Highly stressed electronics, e.g. control systems for electric drives or smart controllers for water supply, are typically coated with a varnish or potting compound to protect them from moisture and other environmental influences. In the event of a defect, this protective coating stands in the way of repairing or unraveling the components, creating a typical conflict of goals between the longevity and recyclability of an electronic component. However, the reuse of electronic assemblies in particular is a core element of the circular economy called for in the 'European Green Economy Deal'.

Currently only manual decoating of electronic components possible

According to the current state of the art, there are no approaches for repairing such assemblies that go beyond manually removing the protective coating. There are also significant restrictions on recycling, depending on the encapsulation or coating material used, which is why thermal recycling is the most common option. An environmentally friendly and flexibly applicable alternative is provided by laser ablation processes, which have already proven their worth in various industrial fields of application. However, complete and at the same time gentle laser ablation is not yet possible in view of the 3D contours, high manufacturing tolerances and hybrid material combinations that occur in encapsulated electronic components.

Goal: New and automatable concepts for the environmentally friendly recycling and repair of electronic components

The aim of the Rapid-KI project is to develop control concepts to overcome the aforementioned limitations of laser ablation processes for the local decoating of encapsulated or protective-coated electronic components. For this purpose, sensor data are collected, evaluated by means of AI and used for a highly dynamic real-time control of the laser processes to enable innovative recycling and repair concepts. The high flexibility and scalability of the laser technology also allows subsequent transferability of the development to a wide range of application fields, e.g. decoating in the wind energy sector, ship, rail, and aircraft construction, as well as repair applications in the field of e-mobility.

Fraunhofer IFAM is working on the following sub-areas in the project:

- Selection and characterization of potting compounds and coating systems

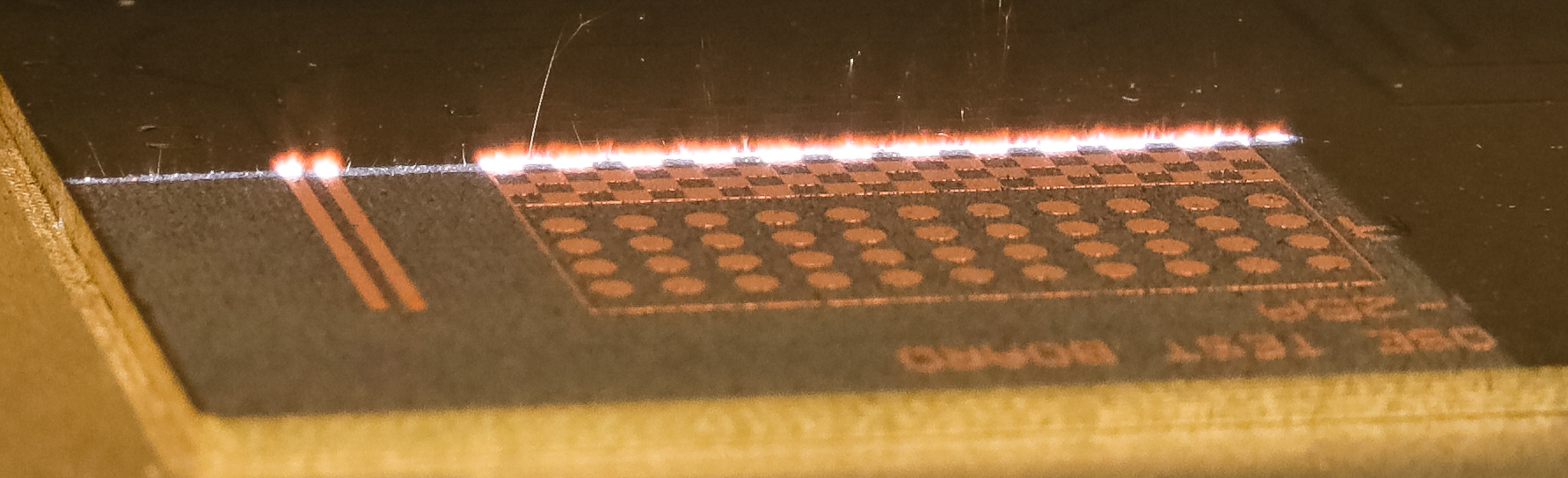

- Influence of laser radiation on coatings and development of suitable (paint) ablation parameters

- Design of a dynamic control loop for the control of the laser ablation system with the integration of sensor modules

About the project:

Project partners:

- Fraunhofer IFAM (Coordinator)

- Fraunhofer EMI

- Fraunhofer IDMT

- Fraunhofer ILT

Project duration:

March 2022 - February 2025

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM