Sealants are indispensable in aircraft construction and other areas of the transport sector. They provide protection against corrosion, serve as joining technology, and contribute to improving aerodynamic properties. Reliable curing of the sealants is crucial for the quality and safety of the final components. However, sealant curing has only been tested on a random basis using standardized laboratory procedures – there is no direct, process-accompanying quality control.

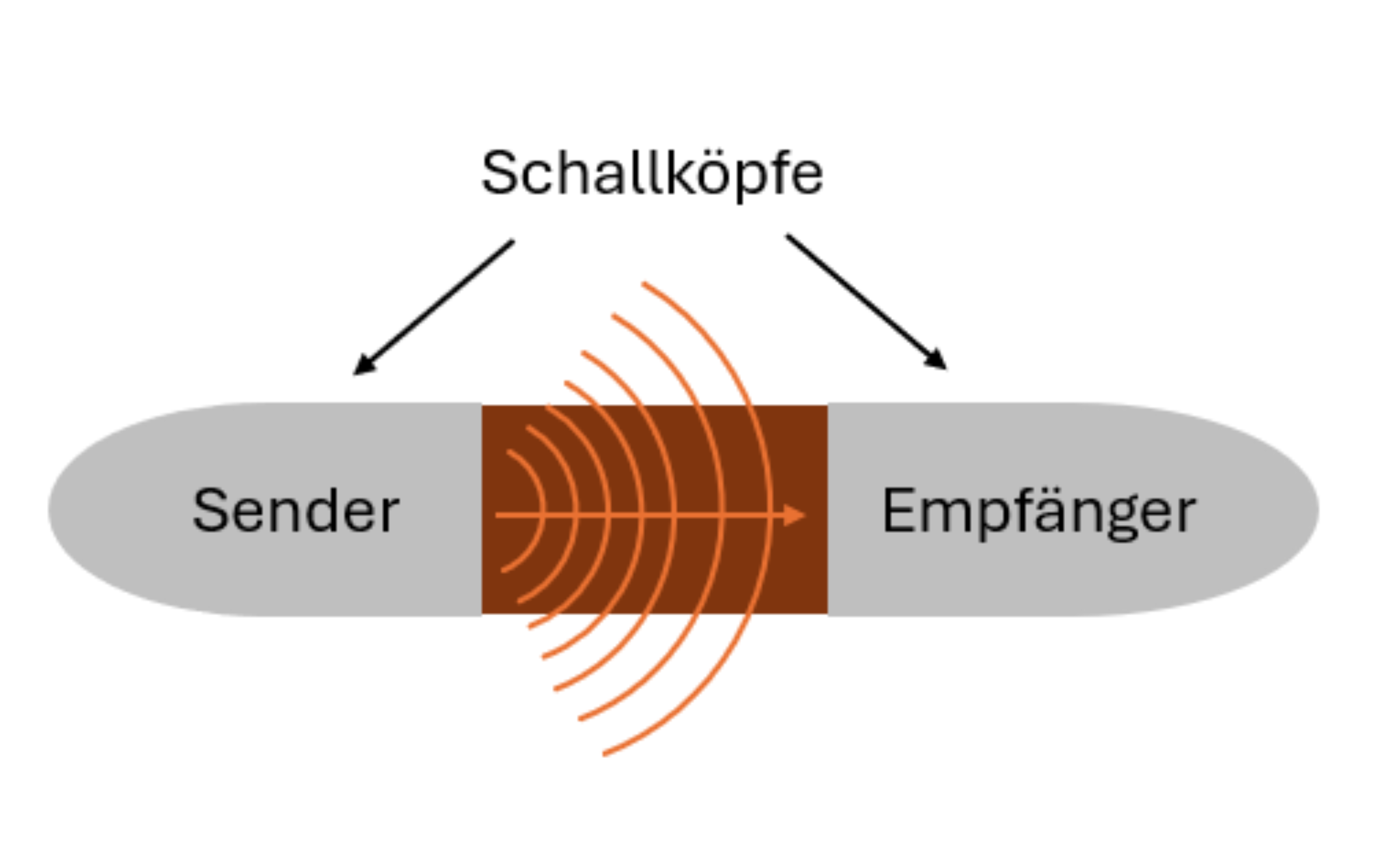

As part of the Lufo project “Piranha,” an existing ultrasonic system has been further developed specifically for monitoring the curing bahaviour of sealants. This new method allows tracking of the curing process in real time immediately after its application. To this end, the sealant is applied into a measuring mold in which ultrasonic waves are transmitted through the material. Changes in the material properties during curing can thus be measured precisely and compared with real component conditions.

Measurements with two different sealants used in aviation show clear information about the sealant´s curing behaviour and confirm the high reproducibility of the process. Deviations from the expected curve can be detected at an early stage – an important advantage for identifying faulty curing directly in the process.

The advanced ultrasonic system thus represents a novel possibility for process-accompanying quality assurance. It is currently being implemented by Ultratest as a commercially available product for the aviation industry and its suppliers.

Further information (in german) can be found in the article »Process-accompanying assurance of sealant curing«. The article was published in adhäsion KLEBEN+ DICHTEN 69 (2025) Issue 6, pp. 44-46.

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM