Wettability of surfaces: For the secure adhesion of adhesives and coatings

The wettability of a component plays a key role in ensuring that adhesives, coatings and varnishes adhere stably and securely to its surfaces. In addition, there are self-cleaning or release coatings for which only low wettability is required. To ensure that a surface is optimally prepared for its application, Fraunhofer IFAM offers various test options such as contact angle and test ink measurements. In addition, solutions for optimizing component surfaces from cleaning to activation to coating can be developed for you on request.

Characterize wetting properties: From contact angle measurement to test inks and dewetting

For many industrial applications, it is essential that adhesives, coatings or varnishes and surface properties are optimally matched. The wettability of a surface depends on various factors such as the surface chemistry and composition (which often differs from the base material), the surface structure (roughness), but also on process-related effects. For example, if a surface is contaminated by grease or release agent residues, paints may flake off or adhesives may not adhere properly. This can lead to high costs and further serious consequences, e.g. if a bonded structure on a car cannot withstand an accident. It is therefore very important to determine the wetting of surfaces prior to an adhesive bonding, painting or coating process. There are various ways of doing this:

a. Test inks

The simplest method of characterizing the wetting properties of various materials such as metal or plastic is by means of test inks. These are applied to the test surface with different surface tensions and the respective wetting is assessed visually. The advantages of this method lie in its rapid and direct application. However, since it is a manual test method, user-dependent deviations and misinterpretations may occur.

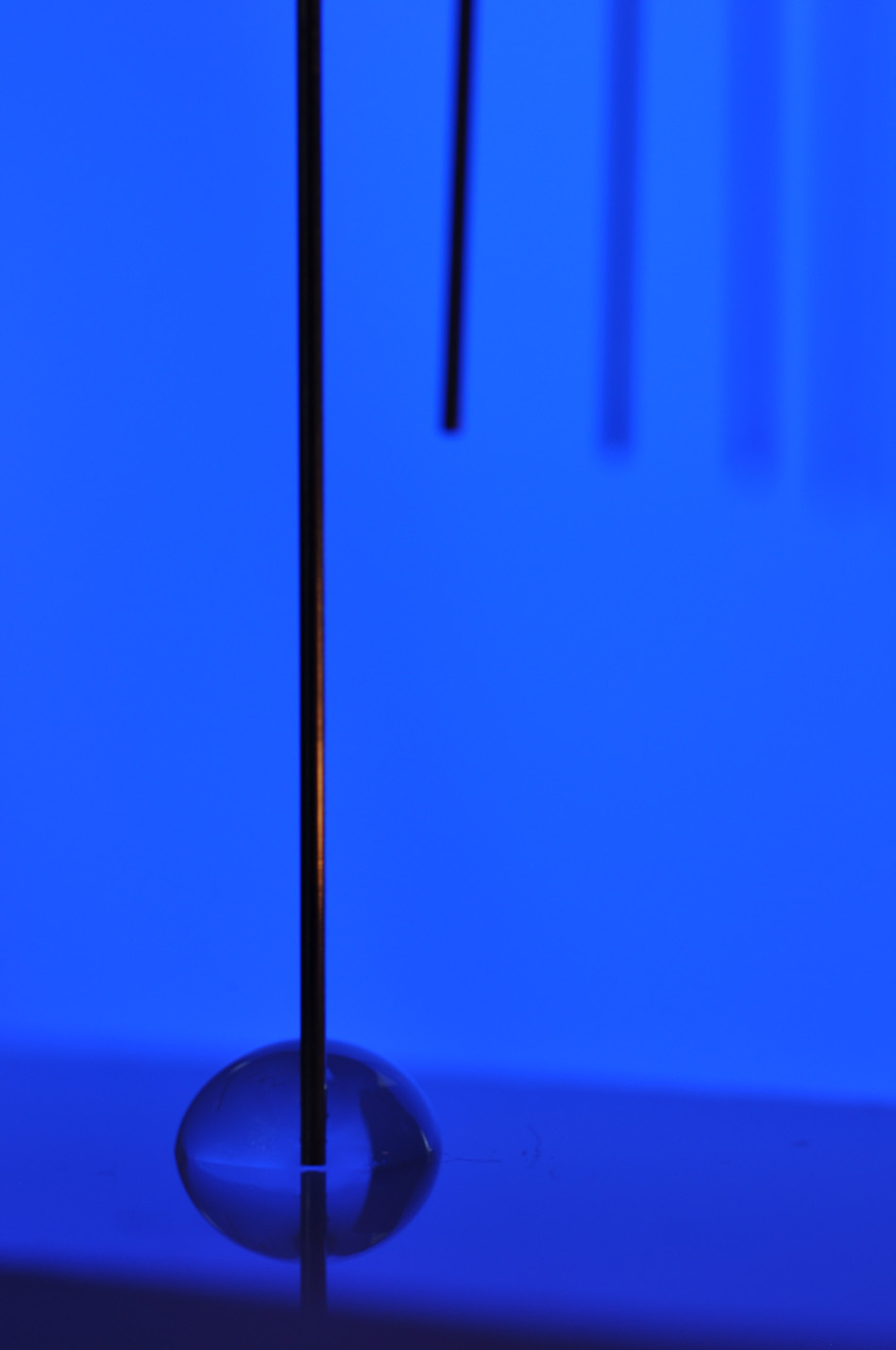

b. Contact angle measurements

Contact angle measurement is one of the most reliable methods for determining wettability. By using liquids with different properties, the surface energies can be evaluated with respect to their disperse and polar fractions. This allows a very good wetting prediction and an accurate understanding of the states present or generated on the surfaces. For this purpose various measurement systems are available at Fraunhofer IFAM - from mobile devices for contact angle measurement in the production line on site to fully automated systems for series measurements and process developments. Contact angle measurement is particularly suitable for small areas and local measurements. If large area information is required, the aerosol wetting test can be used. (Link to the aerosol page)

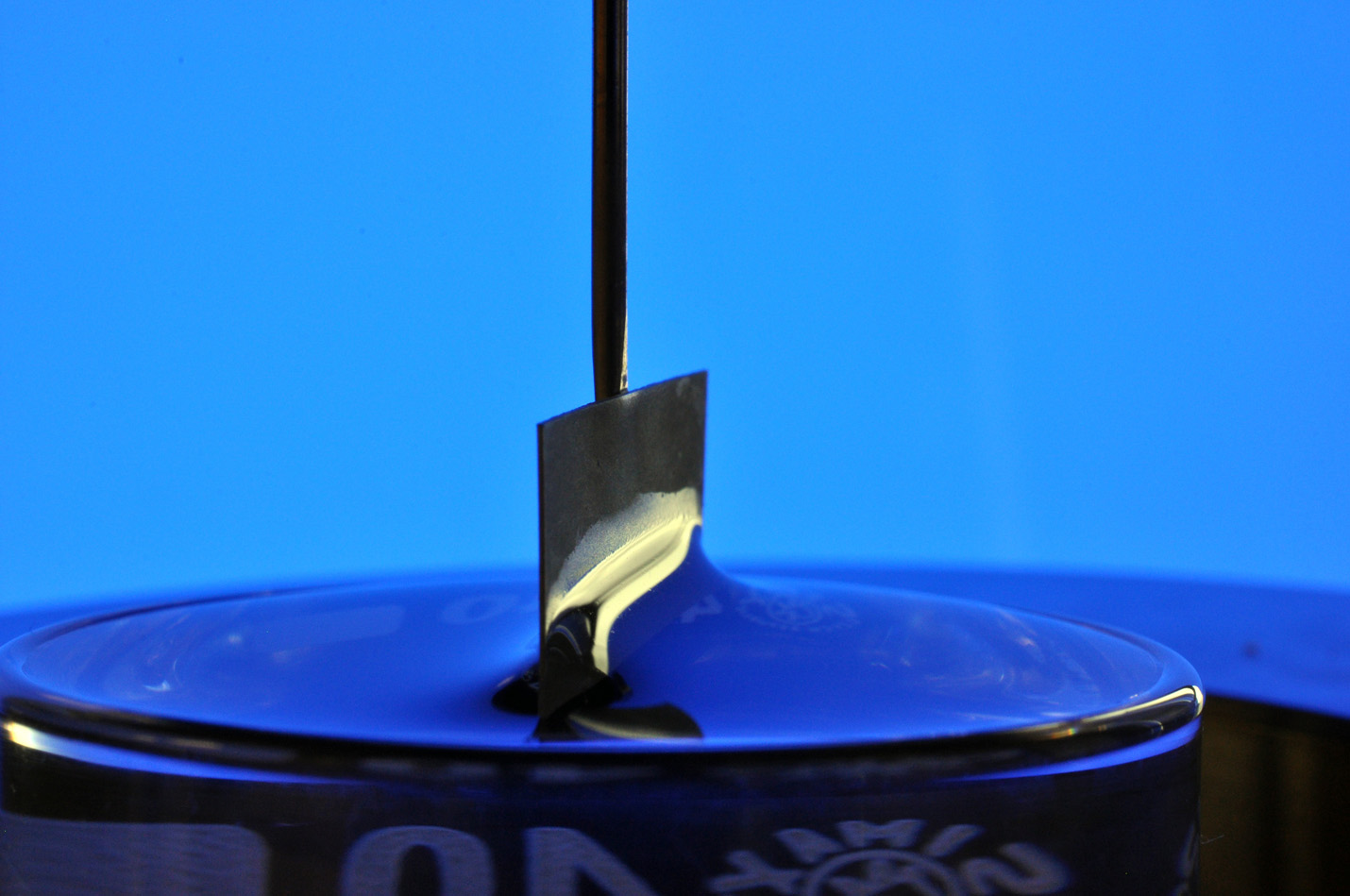

c. Dewetting

In addition to the measurement of wetting, the analysis of dewetting, i.e. the rolling off of liquids, is also of great importance for the understanding of surfaces. This allows, for example, to study and control the dosage of inoculation syringes, the self-cleaning ability of surfaces, but also the growth of ice by raindrops. Different devices are available at the institute which can analyze the wetting and dewetting behavior under variable angles of inclination.

d. Powder and fibers

In addition to simple surfaces of components, the wetting behavior of powders and fibers can also be investigated with the aid of a tensiometer, so that the treatment of these materials can be developed in a demand-oriented and targeted manner. In this way, the dispersibility of paint fillers can be predicted and efficiently optimized, as can the interaction of resins with carbon or glass fibers.

We support you in optimizing your surfaces

The basic rule is that the surface energy of a solid must be higher than the surface tension of a liquid for wetting to occur. The wettability of surfaces can be specifically influenced by appropriate surface treatment. Plasma technology offers optimum conditions for this. Treatments with various gases and gas mixtures at atmospheric or low pressure, or with VUV and laser beams, allow surfaces to be individually functionalized.

Jost Degenhardt is a project manager in the "Atmospheric Pressure Plasma Technology" working group in the "Plasma Technology and Surfaces" department. Functionalized surfaces are the focus of the research work. Surface technology is one of the core competencies of Fraunhofer IFAM. Our great advantage lies in the fact that we combine a wide variety of fields such as paint and lacquer technology, adhesive bonding technology, adhesion and interface research, and comprehensive analysis methods under one roof. This allows us to take a holistic view of your individual issues and provide you with the best possible support in the optimization and development of your products.

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM