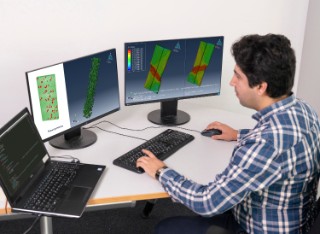

Automation is one of the most important strategies for increasing efficiency in production. The positioning and drilling end effector newly developed for a portal system to automate the pre-assembly of stiffening elements (cleats) on CFRP integral frames for the manufacture of aircraft fuselages – made available by project partner Airbus Hamburg – enables production rate increases both with constant quality and at lower costs.

more info Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM