Thin separators made of sulfide or polymer using a slot die

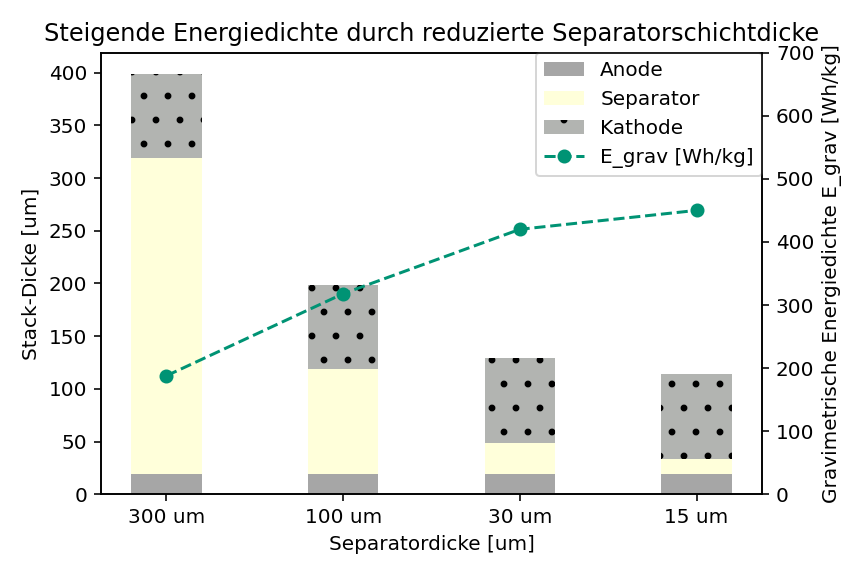

Solid-state batteries with high energy density require thin separators made of sulfides or polymer electrolytes with layer thicknesses of less than 30 micrometers. With slot die coating, we can apply slurry tailored precisely to requirements and produce separator layers.

The production and characterization of these layers requires expertise in materials, processes, and analytical methods, which are bundled at Fraunhofer IFAM.

Challenges in process technology

The development of solid-state batteries poses specific challenges in process technology. In particular, upscaling the manufacturing of components and cells from the laboratory scale requires further development of the shaping processes. In laboratory cells for materials research, powder pellets with separators several hundred micrometers thick are used. For commercial cells, however, the separator thickness must be reduced to less than 30 micrometers to achieve high energy density in solid-state batteries. Since the format is also being enlarged and the cell packaging is changing from reusable metal housings to pouch film, powder pellets cannot be used; instead, dense layers are required.

Slot die coating as a solution for thin separators in solid-state batteries

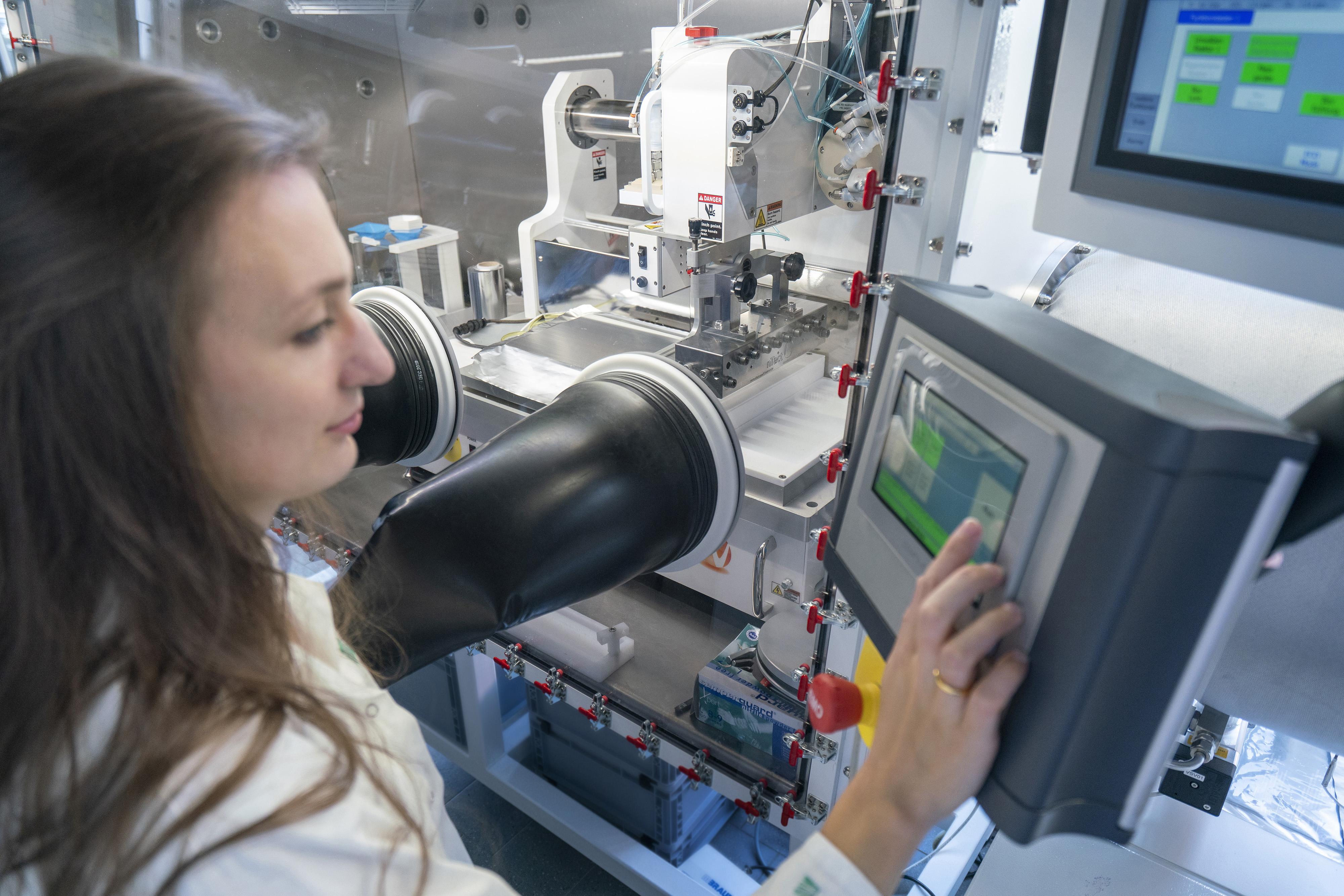

Slot die coating offers a promising solution for achieving this goal. This method enables substrates to be coated with thin fluid films, such as a polymer separator solution or a ceramic slurry with sulfides. Slot die coating offers a well-controlled and reproducible process. At Fraunhofer IFAM, both the substrate and the fluid can be freely selected.

Depending on the research task, various films can be used as coating substrates:

- Smooth films

- Release films for subsequent removal and transfer of the separator

- Metal films for electrochemical characterization of the separator

- Pre-produced composite cathodes for direct, application-oriented implementation of the process

Both polymer electrolyte solutions and sulfide dispersions are used as fluids to manufacture solid electrolyte separators. Implementation is possible with common solid electrolytes based on polymers and sulfides.

To exclude the influence of moisture on moisture-sensitive materials and to maintain high product quality, Fraunhofer IFAM has a slot die in a glove box that enables processing under inert conditions. With a slot die tool width of 20 cm, coatings in DIN A4 format can be applied for large-format cells. However, small quantities for testing new materials are also possible.

From material selection to product characterization

Our range of services includes not only the actual coating, but also the selection and characterization of the starting materials, such as polymer binders, as well as the solutions and products. The rheological properties, in particular viscosity and surface tension, are determined depending on the fluid composition. For dispersions, the sedimentation behavior is also of crucial importance in determining the maximum process duration. These parameters are crucial for successful, defect-free coating and form the basis for predicting suitable coating parameters using Design of Experiment.

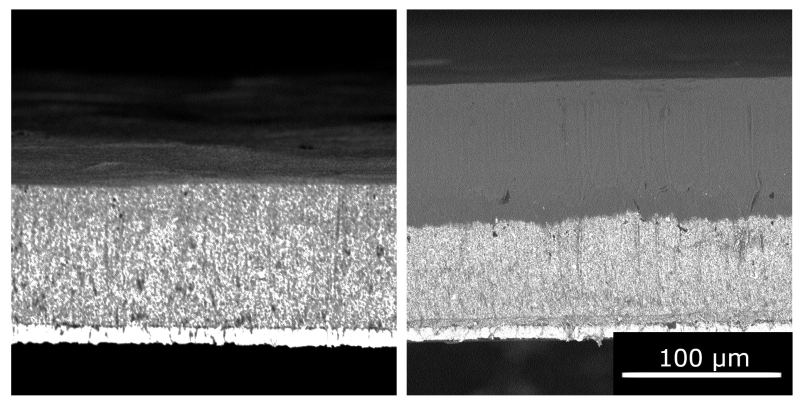

By covering a wide range of process parameters, we ensure both reproducibility and experimental determination of the process window. Product analysis includes in-depth examination of the coating in terms of defect structure, layer thickness, and surface roughness to ensure the highest quality standards.

Example projects: BMBF FestBatt2 competence cluster: Thio platform and production platform

Our employees have already demonstrated their expertise in several projects. As part of the BMBF FestBatt2 competence cluster, Fraunhofer IFAM was involved in the Thio and Production platforms. In the Thio platform, Fraunhofer IFAM pursued a novel approach using slot die coating to produce thiophosphate-based separators. On the one hand, chemically stable and rheologically adapted slurries and the process parameters were evaluated. In the Production platform, the slot die process was established for the manufacture of polymer separators based on the polymers developed in the cluster. The influence of process parameters, such as application rate and temperature, on the layer quality was investigated and evaluated. The reproducibility of the process was evaluated.

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM