Real-Time Measuring Method Extends Lifespan and Enhances Safety of Batteries

An innovative measurement method enables optimized battery management in electric vehicles, helping to make them safer and extend their lifespans. Impedance spectroscopy from the Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM analyzes detailed measurement data on the battery’s state in real time during operation. This means batteries can also be used for safety-critical applications.

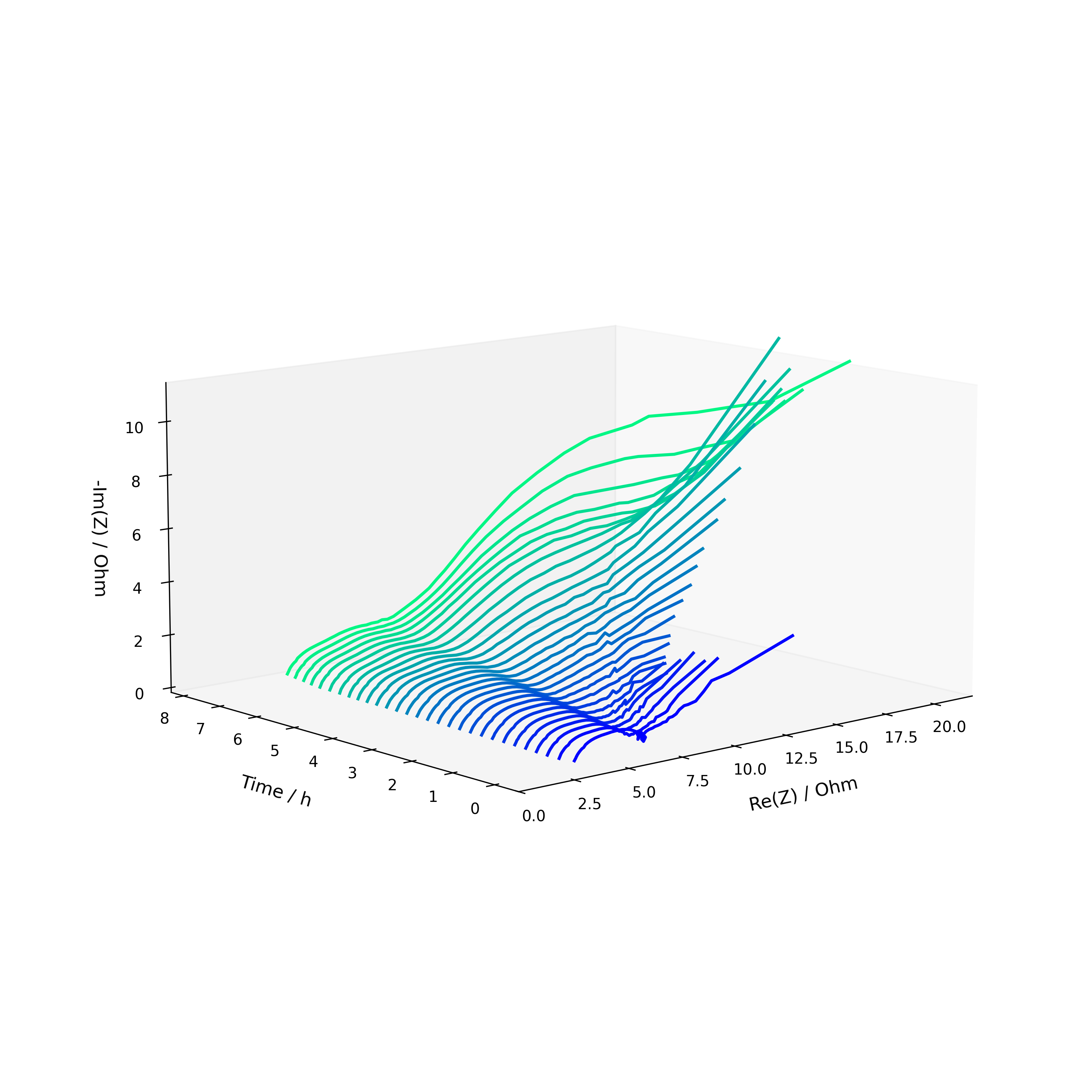

Powerful, safe batteries are a key component in the success of electric mobility. This makes measuring a battery’s capacity and state a crucial factor. The most informative method of doing this is impedance spectroscopy. Impedance itself cannot be measured directly; instead, it is calculated from the relationship between current and voltage. Impedance provides information on the battery’s state of charge (SoC) and permits conclusions regarding its state of health (SoH, i.e., the condition inside the battery, where the cathode, anode and electrolyte are located) or its safety status.

Collecting all the necessary data requires time-consuming measurements and analytical methods. On top of that, measuring impedance has only been possible in a resting state so far. It can typically take as much as 20 minutes before the data needed to characterize the battery is ready and available.

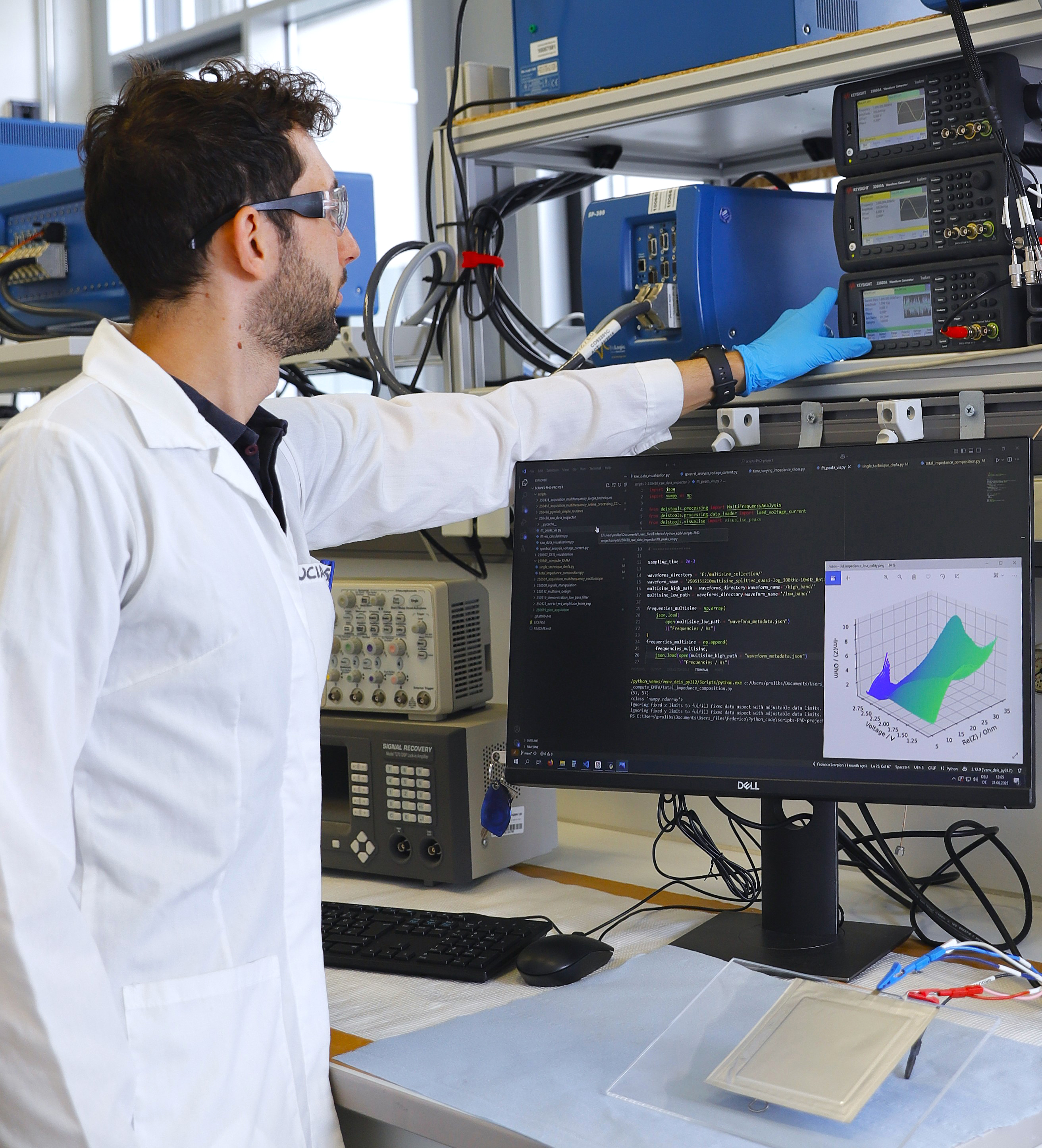

Researchers from Fraunhofer IFAM further developed this method under the leadership of Fabio La Mantia. Now, for the first time, dynamic impedance spectroscopy makes it possible to calculate measurements regarding the battery’s status during live operation and make them available in real time. The information obtained in this way encompasses much more than simple data about the charge capacity or remaining operating time. It provides a detailed, accurate and in-depth picture of what is going on inside the battery. This also makes it possible to predict the battery cell’s potential lifespan individually.

While existing battery charge status displays — which are incorporated into the vehicle electronics in electric cars, for example — do also take measurements on an ongoing basis during use, they offer less information, are much slower to respond and are not as accurate.

“First, dynamic impedance spectroscopy opens up new possibilities for optimizing battery management, thereby extending the batteries’ lifespan. It also paves the way for these batteries to be used in safety-critical applications,” explains Hermann Pleteit, who heads up the project.

High-resolution measurement method and direct analysis

In this innovative method, the discharging or charging current is overlaid by a multi-frequency test signal. The different frequencies make it possible to draw conclusions regarding the status of certain components or processes inside the battery. The response signal from the current and voltage is measured up to one million times a second. All of the data from the high-resolution measurement method flows into a data processing system that is running at the same time. A software program uses this information to calculate the evolution of the impedance values and then make inferences concerning the state of the relevant battery cell.

To obtain results in real time in spite of the vast volume of data generated by the high-resolution measurements, the Fraunhofer researchers devised another clever trick. “We developed algorithms that significantly reduce the volume of data before the analysis without dropping relevant information,” Pleteit says. In line with these advances, real-time control of all aspects of the battery’s state through impedance spectroscopy offers significant advantages.

Quickly powering down overheated cells

Battery management systems can use the impedance data to immediately register when a cell becomes locally overheated while driving, for example. Then they simply turn that cell off or reduce the power. This eliminates the need for conventional temperature sensors, which are placed on the outside of the battery cell , thus registering thermal issues with a delay. By that time, it is often too late to prevent the cell from being damaged.

There are also advantages to EV chargers. For example, this technology could be used to decide between extra-fast charging and charging that is slower but also reduces battery wear. During a brief pause at a rest stop, the battery management system charges the battery quickly while also ensuring that there are no dangerous temperature spikes and the internal components are not unduly stressed. If the vehicle is plugged into a charger for several hours, the management system charges the battery slowly to reduce wear and extend its lifespan.

Application for renewable energy and aviation

Providers of renewable energies such as wind power or photovoltaics, who need to compensate for fluctuations in electricity production with energy storage, are provided with stable battery module systems that can be controlled at all times thanks to Fraunhofer technology.

Real-time monitoring of the battery state will even unlock the possibility of use in safety-critical scenarios going forward. “These kinds of systems could be used in eco-friendly electric aircraft, for example. This market is in its infancy right now. And the shipping industry is also signaling interest in the technology,” Pleteit says. The Fraunhofer-Gesellschaft, headquartered in Germany, is one of the world’s leading organizations for applied research. It plays a major role in innovation by prioritizing research on cutting-edge technologies and the transfer of results to industry to strengthen Germany’s industrial base and for the benefit of society as a whole. Founded in 1949, the Fraunhofer-Gesellschaft currently operates 75 institutes and research units throughout Germany. Its nearly 32,000 employees, predominantly scientists and engineers, work with an annual business volume of 3.6 billion euros; 3.1 billion euros of this stems from contract research.

Impedance spectroscopy is not only suitable for the lithium-ion batteries that are commonly found today, either. This method can also be applied to solid-state, sodium-ion or lithium-sulfur batteries — or any other future technology.

Pictures and PDF for Download

Last modified:

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM