Biocide-free fouling protection and flow-optimized surfaces for the maritime industry

Functional coatings against biofouling and corrosion are an important part of the maritime industry. They protect ships and other maritime infrastructure in the harsh marine operational environment. Innovative coating technologies and materials are being researched at Fraunhofer IFAM to achieve effective and durable resistance to biofouling, corrosion, and mechanical abrasion, for example by underwater cleaning processes. This can reduce operating costs, extend service life, and improve environmental protection. The development of high-performance antifouling coatings is an important step towards a sustainable maritime industry, which in the future will focus, among other things, on the climate neutrality of ships and the expansion of renewable energies at sea.

Maritime research for the development of sustainable technologies

The maritime industry is closely linked to the global economy and plays an important role in providing goods and services. At the same time, the negative impact of ship operations on the environment is a serious factor. However, as environmental and sustainability requirements continue to increase, innovative technologies are in demand. From the development of more efficient propulsion systems to research into alternative energy sources such as wind, solar and wave power, there are many areas in which maritime research is being advanced. Coating technology represents a central factor here.

Avoiding biofouling: Innovative coatings for sustainable fouling protection in the marine industry

Protecting ship surfaces against fouling is of enormous importance to the maritime industry. Fouling on ship hulls significantly increases fuel consumption and the associated CO2 emissions. This has not only ecological but also economic disadvantages. New, high-performance coating technologies are therefore needed that are also more environmentally friendly and can withstand the special challenges of the maritime operating environment.

The requirements for these coatings are high: They must be cost-efficient and have a long service life. In addition, they must have low flow resistance, as this can significantly reduce fuel consumption and thus costs. According to scientific studies, pronounced fouling (biofouling) can increase the flow resistance of ships by more than 40%. The result is an increase in fuel consumption and thus greenhouse gas emissions, which can be as high as 40% even with a low level of biofilm fouling, and even up to 50% depending on the ship's speed. This not only increases the ecological footprint of the ships, or the goods transported, but also the operating costs for the shipping companies. The International Maritime Organization (IMO) puts the share of fuel costs in the total operating costs of a ship at 50-60%.

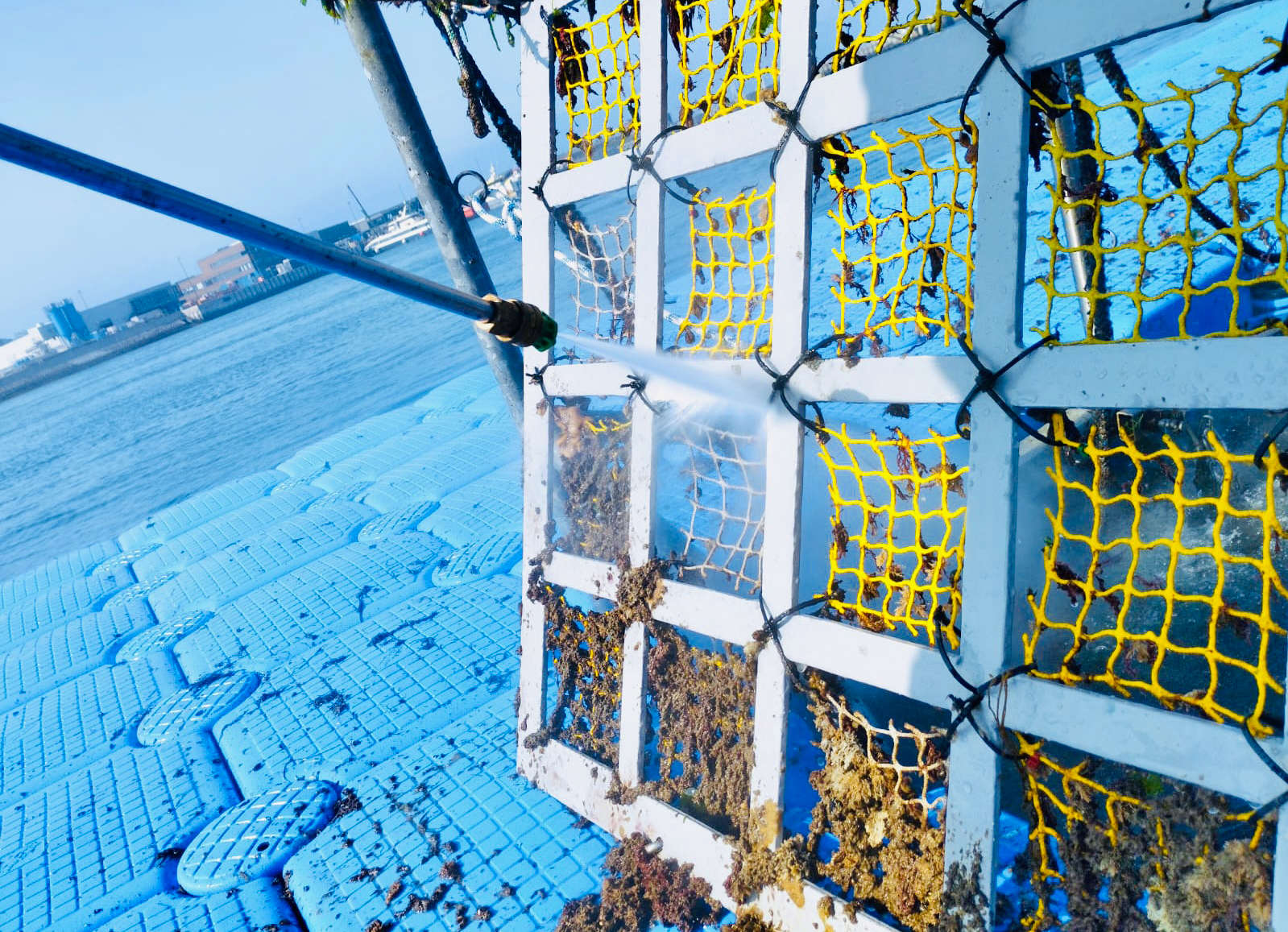

In addition, there are far-reaching regulatory requirements to be met for biofouling management on ships. Numerous countries and the IMO have enacted laws and regulations for ship operation with the aim of reducing emissions from ships (e.g., EEXI and CII). Therefore, coatings are required to meet current environmental and safety standards. Long-term high performance must be achieved with a minimum of environmental impact, e.g., by release of harmful substances. This is the predominant challenge that the scientists at Fraunhofer IFAM are tackling. They are researching innovative coatings which not only reduce the adhesion of biofouling, but also provide effective and durable resistance to mechanical abrasion and various cleaning processes, such as high-pressure water jetting or brush cleaning. The goal is to improve degradation protection in addition to fouling protection in order to ensure longer coating life. For this purpose, different materials and technologies are tested to find the best compromise between performance, durability, and environmental friendliness.

Biobased coatings based on renewable raw materials

A key objective of research and development work at the institute is therefore to reduce or even completely avoid the use of biocides. This is because many conventional coatings contain substances that are harmful to the marine ecosystem and can accumulate in the food chain and marine sediments. Efforts are therefore underway to increase the proportion of biodegradable coating ingredients in formulations, for example by using polyhydroxyalkanoates (PHAs) and polysaccharides.

Laboratory tests and field tests

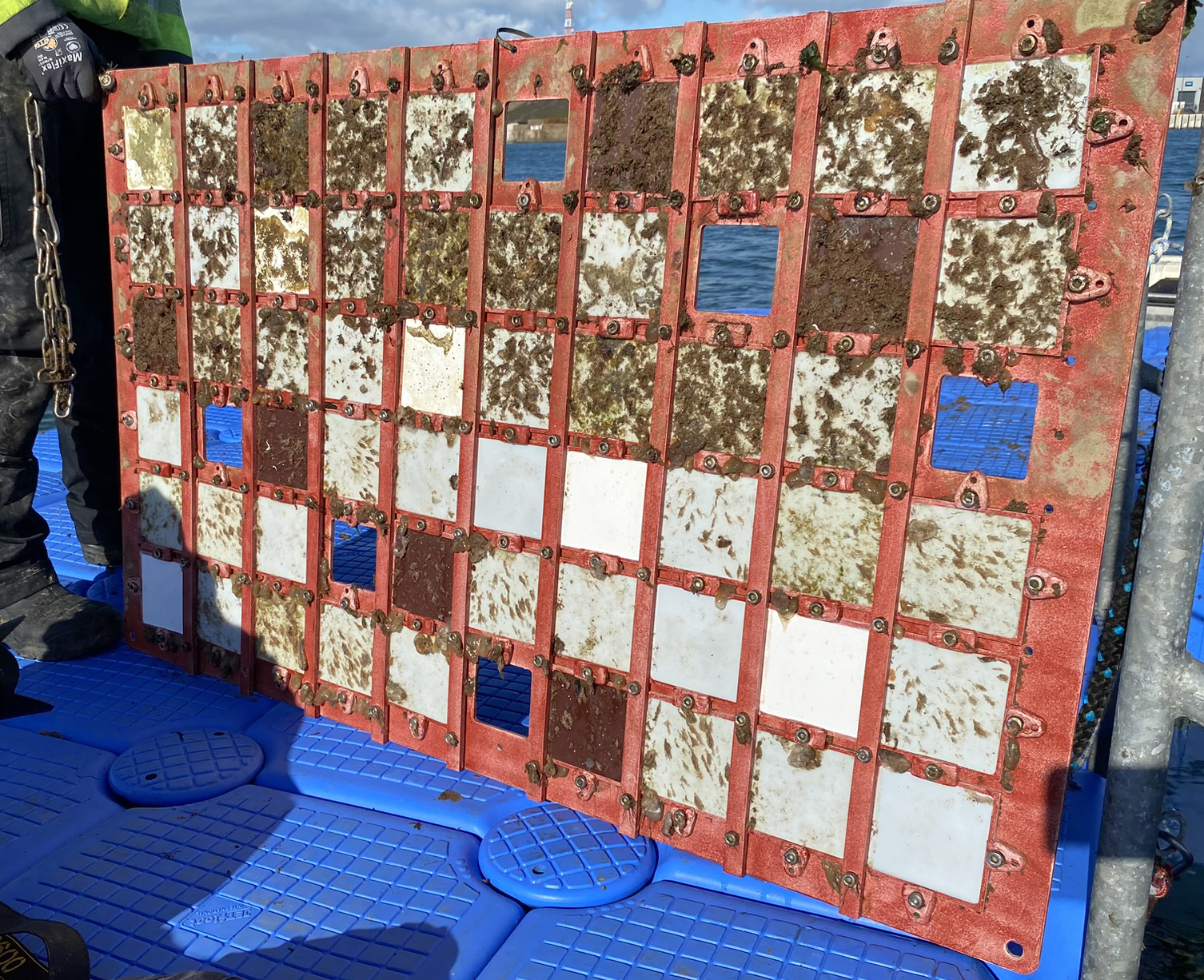

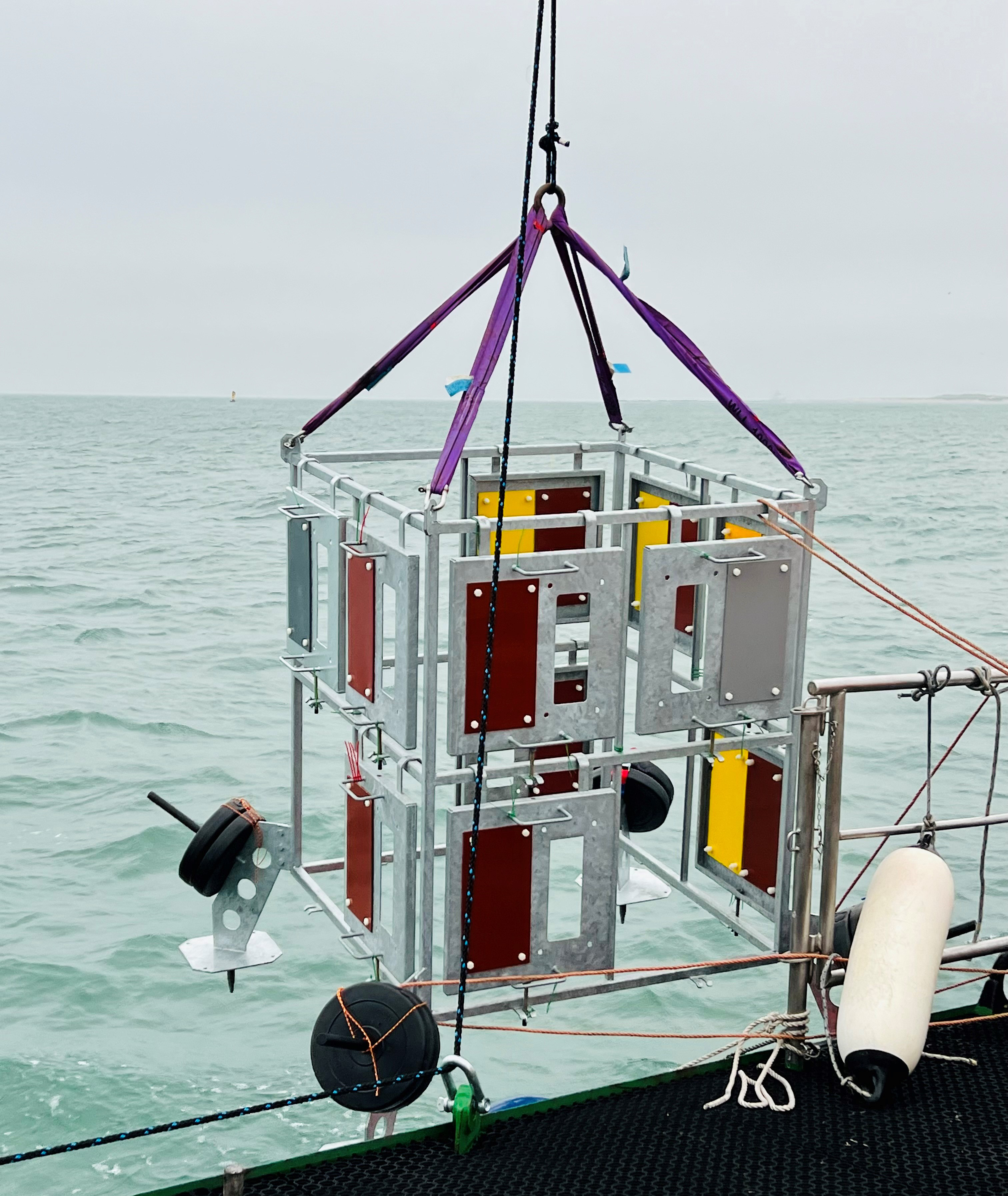

To test their effectiveness and durability, the development of new coatings requires extensive laboratory testing. This involves testing the coatings in standardized environments to ensure comparability between different formulations. Characterization includes parameters like adhesion, contact angle, hardness, scratch resistance, flexibility, corrosion resistance and resistance to salt water.

However, laboratory testing alone is not sufficient to evaluate the actual performance of coatings in real-world marine environments. It is therefore important to conduct additional field tests to assess the effectiveness and durability of new coating formulations.

In field tests, test patches are applied to the ship's hull or samples are immersed in static and dynamic fouling field test stations. The fouling is then documented and analyzed over a period of time according to standardized procedures (e.g., ASTM D 6990: (2020) Standard Practice for Evaluating Biofouling Resistance and Physical Performance of Marine Coating Systems). At its Bremen site, Fraunhofer IFAM has extensive laboratory test procedures, which are used in the development of new or optimized functional coatings. In addition, with the Test Center for Maritime Technologies on the offshore island Helgoland, the institute operates a large number of maritime test rigs for application-oriented testing of corrosion and anti-fouling coatings under real static or dynamic load cases.

Overall, anti-fouling remains one of the most important challenges in the maritime industry, especially in commercial shipping. Even more than today, it will be crucial in the future that coatings are both environmentally friendly and high performing. The challenges in coating development require close collaboration between research, industry and regulatory agencies to find the best possible solutions for global shipping. The development of anti-fouling coatings for ships is an important research focus in the business area Maritime Technologies. The scientists at Fraunhofer IFAM will be pleased to support you in the development of new coatings and in the further development of existing ones, and to offer you a customized, application-oriented testing scenario for your products.

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM