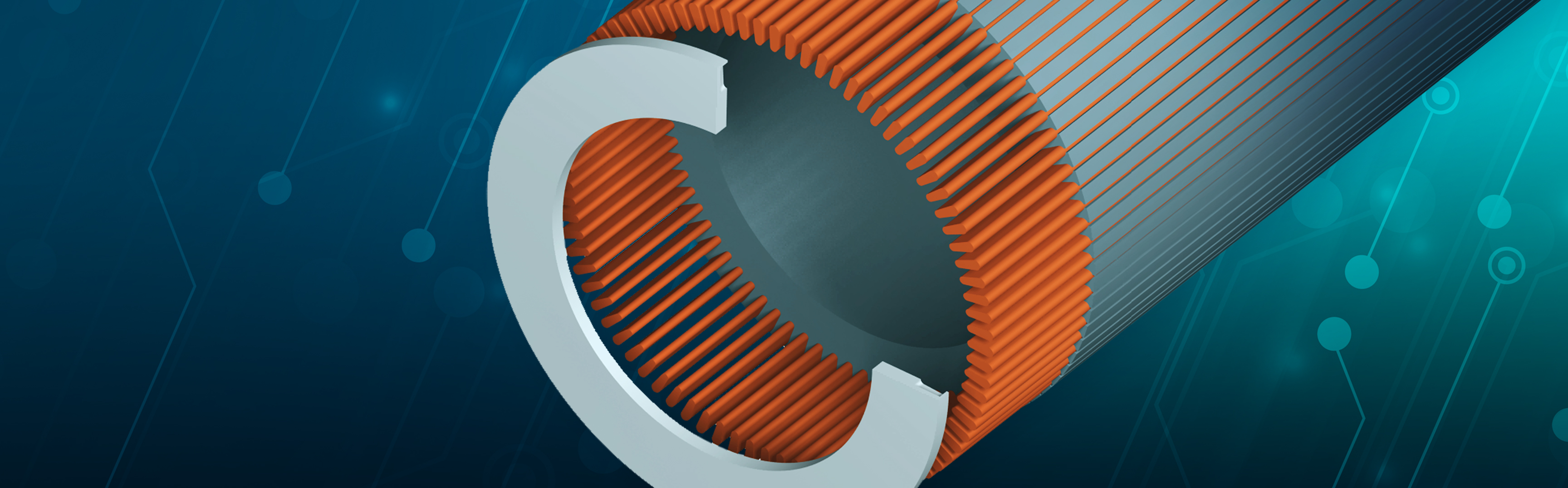

In the project "UltraHybRo", the experts of the area "Electric Drive Technology" at Fraunhofer IFAM are developing a joining process for the manufacture of squirrel cage rotors for induction machines together with the project partner mth Ultraschalltechnologie GmbH & Co. KG. They are pursuing a novel approach to increase the efficiency of induction machine over a wide operating range. This requires the development of a new concept for ultrasonic welding and research into the design and dimensioning of hybrid squirrel cage rotors. This will establish the ultrasonic welding process for joining aluminum end rings and copper rotor bars to enable the low-cost, reproducible manufacture of hybrid rotors. For this purpose, the hybrid rotors must be designed and configured in a manner suitable for production in order to make the advantages of the process as well as the principle-related advantages of the hybrid rotor usable in series production.

Increasing electrification in all areas of industry and mobility is creating new challenges in achieving the development goals and market needs of induction machine (IM). The focus is on increasing efficiency while reducing installation space requirements, lowering manufacturing, material and maintenance costs of efficient motors, and increasing manufacturing quality and process reliability to reduce scrap. Induction machines with squirrel cage rotors are characterized by their cost-effective, resource-saving and robust design and are therefore already widely used in industrial applications. However, IM typically achieve somewhat lower efficiencies and lower gravimetric and volumetric torque density when compared directly to permanent magnet synchronous machines (PMSM). To meet the demand for high-efficiency IM, the partners in the project "UltraHybRo" are pursuing the jointed hybrid rotor approach as a better alternative for both ethablished IM and PMSM in vehicle applications, as well as to meet regulatory efficiency requirements for industry machines (IE3 and IE4). The objective is to develop a joining process for the production of hybrid rotors for squirrel cage induction machines. Whereby the end rings are made of aluminum and the rotor bars of copper and are joined by ultrasonic welding.

The project "UltraHybRo" is funded by the Federal Ministry for Economic Affairs and Climate Action within the funding program "Zentrales Innovationsprogramm Mittelstand (ZIM)" (funding number KK5031418EW1).

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM