Functional integration through printing technologies

The »Functional Printing« technology platform includes digital and mask-based printing technologies, with which components can be functionalised specifically and precisely at the required component points. Sensors or electronic components can thus be integrated into existing products and give the component additional or completely new properties and functions. Fraunhofer IFAM offers all the important printing processes and has in-depth expertise in materials. If printable inks or pastes are required for sensory applications, for example, which are not commercially available, these can be developed at Fraunhofer IFAM.

Inks and pastes: the key to functional integration

Functional printing uses printing processes that are familiar from colour printing or for applying adhesives/solder pastes, but also special printing processes. The printed materials, so-called inks and pastes, are the key to functional integration: they contain the particles that lead to the desired functions such as electrical conductivity or sensory properties. By choosing a suitable printing process and material, structure sizes ranging from a few micrometres to large areas of several metres can be realised. Functional printing is not limited to 2D substrates; robots and multi-axis systems can also be used to print complex 3D surfaces or flexible and stretchable films and textiles.

Functional Printing: Material-saving and environmentally friendly process

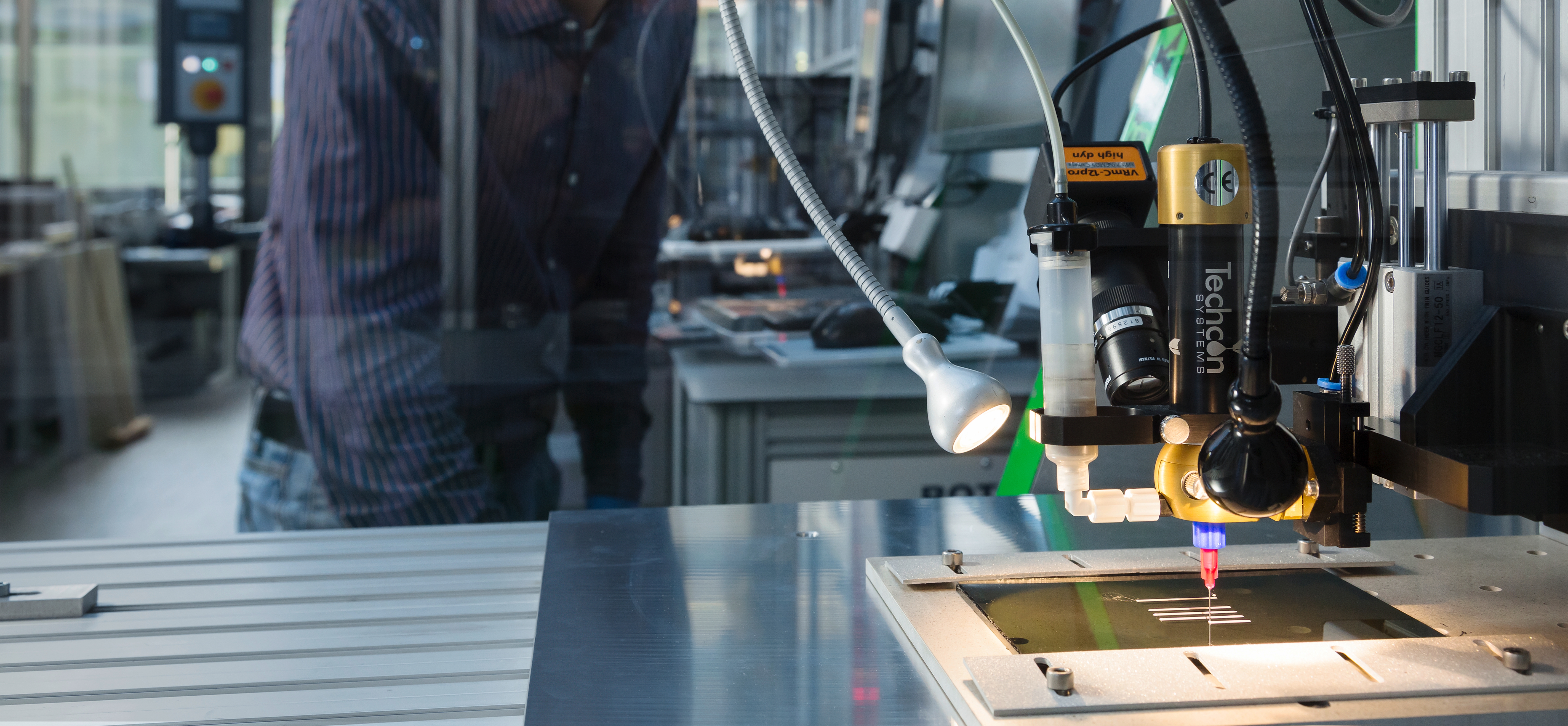

At the centre of Functional Printing technology is the material that enables the properties that are desired on the component. This material is printed either with a mask-based process such as screen printing or pad printing or a digital process such as aerosol jet printing, ink jet printing or dispensing. In contrast to lithography processes, the functional material is only placed exactly where it is needed in the application. A subsequent curing step, which takes place via temperature, UV, laser or flash light, leads to the desired properties of the applied material. All technologies have in common that they save material and can be environmentally friendly alternatives to comparable manufacturing processes.

Wide range of applications

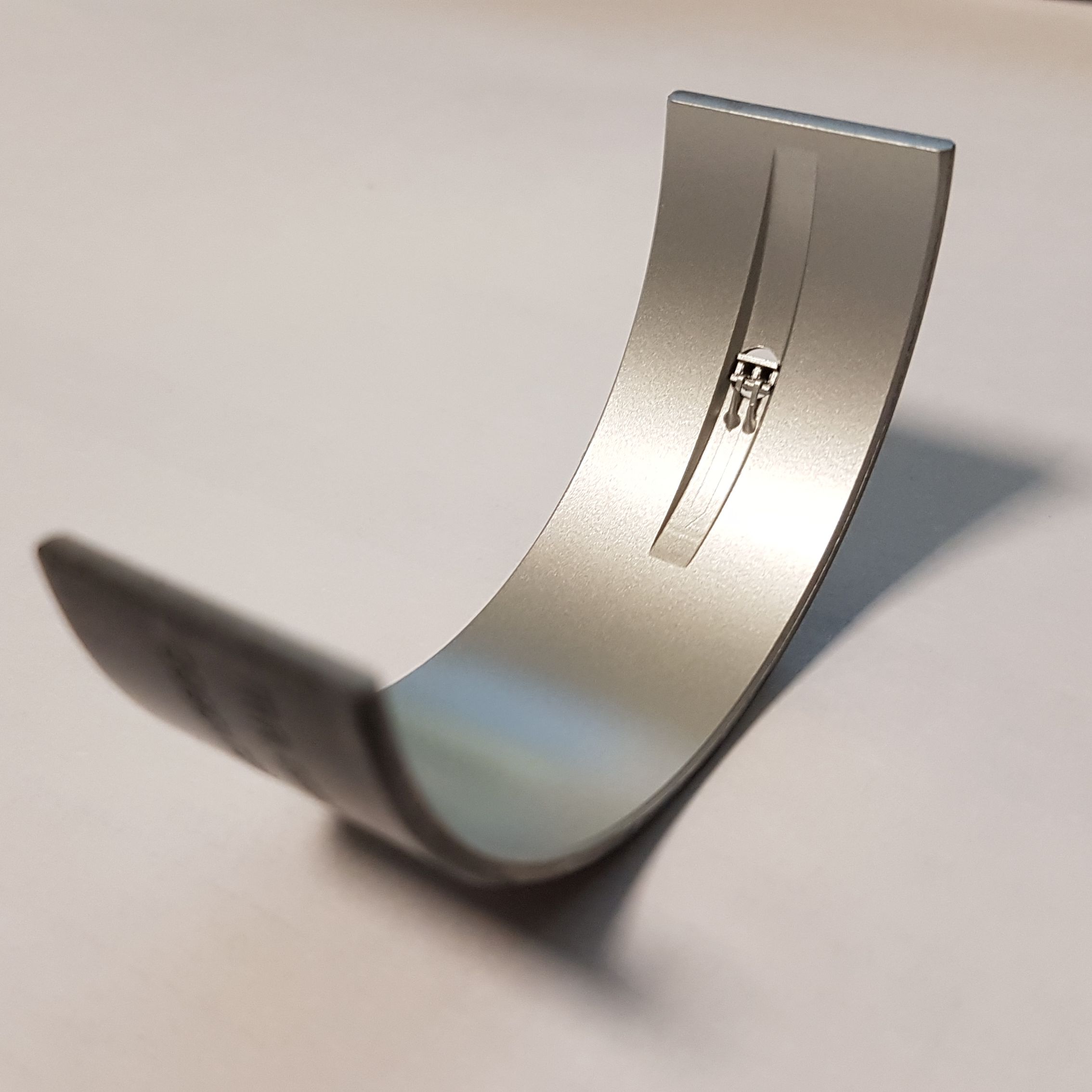

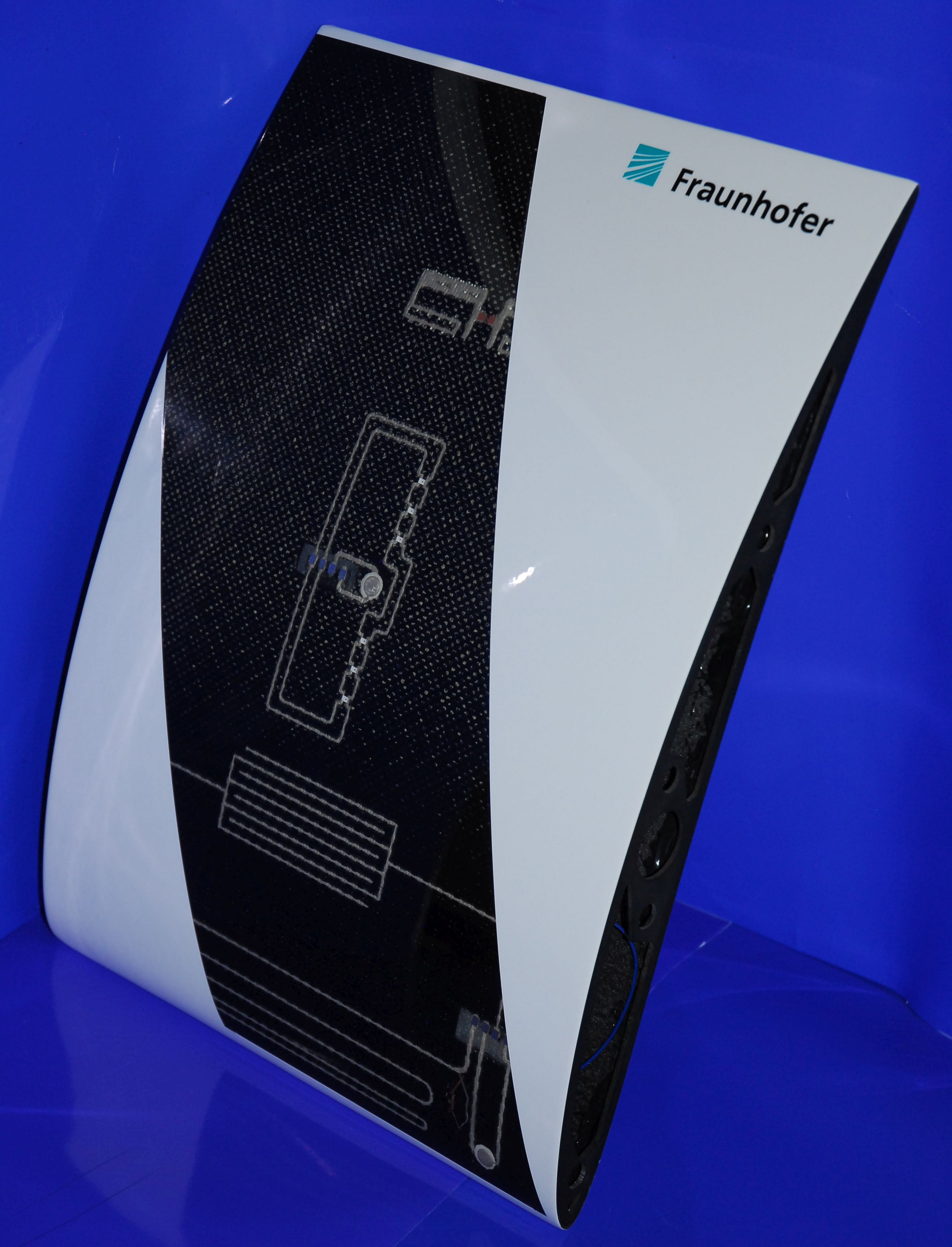

In addition to printing electrical conductors, a range of sensors can be applied directly at Fraunhofer IFAM. Examples of printed sensors are strain gauges, temperature sensors (resistive Pt100, Pt1000, thermocouples type K, J, T), capacitive sensors for detecting e.g. moisture or contact, vibration or impact and many other sensors. Active elements such as actuators and heaters (resistive e.g. PTC) can also be printed.

Functional printing makes it possible to adapt the sensor to the specific conditions of the component and to print directly onto the component surface. In addition to a high degree of automation, this also has the advantage that response times can be significantly reduced. Component areas with complex surfaces, where film-based sensors reach their limits, can also be printed. Functionalisation is not limited to the surface of the component; during additive manufacturing, conductive tracks or sensors can also be inserted into the interior of the components. Glass fibre or carbon fabrics, which serve as semi-finished products for the production of fibre-reinforced plastics, can also be provided with sensors, which are located inside the components after production. These approaches offer completely new design and layout possibilities and can significantly increase the functional density. Components do not have to be designed from scratch; the technology also allows existing components to be enhanced with functionalities and thus create added value.

Analytical technology and the printable materials are commercially available and allow rapid implementation in series production. If necessary, Fraunhofer IFAM modifies these materials and processes for specific customer requirements. Environmentally friendly materials, e.g. water-based, and robust printing processes offer the possibility of production in Germany with small runs and outside clean rooms.

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM