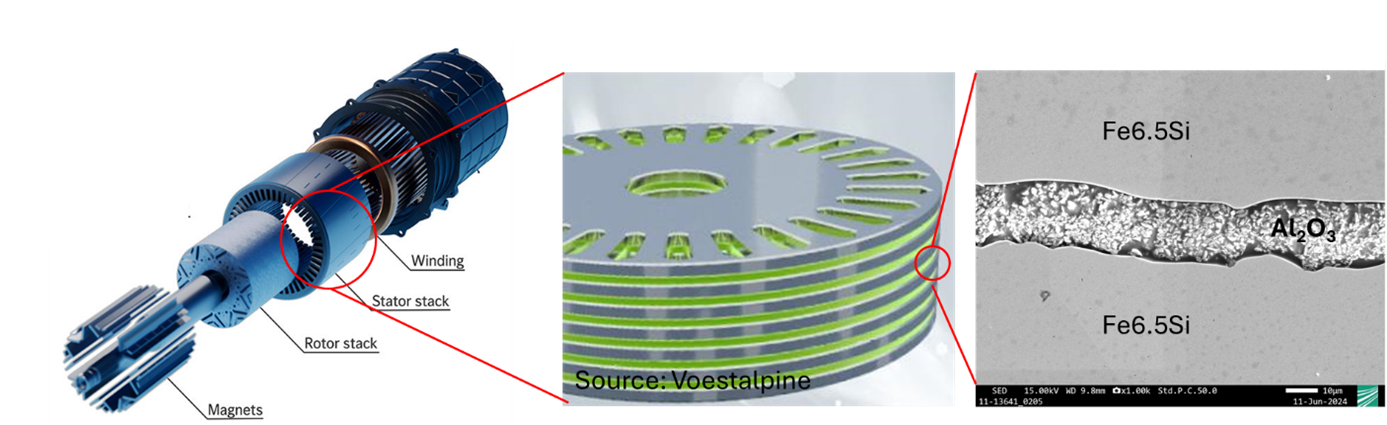

A significant portion of the losses in electric drives occur in the soft magnetic stator stack. These losses can be minimised by reducing the sheet thickness to 100 µm and additionally using highly efficient material systems such as Fe6.5Si. In contrast to conventional manufacturing processes (stamping), these materials can be processed into individual sheets using screen printing. The manufacturing process for the packages is simplified by integrating the necessary insulation layer between the individual sheets into the screen printing process. In this case, the additive screen printing process utilises its capabilities to:

- Produce multi-material systems using sintering technology (in this case Fe6.5Si – Al2O3)

- Efficiently manufacture flat components with diameters of up to 220 mm

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM