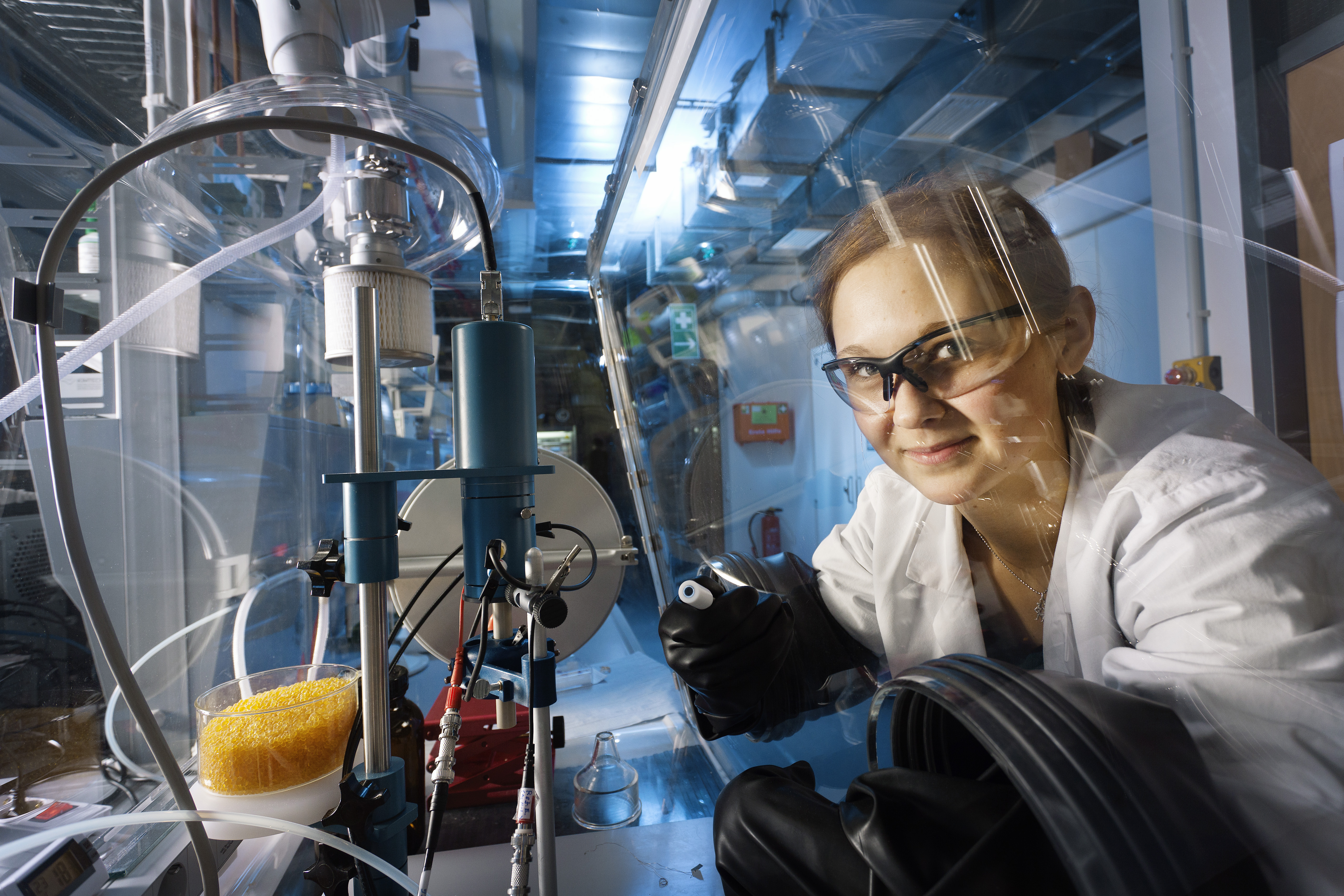

Laboratory for the development of energy storage materials and battery cells

The underlying active materials are the starting point for cost-effective and ecological energy storage devices and batteries with high energy density, performance, lifetime, and efficiency. Fraunhofer IFAM has extensive analytical capabilities for your individual issues.

Furthermore, we offer guidance and support in all aspects of material development and validation for electrical energy storage systems and battery cells:

- Material and process development from powder to cell

- Production and testing of battery cells with customer-specific materials and formats

- Battery/aging tests for all sizes and types at cell and module level (up to 6 V or 50 V, or 10mAh to 20Ah)

- Battery monitoring, aging, lifetime and safety

- Scientific project support, studies and expertises

- Research, evaluation and consulting on battery related issues.

We are an interdisciplinary team of scientists and technicians who are happy to support you in implementing new ideas and concepts in your products.

Material and component development for modern energy storage systems

The aim of component development is to realize the potential of new materials at the component level as well. Decisive influencing factors here are:

- the electrical conductivity

- the specific surface area

- the porosity

- particle sizes and morphologies

- (electro-)chemical stability

- the production scalability

In addition, another important aspect is the basic electrode design, which must always be adapted to the respective materials. Applied material development thus represents the link between basic research and the battery cell.

We deal with established and modern battery and energy storage technologies within the scope of material and component development.

Cell analysis and battery aging

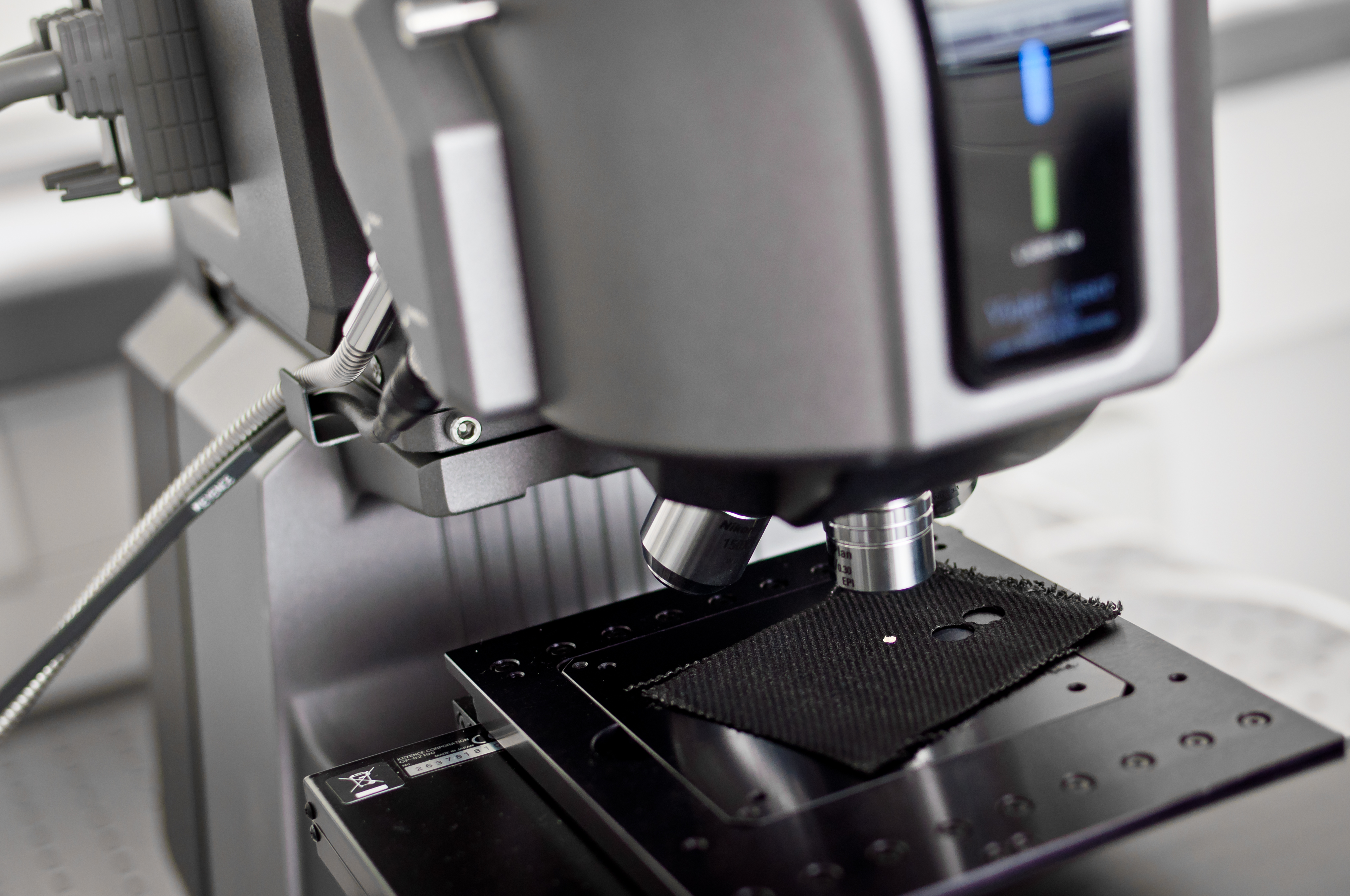

Improving the energy and power density of electrochemical energy storage systems requires a comprehensive understanding of the material properties. In addition to the standard analysis for characterizing the active materials and electrodes, we also make targeted use of the special methods of in situ and post-mortem analysis to gain knowledge of the electrochemical processes during ongoing cell operation.

Our (electro-)chemical-physical laboratory includes the following analytical methods for material and cell characterization:

- Digital laser microscope

- Scanning electron microscopy, coupled with energy dispersive X-ray spectroscopy (SEM/EDX, in argon glovebox)

- Thermogravimetry, coupled with mass spectrometry and infrared spectroscopy (TG/DSC-MS-IR)

- Gas adsorption (BET, Brunauer-Emmett-Teller method) and chemisorption

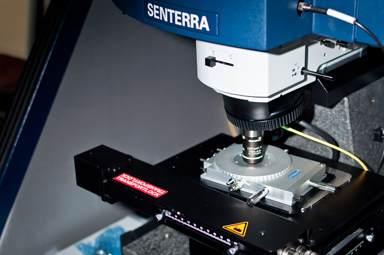

- Raman microscopy and in situ Raman spectroscopy

- Karl-Fischer titrator

- Impedance spectroscopy with DRT analysis, cyclic voltammetry

- Battery cyclization and aging test

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM