With GelCasting, Fraunhofer IFAM in Dresden has established a new technology for the manufacturing of metallic components. In the hybrid process, shaping takes place via suspension casting in molds at room temperature, which takes less than 1 minute even for > 1 kg components. The molds can be manufactured with any technology, resulting in high flexibility in process design.

GelCasting

Current activities and range of services

- Development of new material solutions for your application (based on all sinterable pure metals or metal alloys)

- Development of individual process solutions for the production of complex single parts up to mass production

- Development of material- and geometry-dependent debinding and sintering processes including in-situ gas phase analysis

- Support in component design, design adaptation and component selection from customer portfolio

- Feasibility studies, comparative studies and process optimization according to customer requirements

- Cost-effectiveness analysis of the entire process chain in the respective application case

- User-specific objective consulting taking into account current AM and PM technologies (Binder Jetting, Additive Screen Printing, MoldJet, FFF, MIM, GelCasting, PBF-LB, PBF-EB, LMM, Cold Metal Fusion)

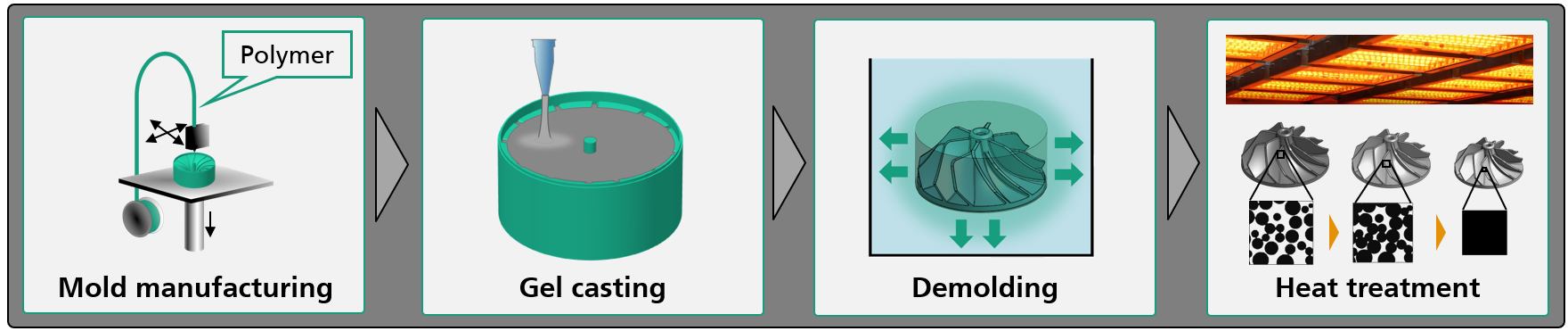

Process description

The GelCasting process is a suspension-based shaping route and combines the advantages of additive manufacturing with a high degree of freedom in process design. In the process, a metal powder suspension is poured into a mold and solidifies without sedimentation after a short time to form a homogeneous solid green part consisting of metal powder and organic binders. After demolding, a short drying phase follows.

Thus, the green part has high strength and excellent mechanical processing properties. In the subsequent heat treatment process, the organic components are burned out (debinding) and the component is compacted (sintering). Sintered parts produced in this way achieve 95 % - 99 % of the theoretical material density. The typically low linear shrinkage of ~ 14 % is very homogeneous and isotropic.

Schematic process flow with additive mold production using the FFF process and lost mold.

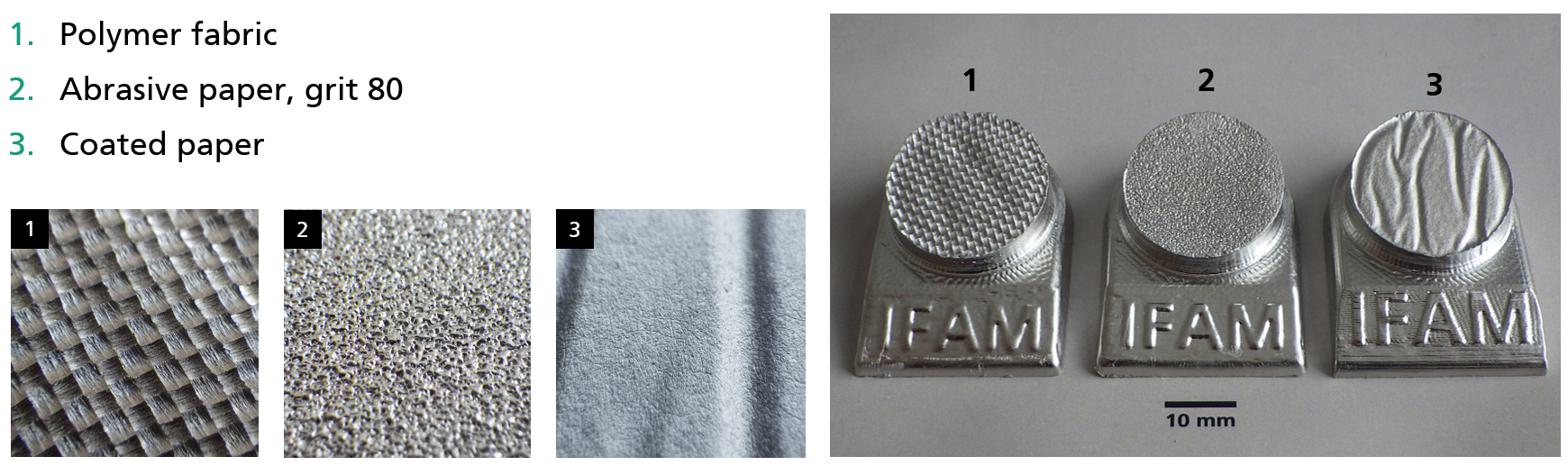

The freedom in process design consists in the individually designable casting process (e.g. gravity casting, vacuum casting, low-pressure casting) and the freely selectable mold production as a lost mold (e.g. FFF mold, wax mold) or permanent mold (e.g. silicone mold, metal mold). In this process, the surface quality of the mold is transferred 1:1 to the component, making very high surface qualities or finely structured surfaces possible even without post-processing.

Therefore, surface finishing is largely obsolete. The process itself thus offers the possibility of cost-effective single-part production on a laboratory scale, but can also be scaled up for mass production on an assembly line, provided the geometry permits.

Surface study - mold production with insert materials to create fine textured surfaces. The insert materials used are listed, the mold was produced using FFF, model made of stainless steel 1.4404.

At a glance

- Suspension casting process with individual lost AM molds or permanent molds

- Highly flexible process design from single parts to mass production

- All sinterable materials conceivable: Pure metals (e.g. copper, iron, titanium, molybdenum, tungsten,...) and metal alloys (e.g. stainless steel, tool steel, high temperature alloys, nickel based alloys, titanium alloys, copper based materials,...). Realized so far: 316L (1.4404), M2 (1.3433), WC-Co (β)

- Internal channels possible (without powder residues inside)

- High surface qualities and diverse structuring possible

- Resolution and structure sizes depending on mold production

- Large parts with > 1 kg possible, wall thicknesses up to 30 mm successfully proven

- Nearly 100 % material utilization

- Mechanical processing possible in the green state (e.g. CNC machining or surface treatment)

For information on the 3D gel casting process or discussions about common project topics, please contact us. We are looking forward to a joint cooperation!

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM