Technology and analytical facilities

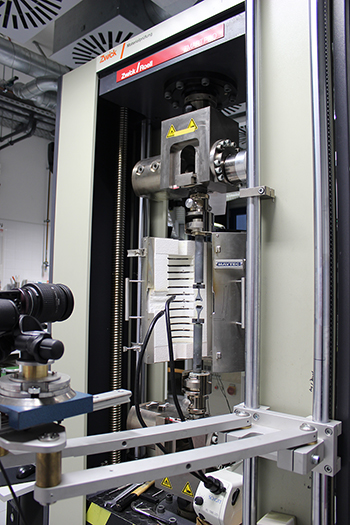

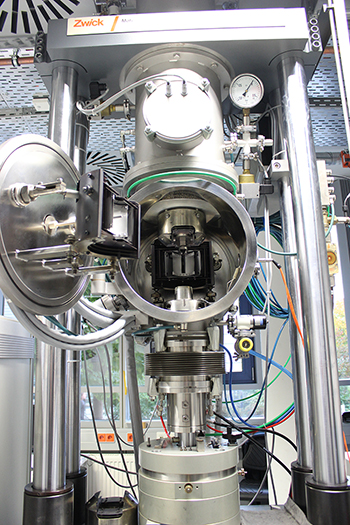

Universal testing machine Zwick 1476 (year of manufacture 1993, modernization 2010)

- Tensile testing at room temperature (DIN EN ISO 6892-1)

- Tensile testing up to 1000 °C in air (DIN EN ISO 6892-2)

- Individual testing with freely programmable process (load, elongation, temperature)

- 4 load cells for maximal forces of 200 N, 1 kN, 10 kN and 100 kN (annually calibrated)

- Measurement of elongation with videoextensometer (Limess, RtSS, annually calibrated) or traverse (annually calibrated, with deformation correction)

- Analysis of local deformations with software Vic 2D

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM