Automated solutions for series production: robot-based application technologies in operation

Adhesive tapes and adhesive films are utilized in a variety of industries and cover a wide range of different functions. These range from force transmission through gap compensation and sealing up to labeling.

Examples from practice

Automotive industry

- Structural adhesive bonding of car body components

- Fastening of trim strips

Rail vehicle construction

- Structural adhesive bonding of car body components

- Assembly and fastening of interior elements

Aviation and aerospace sector

- Connection of structural elements

- Corrosion protection and sealing material

Wind turbine construction

- Structural bonding of rotor blade halves, shells and spars

Civil engineering

- Sealing, insulating and fixing facade elements

Electronics production

- Insulation, heat dissipation or fixing sensitive components

Medical technology

- Skin-friendly, temporary or sterile adhesive bonding solutions

Depending on the application, both pressure-sensitive adhesive tapes and post-crosslinking adhesive films can be used. Due to their individual processing properties, these require highly specialized application systems for industrial use.

Increasing quality and productivity through automated application technologies

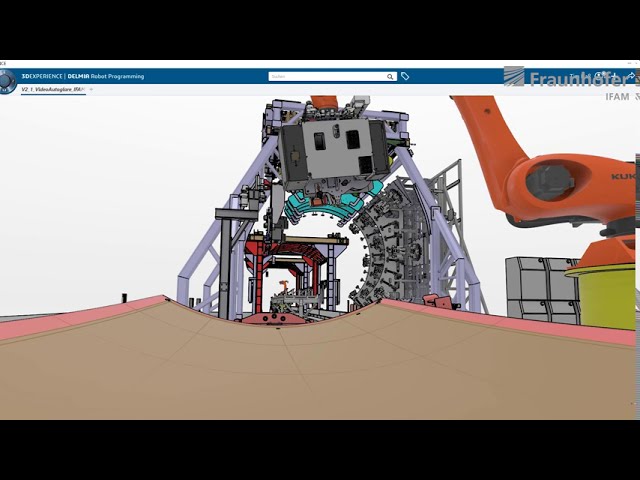

Automated applications are particularly crucial in series production at high cycle rates in order to ensure consistently high quality and process reliability. Fraunhofer IFAM in Stade develops customized, robot-assisted application systems for adhesive tapes and adhesive films as an R&D service provider – from the concept phase through prototype development up to integration into industrial production. The expertise is based on the combination of material, process and plant competence, whereby precise, reliable and at the same time economical application processes can be realized – even with complex 3D geometries and the highest requirements of aviation and aerospace industry.

Specially developed, modular robot-guided deposition heads not only enable high-precision deposition with tolerances in the sub-millimeter range, but also a high degree of flexibility with varying component geometries and complex deposition paths. Depending on the application, functions such as automatic cutting, liner removal, defined application pressure and thermal activation can be integrated to create good adhesion. Supplemented by AI-supported inline quality assurance and offline programming, this creates flexible, versatile production systems that can be quickly adapted to new products and geometries.

Fraunhofer IFAM thus offers industrial partners from aviation and aerospace, automotive and commercial vehicle, rail vehicle construction as well as wind turbine construction etc. individual solutions for increasing productivity, material efficiency and process stability.

Optimized material utilization through patch processes

In addition, the experts for Automation and Production Technology are developing pioneering patch processes in which adhesive films are precisely applied by robots in the form of several partial cuts. This technology enables optimum, cost-saving material utilization and opens up new degrees of freedom in the design of joining surfaces – especially for double curved surfaces. Stationary application systems are also available for large-area applications or continuous processes, which can be supplemented with optical inline measuring systems for quality assurance if required.

R&D partner for demanding bonding processes

Thanks to its many years of experience in the automation of adhesive bonding processes and its understanding of the requirements of safety-critical industries, Fraunhofer IFAM supports companies in the transfer of individual and cutting-edge adhesive bonding technologies into industrial practice. Whether feasibility studies, prototype development, process optimization or technology transfer – the researchers in Stade develop individual solutions when maximum precision, reliable quality and economical process design are required.

Automated adhesive tape and adhesive film application is a key technology for future-oriented joining processes, which are applied and continuously developed at Fraunhofer IFAM in a practice-oriented production environment. The experts from the “Joining and Assembly” department research and implement methods to automate adhesive bonding and joining processes precisely, reproducibly and efficiently. In Stade, specially developed, robot-assisted adhesive film applicators are available for this purpose, which enable the reliable deposition of a wide range of adhesive bonding systems – from pressure-sensitive adhesive tapes to post-curing epoxy adhesive films.

Fields of application are

- the automated deposition of adhesive films on complex 3D geometries,

- the force-fit and form-fit joining of fiber composite and metal structures on a 1:1 scale,

- the reliable confectioning of adhesive films for series production as well as

- the deposition of post-crosslinking glass fiber films for the production of fiber metal laminates (FML).

As a result, the Fraunhofer IFAM in Stade is making an important contribution to the industrial implementation of modern, automated adhesive bonding technologies for climate-relevant lightweight construction and efficient large-scale structure production.

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM