Increased robot precision through error compensation

Low-cost industrial robots have been established worldwide as all-rounders in automated production. Continuous system improvements now also allow them to be used in applications with ever-increasing precision requirements, such as the mechanical processing of easily machinable materials. In many cases, flexibility and cost efficiency are proving to be decisive advantages over established machine tools. However, in order to achieve the highest possible accuracy, industrial robots must be calibrated to meet the requirements regarding all relevant parameters. At this stage, the Fraunhofer IFAM in Stade, Germany, has identified a very high potential that can be leveraged with relatively little effort.

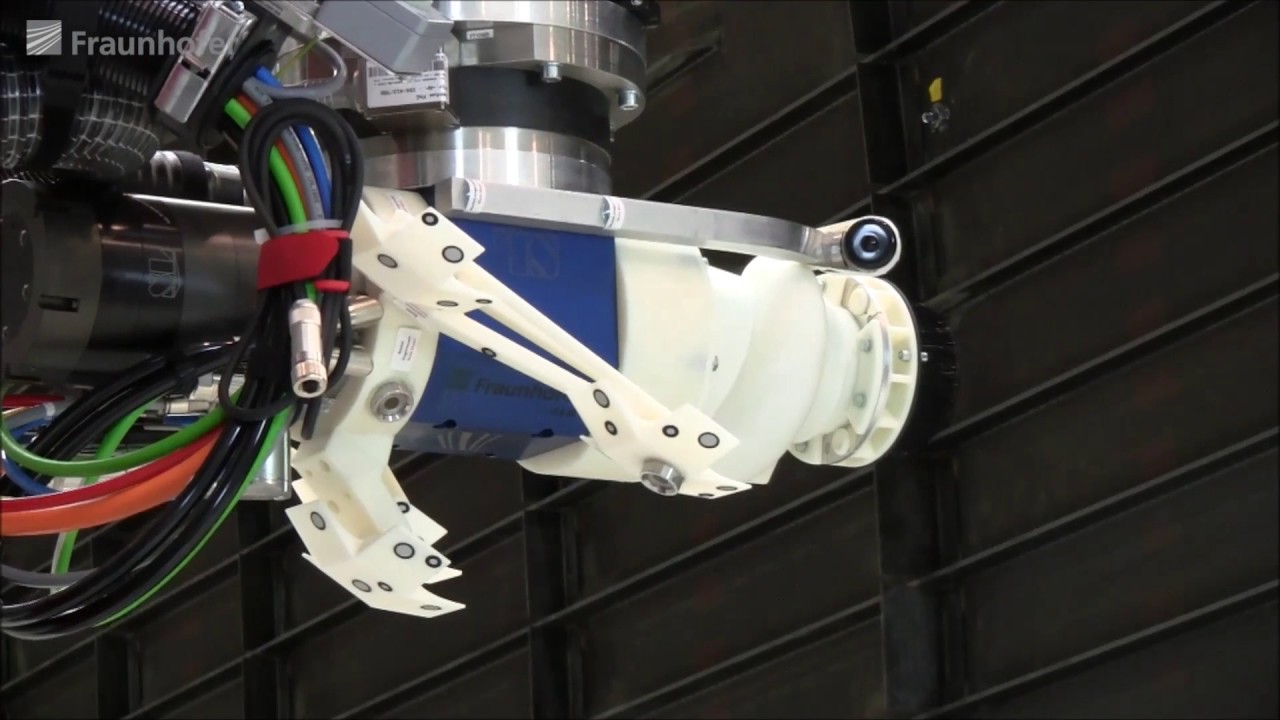

In addition to the high-precision calibration presented in this article, the experts at Fraunhofer IFAM are also developing solutions to increase robot accuracy by integrating sensors, advanced control algorithms, more powerful drives, highly rigidly designed arms and axes or functionally optimized end effectors.

Competition for machine tools: High-precision industrial robots through calibration

Due to unavoidable manufacturing tolerances, industrial robots have individual deviations from the ideal system. Without knowledge of these deviations, errors of up to a few millimeters can result in the workspace when approaching target poses in robot systems.

On the way to optimize these robot systems, an extraordinarily powerful software application for model-based calibration of industrial robots has been developed which enables high-precision robot use. A key element of the application is a very extensive mathematical model that includes over 200 parameters to describe robot kinematics. The individual parameter set of a robot is determined using the measurement data in an optimization calculation which is particularly challenging due to the high number of parameters, but also particularly accurate. Conventional solution methods reach their limits here, as parameters interact with each other in complex, sometimes ambiguous ways. With the help of a numerical optimization approach developed at the Fraunhofer IFAM in Stade, these parameters can be reliably determined despite the pronounced ambiguity of the problem.

During calibration, the robot is moved into a variety of positions and its actual pose is registered using a laser tracker. The calibration is carried out using the “CaliRob” calibration application developed by Fraunhofer IFAM which controls the robot and measuring system. The identified parameters of the robot are validated on test positions and transferred to the robot controller. The method achieves an additional increase in performance by recording parameters that go beyond the standard robot models of the manufacturers. The real-time capability of the mathematical robot model means that correction signals are reliably calculated in the interpolation cycle of the controller and synchronously applied to the robot axes

The robot developers use the enormous potential of real-time-capable interfaces to influence the robot path not only in connection with calibration, but also to implement real-time-capable control loops with external measuring systems, such as laser trackers or laser profile sensors.

Robotic precision enhancement from Stade

The Fraunhofer IFAM in Stade is a reliable partner for direct R&D services as well as for constructive cooperation in research projects. In addition to the implementation of the CaliRob calibration application tailored to individual requirements, the institute offers activities in the research and development of precision applications in the field of robotics. These include, amongst others:

- Design of calibration workstations using the CaliRob calibration application under license

- Development of processes and control loops with real-time connection of sensors and measuring systems

- Testing of demanding applications on high-precision robots, for example

- mechanical machining of fiber composites and metals

- highly dynamic and path-accurate guidance of measuring equipment

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM