Electrochemical recovery of critical raw materials from wastewater

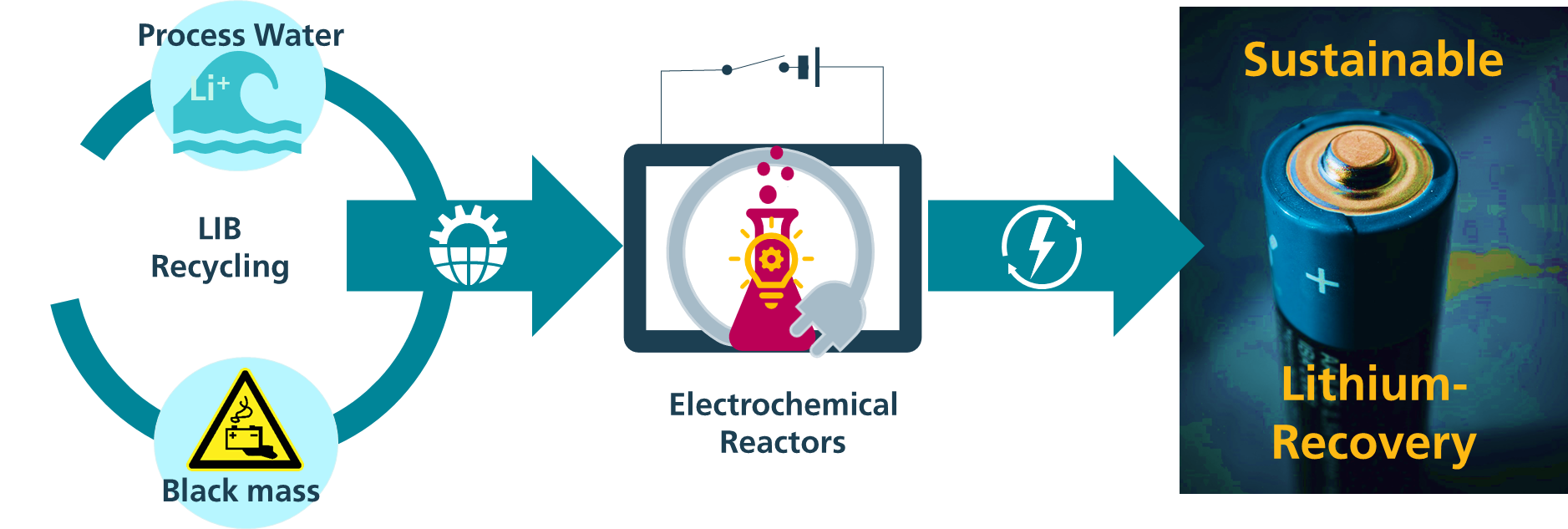

The efficient recovery of critical raw materials from batteries and production waste is a major challenge for the modern battery industry. In the MeGaBat project, we are developing a sustainable, cost-effective, and low-emission technology for the electrochemical recovery of lithium, cobalt, and other critical raw materials from aqueous sources (wastewater) to solid production waste. Our goal: to establish a flexible, scalable process that advances the circular economy in the battery industry and contributes new concepts for the further development of urban mining.

Urban mining: Sustainable critical raw material recovery from waste for the battery industry

Our electrochemical process is characterized by high selectivity for lithium (Li) and other valuable metals (such as cobalt or nickel), combined with low energy and water consumption. The process is designed to be suitable for different Li concentrations and to minimize the consumption of chemicals. We are thus closing an important gap between research and practical application in industry by enabling the efficient recovery of critical raw materials from aqueous waste – a solution that can significantly improve the recycling process for battery manufacturers and recyclers.

Optimization for battery recyclers: Higher yield, less waste

For battery manufacturers and recyclers who work with process-related wastewater, our process is the perfect complement to existing recycling processes. Even small residues of lithium and cobalt, which you would normally dispose of, can be recovered. This allows us to increase the yield of your recycling processes and help you uptake more critical raw materials.

The electrochemical process is developed with the aim of being scalable and flexible. We adapt our technology to the specific requirements of your production processes – whether it's the recovery of lithium from production waste or the treatment of wastewater from battery recycling. Our process offers you a sustainable and economical solution for efficiently recovering critical raw materials from various sources.

Collaboration for the future of battery production

We invite companies from the battery industry to provide us with valuable process water from their plants. These collaborations not only provide important input for the further development of our process, but also enable us to scale the technology to industrial standards and continuously improve it. Your support plays a key role in the successful completion of the MeGaBat project and in the realization of more environmentally friendly and resource-efficient battery production.

The MeGaBat project: A milestone in the circular economy

As part of the MeGaBat project, we are developing an electrochemical technology that selectively recovers not only lithium, but also cobalt, nickel, and other important critical raw materials from aqueous sources with a high degree of purity. The goal is to scale up the technology to an industrial level in order to enable emission-free, cost-effective, and sustainable production of these raw materials.

Through close cooperation with industry, we want to ensure that our process not only works in theory, but is also tested and validated in real production environments. In doing so, we attach great importance to the economic efficiency, environmental friendliness, and sustainability of the technology.

A future-proof process for the battery industry

The recovery of lithium and other critical raw materials from aqueous sources represents a decisive step toward a more sustainable circular economy and more resource-efficient battery production. By further developing and scaling the MeGaBat process, we are making an important contribution to the security of lithium supply in Europe and reducing dependence on critical raw materials. Close cooperation with companies in the battery industry enables us to validate and establish this technology on an industrial scale.

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM