Process integrated component marking: point by point to better traceability

Companies need better transparency in their supply chain to ensure optimum quality and to react more quickly to events such as product counterfeiting. Leibniz Institute IPF, Fraunhofer IFAM, and the SKZ Plastics Center have thus set up the PICtor project to research a sustainable solution for individual and robust component marking at the single part level.

The traceability of products has a high value for many companies. For example, the damage caused by counterfeit products in Germany alone amounts to around 50 billion euros per year. Traceability also contributes to the consistent implementation of circular economy. According to calculations by the European Commission, companies could generate up to eight percent more revenue per year and make significant savings in greenhouse gases. Targeted traceability of data to manufacturers and their production information also allows defective products to be more specifically assigned to process parameters and material properties, and also saves billions of euros in costs due to necessary product recalls.

Applying markings already during injection molding

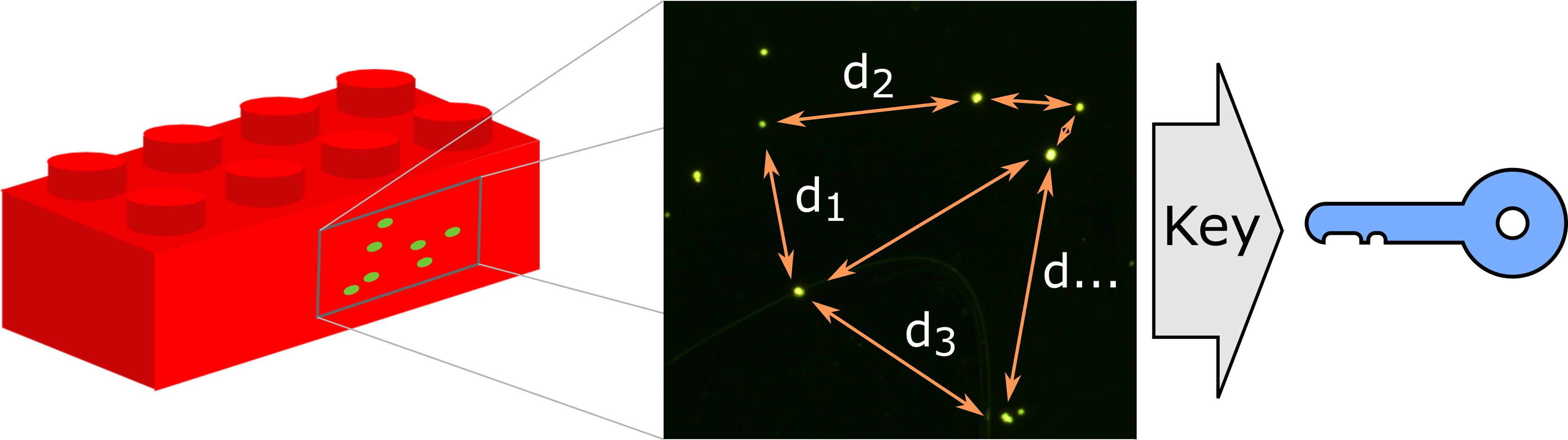

The consortium of three renowned research institutes intends to address this demand from industry over the next two years with an innovative solution concept. The central idea is to apply markings consisting of randomly distributed microparticles to the surfaces of the molded parts during injection molding, which allows for a controlled individualization a specific part by the respective random structures. After molding, the components are registered and ideally recognized at any time by re-reading the marking. For this purpose, fluorescent microparticles are used to enable the markings to be read, for example, by means of simple cell phone cameras. The desired method can thus be combined directly with commercially available detection systems.

Integration of the marker application into the injection molding process

A central element of the PICtor project is the integration of the marker application into the injection molding process. For this purpose, the particles are applied to the mold surface in the form of an ink and transferred to the component by injecting the plastic melt. This form of process-integrated application offers several advantages. Subsequent process steps for component marking are eliminated and counterfeiting by third parties or subsequent manipulation are prevented. It is easy to apply the markings to geometrically complex components and structured surfaces and the particles are embedded in surfaces in such a way that adhesion and abrasion resistance are increased. Suitable application techniques (spray coating, pad printing) are therefore being tested within the project in order to produce particle structures that are as random as possible while maintaining consistent quality. To ensure the long-term stability of the markings and avoid particle losses, the particles are further modified with customized adhesion promoters. These react directly with the plastic melt during the injection molding cycle, forming covalent bonds between the particles and the plastic and thus improving adhesion.

The Leibniz Institute IPF uses its existing expertise in the fields of surface and interfacial chemistry to modify fluorescent microparticles with the aid of macromolecular adhesion promoters and formulate them into processable dispersions. The integration of the marker application into the ongoing injection molding process and the process optimization are carried out with the help of the process engineering expertise of SKZ. Fraunhofer IFAM digitizes the markers and performs the aging tests.

Background information

The PICtor project started on August 1, 2021. Interested companies are cordially invited to participate free of charge in the project-accompanying committee of the PICtor research project (IGF no. 21964 BG), to help shape the investigations in this research project and to find out about the current results. The project is funded by the German Federal Ministry for Economic Affairs and Energy via the AiF as part of the program for the promotion of joint industrial research (IGF) of the Research Association Plastics Center on the basis of a resolution of the German Bundestag.

Project partner

About the SKZ

As Europe's largest plastics institute, SKZ has been providing practical solutions for the plastics industry along the entire value chain for 61 years. The SKZ is a member of the Zuse Association. This is an association of independent, industry-related research institutes which pursue the goal of improving the performance and competitiveness of industry, in particular small and medium-sized enterprises, through innovation and networking.

About Fraunhofer IFAM

Fraunhofer IFAM is one of the most important independent research institutes in Europe in the fields of "Adhesive Bonding Technology and Surfaces" and "Shaping and Functional Materials". The focus at all six institute locations is on research and development work with the aim of providing industrial users with reliable and application-oriented solutions.

About the Leibniz Institute IPF

The major challenges in energy, mobility, health, sustainability and communication require new technologies and materials. Polymers offer unique opportunities to tailor materials and launch innovative technologies. At the IPF, researchers from various disciplines are collaborating to exploit this fascinating potential. As a member of the Leibniz Association, the institute is dedicated to application-oriented basic research and is strongly networked at the Dresden site, nationally and internationally.

Contact:

SKZ - KFE gGmbH: Anika Fuhrmann, phone +49 931 4104-244, e-mail:

a.fuhrmann@skz.de

Fraunhofer IFAM: Dr. Martin Wiesing, phone +49 421 2246-652, e-mail:

martin.wiesing@ifam.fraunhofer.de

Leibniz Institute IPF: Dr. Jürgen Nagel, phone +49 351 4658-399, e-mail:

nagel@ipfdd.de

Last modified:

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM