The selection of the right adhesive is a fundamental element of any manufacturing process, because if an unsuitable adhesive is used, this can lead to problems such as corrosion, reduced bond strength over the lifetime, adhesive creep with an increasing risk of failure of the bonded joint, and many other difficulties. For this reason, the experts at Fraunhofer IFAM have specialized, among other things, in providing manufacturer-independent support for customer-specific adhesive selection.

Holistic view of the adhesive bonding process

At the beginning of the process, the adhesive bonding process and the general conditions to which production is subject must be considered holistically in order to find the best possible adhesive bonding solution. This applies, for example, to the number of units in which the product is to be manufactured, the ambient conditions or the desired degree of automation - we summarize these and all other relevant aspects for you in a comprehensive requirements profile.

Based on these requirements, a basic selection of suitable adhesive types can then be made for the planned production. For this purpose, we carry out extensive research in the internal database of Fraunhofer IFAM and on the market.

Early favoritism of adhesives through characterization

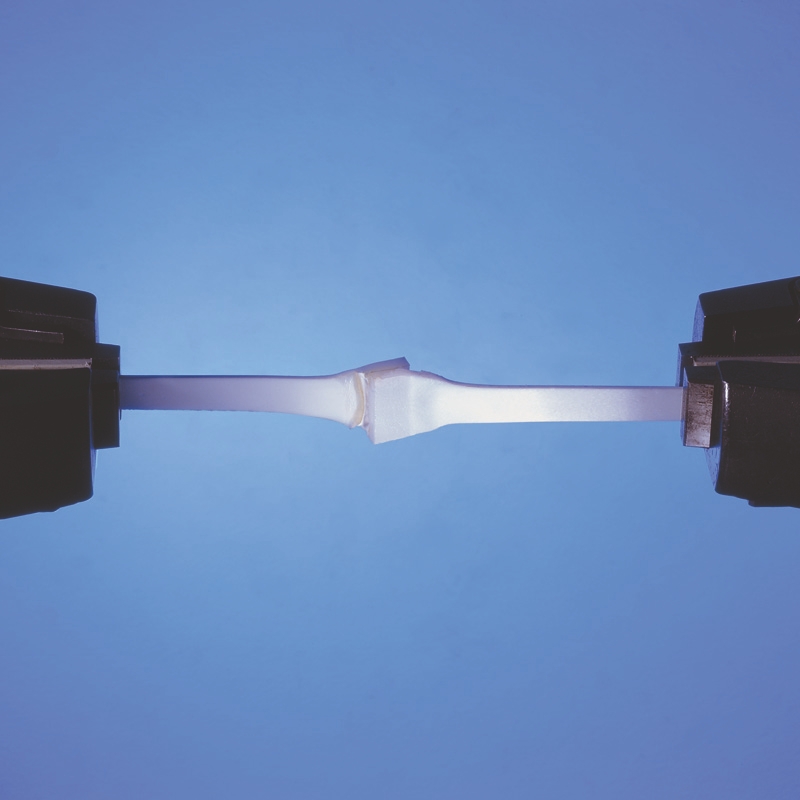

Once the choice of adhesives has been narrowed down, e.g. by checking the main requirement, we test the adhesives in question using extensive characterization methods in order to compare them with each other and check their suitability for the process. For example, the flow behavior of the adhesives can be determined by rheological characterization, but it is also essential to determine the mechanical properties of the adhesives. With the aid of these characteristic values, it is possible to favor adhesive systems at an early stage without having to produce real components at great expense.

To test the adhesion, we can not only offer methods such as tensile shear tests or compression shear tests, but also carry out individual project-specific adhesion tests that take place on the real components and thus on the original surfaces (condition) of the joining partners.

Weathering has an effect on the adhesive bond

Depending on where and how the product is to be used, additional climate change tests and climate outsourcing according to the standards of a wide range of industries are recommended, for example a test according to PV1200, which is common in the automotive industry. In this way, the resistance of the adhesive bond under the respective weather conditions can be guaranteed.

However, it is not only the durability of the adhesive bond that is an essential factor; the ability to remove the bond and subsequently recycle the materials used is also playing an increasingly important role. Here, too, Fraunhofer IFAM applies its extensive knowledge of materials science in order to be able to design the bond not only reliably and durably, but also sustainably and in the sense of the circular economy.

In addition to analyzing the thermo-mechanical properties, rheology, and adhesive strength of the adhesives, Fraunhofer IFAM still has very extensive equipment and methods, some of which have been developed in-house, to make the best possible adhesive selection for you. Here you can find a complete list of the methods that can be carried out and the available equipment.

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM