Flexible machine concept for production processes of large components

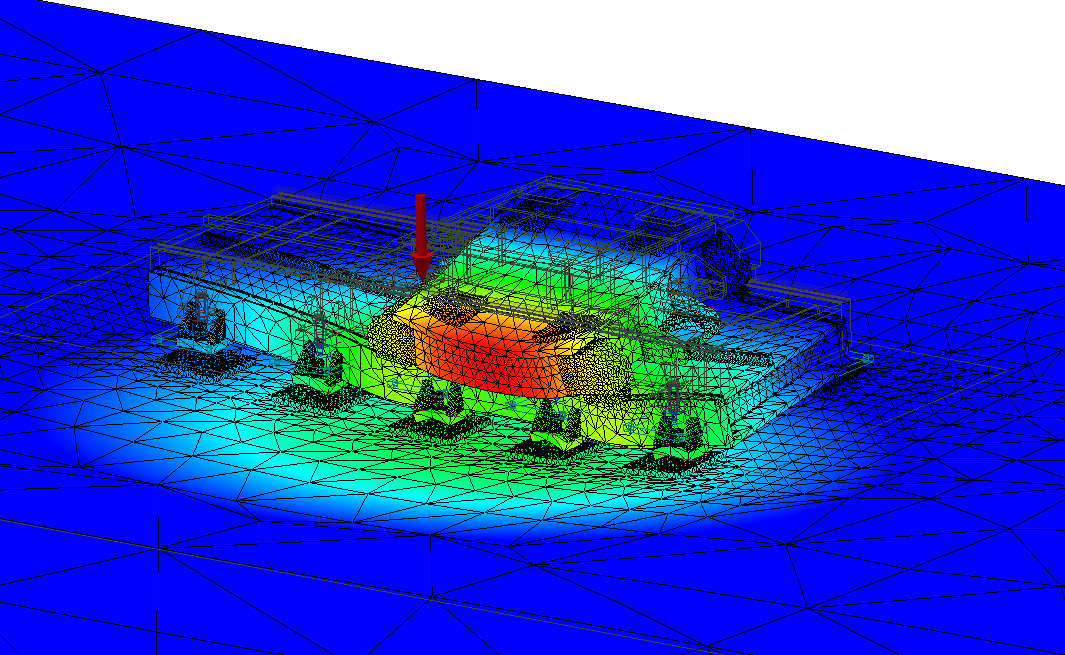

Industrial robots (IR) with a serial kinematic structure enable high flexibility in modern production processes while taking up little space. The combination of these serial kinematics with external linear axes results in versatile and adaptable machine concepts for manufacturing, even for the production of large components.

- high flexibility of the system thanks to the modular configurable linear axis

- less space required due to the smaller footprint of the robot and linear axis carriage

- increased productivity thanks to coordinated station changes and task sharing using several industrial robots on one linear axis

- fail-safe, as individual robots can be maintained or replaced independently without affecting the functionality of the other robots

- lower investment volume

At the Fraunhofer IFAM in Stade, these system concepts are used in various process steps in the production of large components. They include, for example, machining, assembly, joining, application as well as metrology processes. In order to meet the high accuracy requirements of these processes, our expertise includes hardware and software developments to improve the properties of the “linear axis with industrial robot” system concept.

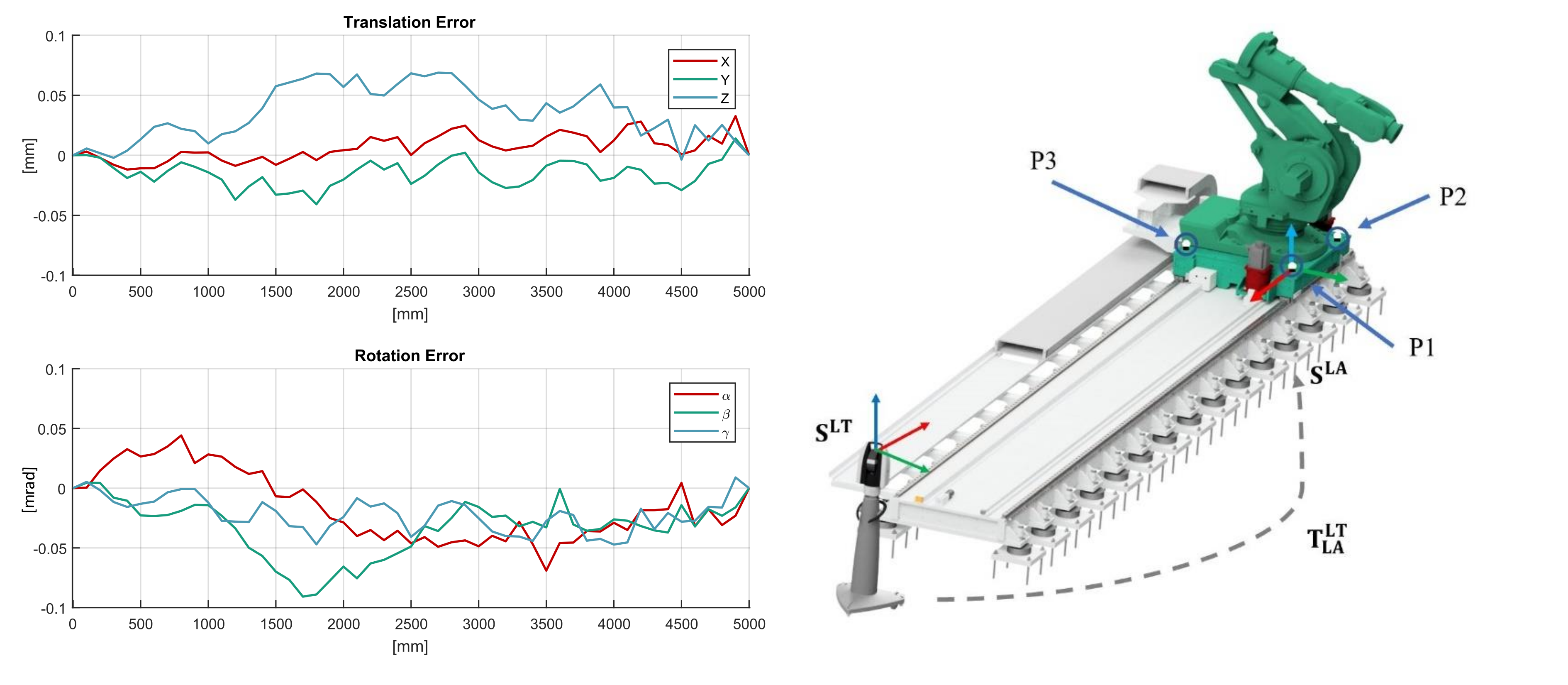

Calibration of geometric errors

For the calibration of the linear axis, methods have been developed to determine and compensate for deviations from linear models. Conventional control systems usually offer the option of describing the external additional axis with a 3D vector. For example, cubic B-splines can be used to capture further deviations in order to approximate the interpolation of the measured deviations to the linear model. Using these mathematical functions, different curves of data points can be described continuously and differentiable. In addition to the translational deviations, the rotational errors must also be taken into account, which can lead to large deviations due to the kinematically induced lever arms at the robot tool center point (TCP). With the use of 3D coordinate measuring technology, the Fraunhofer IFAM in Stade offers the possibility of measuring the error variables.

The calibration methods developed are not only limited to external robot axes, but are also suitable for increasing the accuracy of linear drive axes in machine tools and large special machines.

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM