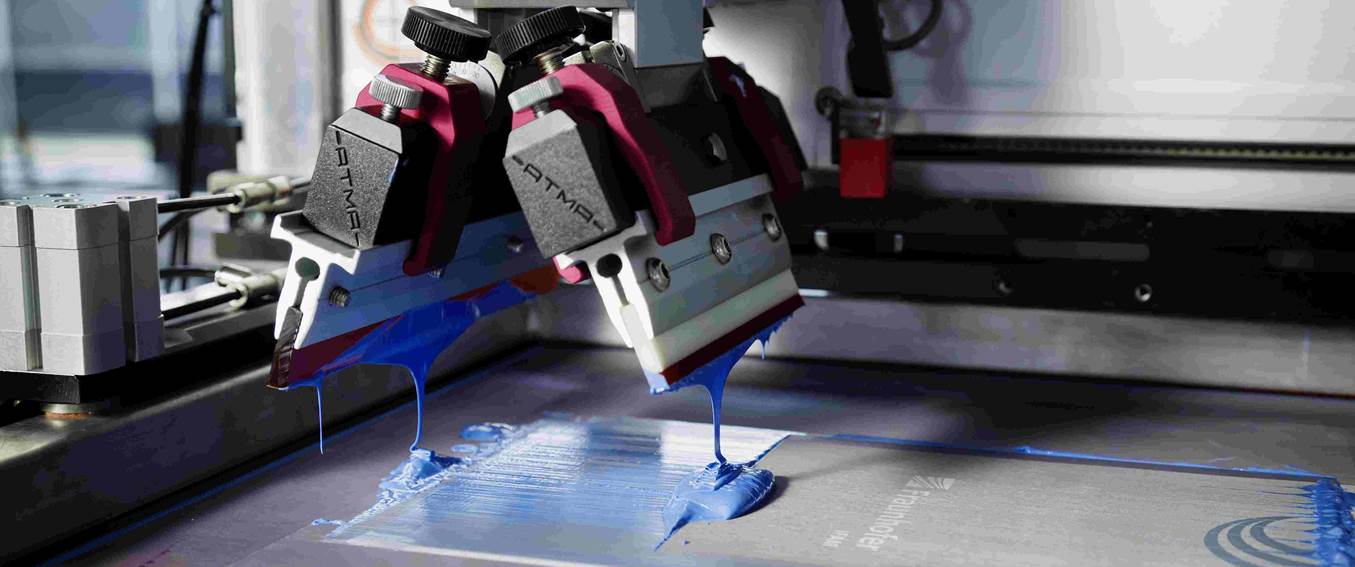

Functionalization of components using printing technologies

For customized functionalization of components using printing technologies, suitable inks and pastes are required. Fraunhofer IFAM has extensive expertise and capabilities for the development of printable inks and pastes. These range from the selection of suitable functional and additive materials, to the production / homogenization of the pastes and inks, to the subsequent printing and curing process.

Fraunhofer IFAM has extensive expertise in the development of printable pastes and inks. We use commercially available materials as well as inks and pastes developed in-house, which we formulate according to your requirements. For this purpose, we use our comprehensive technical and analytical equipment for the production and characterization of the inks and pastes.

Functional pastes

In the development of functional pastes, different formulations based on the following ingredients are possible:

- Filler (active material)

- Binder system

- Additives

Printability tests can be carried out at Fraunhofer IFAM. In addition, we also consider the possible post processes. These can be, for example, thermal drying, thermal / photonic sintering, or laser post-treatment.

Functional inks

In the development of functional inks, Fraunhofer IFAM has a unique selling point in the VERL process for the production of printable inks. In contrast to the classic wet chemical production of inks, this process, which is based on a sputtering process, allows more materials (pure elements as well as alloys) to be converted into printable inks:

- Target selection / process finding sputtering

- Concentration

- Printability tests

- Post process (thermal sintering, photonic sintering)

Fraunhofer IFAM develops printable inks and pastes for functionalizing parts and components. In the "Advanced Printing Technologies" department, the "Functional Printing" group has comprehensive know-how and the latest technologies for functional integration. The fields of application range from automotive engineering and energy technology to medical technology and life sciences.

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM