Manufacturing of FRP components using functionalized release film PeelPLAS®

Due to their low weight and strength, components made of fiber-reinforced plastics (FRP) are in particularly high demand in a wide range of industries, such as the aerospace or automotive industries. However, conventional demolding of FRP components by using release agents is very cost and labor intensive. In addition, the release agents can have harmful effects on the environment. At Fraunhofer IFAM, a plasma-coated release film has been developed which allows thermoset plastic components to be manufactured and safely demolded without the use of release agents. The component surface is free of contamination and can be painted or bonded directly.

Production without release agents: PeelPLAS® release film reduces material costs, increases productivity and protects the environment

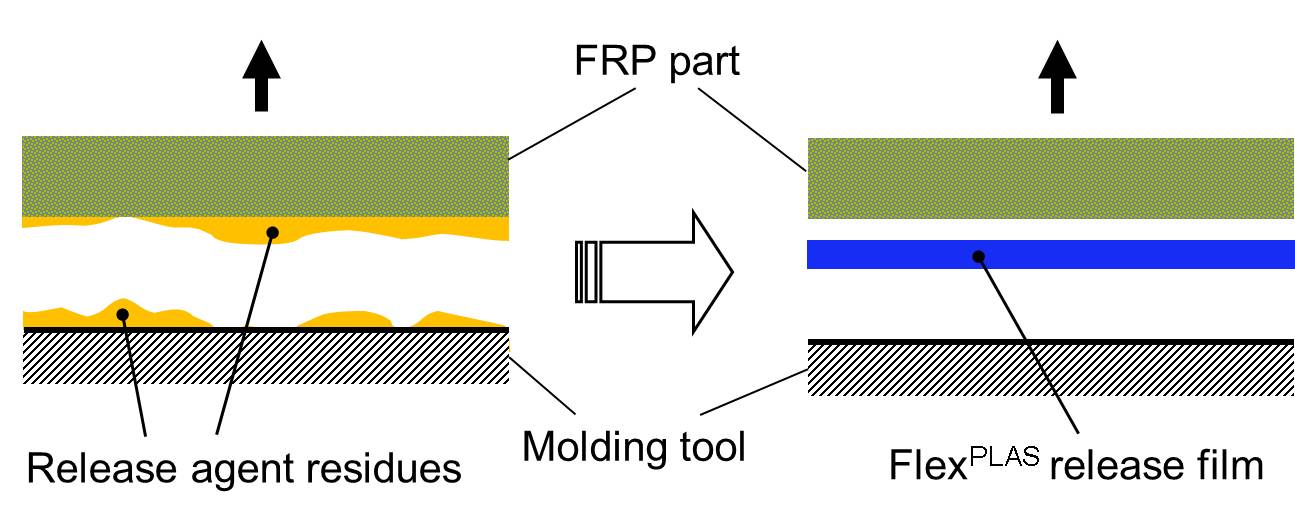

Conventional release agents are often used to safely release components from the mold after production. The release agent residues remaining in the process must then be removed from both the component and the mold by grinding or blasting. This is a time-consuming and cost-intensive process that also pollutes the environment and endangers the health of employees through considerable noise and dust emissions.

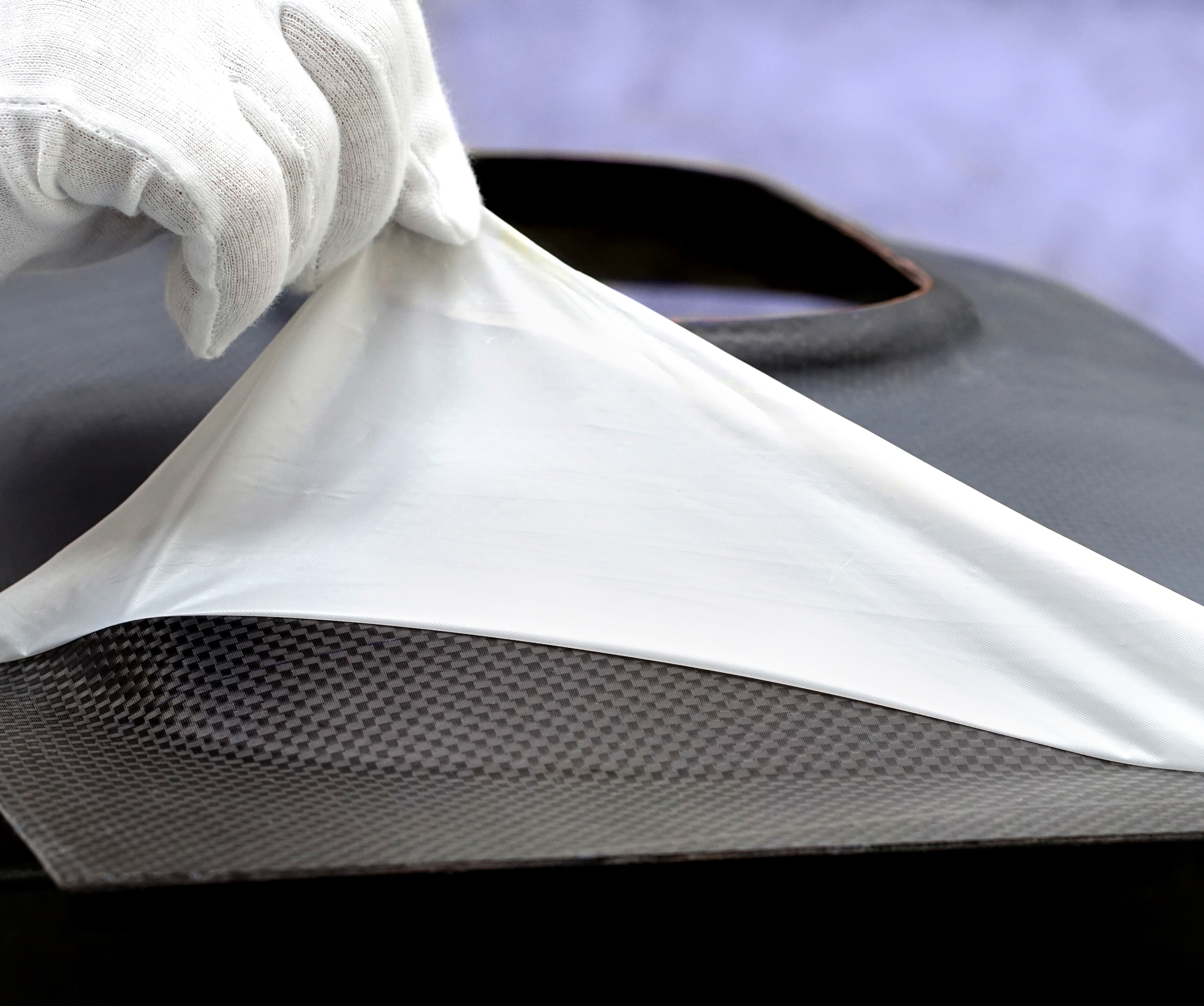

With the PeelPLAS® release film, Fraunhofer IFAM has developed a replacement for the use of release agents in the demolding of plastic components. The polymer film is provided with an extra-thin plasma-polymeric release layer. The special feature of this ReleasePLAS® coating is that it adheres optimally to the polymer film, but exhibits a very good release effect compared to most reactive resins. The highly elastic film can withstand elongations of up to 300 percent and curing temperatures of up to 190°C, and can thus be applied without difficulty even to curved and structured molds. It is pulled onto the mold surface like a second skin and can be removed from the component surface without leaving any residue after the thermoset matrix has cured. A clean component surface is exposed, which can be further processed directly. If the film is initially left on the component, it can also serve as transport protection and protect the component from contamination during further processing such as trimming or drilling.

Different polymer films are used depending on the requirements. The flexible release films are suitable for most reactive resins, such as epoxy, vinyl ester, cyanate ester and phenolic resins. Another advantage is that in-mold coatings can also be used for in-mold coating, for example with polyurethane gelcoats. In this case, the coating is cured together with the component in a single production step.

Prepreg, resin transfer molding, press molding - a wide variety of production processes are possible

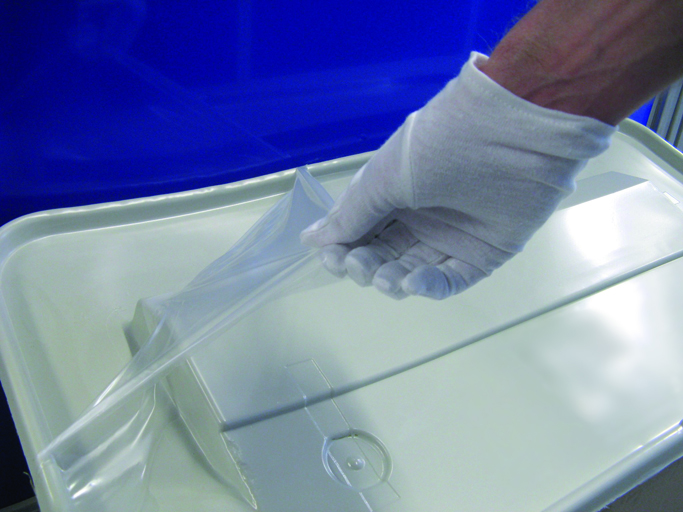

Originally, the PeelPLAS® release film was developed for the production of large structures made of fiber-reinforced plastics (FRP) - such as those used in the construction of aircraft or wind turbines. In the meantime, the researchers at Fraunhofer IFAM have further developed it for many additional manufacturing processes. These include the (vacuum) infusion process and prepreg technology, as well as resin transfer molding (RTM) and pressing processes. The release film is stretched onto the mold like a second skin by evacuation and can thus be used even in complex geometries. This is usually possible even at room temperature. The necessary sealing at the mold edge, as well as the required vacuum connection, can usually be implemented with simple means on existing molds. This innovative demolding technique can therefore be implemented at particularly low cost. If the use of the release film is already taken into account during system planning and mold design, the cost-effectiveness is increased even further.

Dr. Matthias Ott is deputy head of the "Plasma Technology and Surfaces" department at Fraunhofer IFAM. The institute is working for many years on the development of environmentally friendly release agent substitutes. In the "Plasma Technology and Surfaces" department, the focus is on coating technology. The plasma-polymeric release coatings are used in the automotive industry, among others. With the PeelPLAS® release film, the production of large fiber composite structures can now also be realized.

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM