Quality assurance using innovative analysis methods

In industrial manufacturing, quality assurance plays a crucial role in wet chemical processes. A fast and precise analysis method is essential to ensure the efficiency and longevity of the products. Simultaneous multi-element analysis using laser-induced plasma spectroscopy (LIBS) and impedance spectroscopy offer new possibilities for monitoring metal pretreatment baths, especially in non-electrolytic copper deposition.

Importance of conversion coatings

Conversion coatings are essential for the production of durable adhesive bonds as well as for coatings on aluminum. Only correctly executed processes can meet the requirements for corrosion protection and adhesion. Quality assurance of the process baths for conversion coatings is the decisive factor in ensuring that subsequent processes run successfully. Precise control of the bath composition is necessary to avoid contamination and ensure the desired chemical properties.

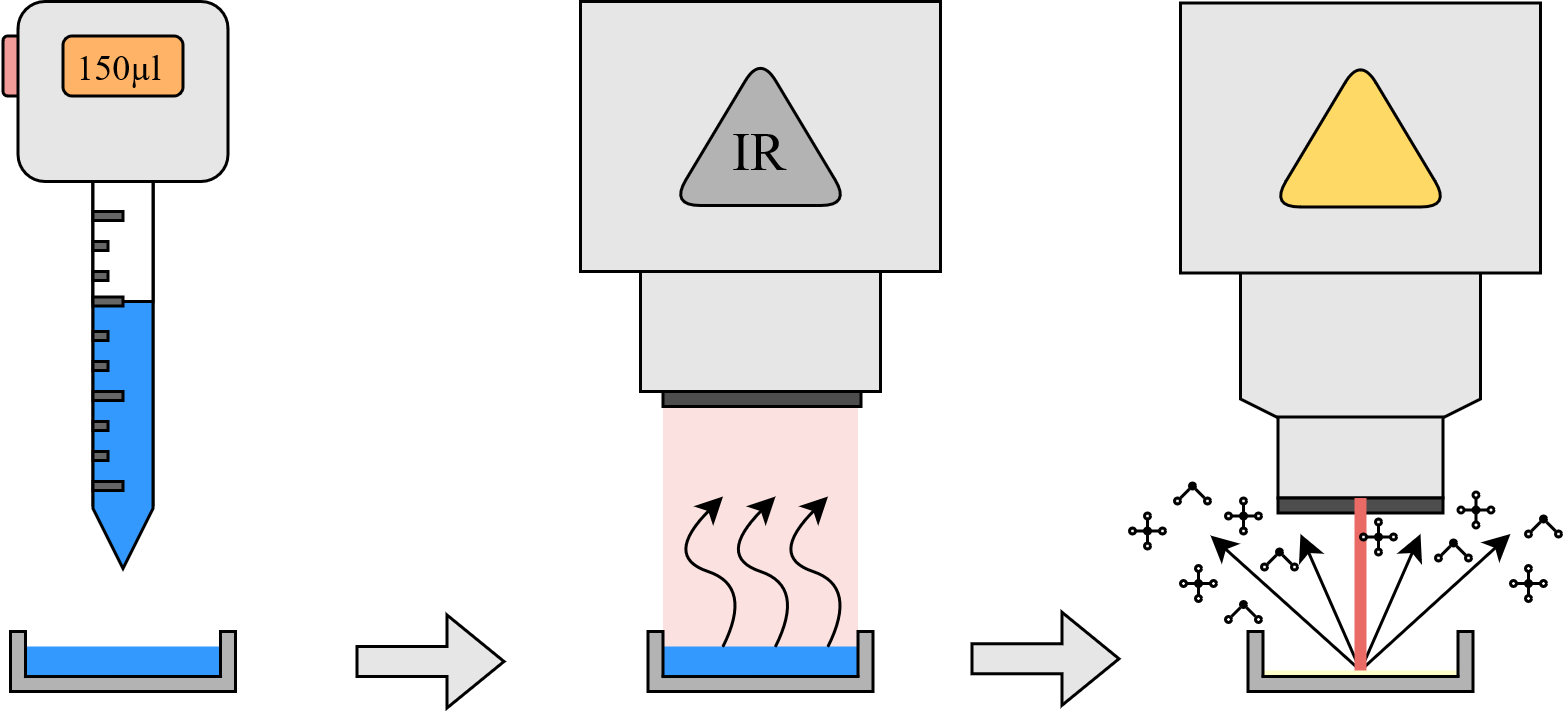

How laser-induced plasma spectroscopy (LIBS) works

LIBS technology enables continuous monitoring of the chemical composition of bath solutions in real time. Therefore, a pulsed laser beam is focused on the sample surface, generating a plasma. This plasma emits a characteristic light spectrum which is analyzed using a spectrometer. This method allows simultaneous detection of multiple elements and provides immediate feedback on the bath composition.

Advantages of LIBS technology:

- Real-time monitoring: Deviations in chemical composition are detected immediately, enabling a quick response.

- Multi-element analysis: The simultaneous detection of multiple elements reduces the time required for analysis and increases efficiency.

- Flexibility: Adaptation to a variety of different applications and measurement tasks through specific calibration for a wide range of elements or element combinations.

The LIBS method has proven to be reliable, especially for determining Ti concentrations in process baths, which underscores its suitability for quality control in industrial applications.

Monitoring copper deposition with impedance spectroscopy

Another innovative method for monitoring electroless copper deposition is impedance spectroscopy. A measuring system with a capacitive sensor element has been developed that offers simple operation with a graphical user interface and a clear structure. The sensor element enables impedance measurement during metal deposition and provides valuable information about the start-up behavior of the copper electrolyte on laser-activated components.

Advantages of impedance spectroscopy:

- Easy operation: Intuitive graphical user interface enables uncomplicated handling.

- Optimization of the deposition process: Adaptation to specific substrate materials and bath conditions leads to better results.

- Extended quality assurance: Provides an additional method for monitoring metallization that goes beyond standard analyses.

The concept comprises a PCB-based design with reusable stainless steel electrodes and an integrated digital temperature sensor. This enables precise measurement of the bath temperature and contributes to the accuracy of the measurements.

Key technologies for increasing efficiency in quality assurance

The combination of laser-induced plasma spectroscopy and impedance spectroscopy is a robust solution for monitoring wet chemical baths. These technologies not only help to ensure product quality, but also enable rapid intervention in the event of irregularities in the chemical composition. The implementation of these analysis methods can therefore contribute significantly to increasing efficiency and reducing costs in production.

These technologies offer the opportunity to optimize your processes and ensure the quality of your products. Continuous monitoring of process baths using LIBS and impedance spectroscopy is the key to successful and sustainable production.

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM