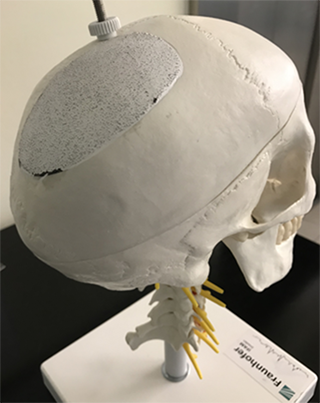

Defects of the skull calotte and midface usually require patient-specific implant materials. For this purpose, the OsteoPAKT project (funded by the BMBF) is developing implant materials with a novel treatment approach for individual, patient-specific bone replacement implants, especially in the cranial and facial region, with which functionally high-quality results can be achieved. At the same time a faster supply of the patient is made possible and a cost-effective treatment is realized, because by providing the individual implant within 48 hours multiple operations can be avoided.

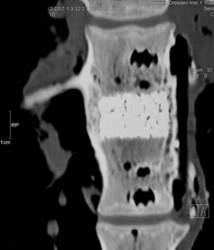

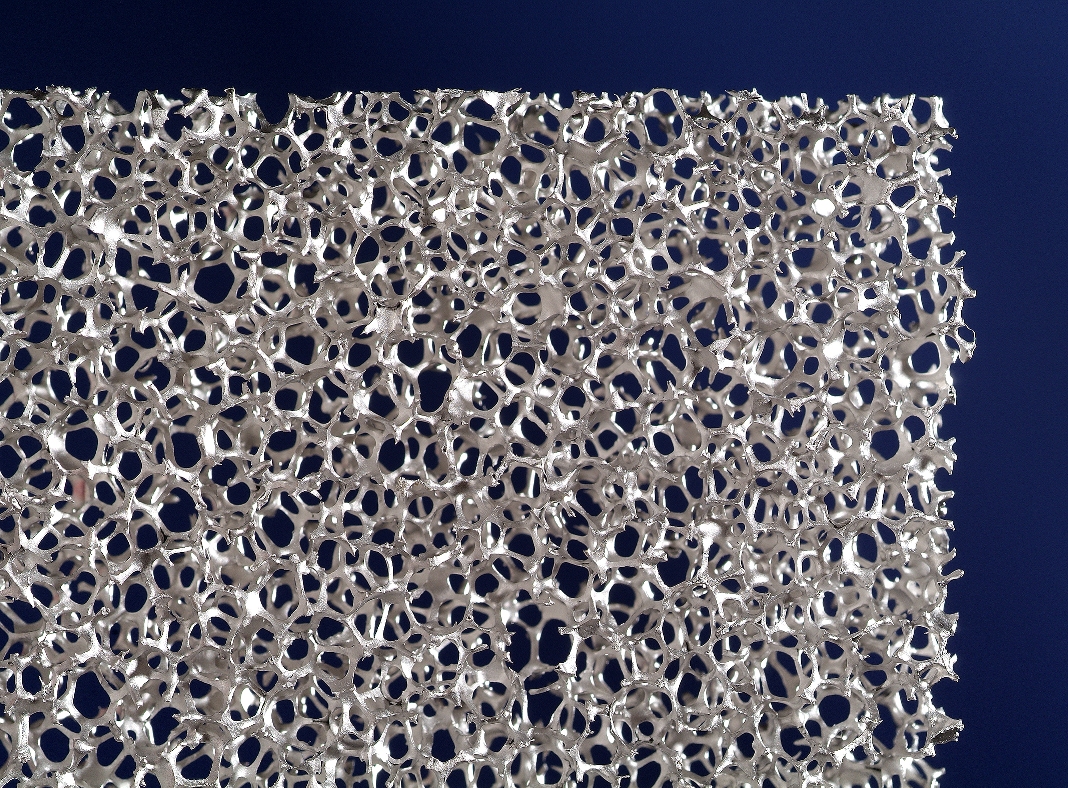

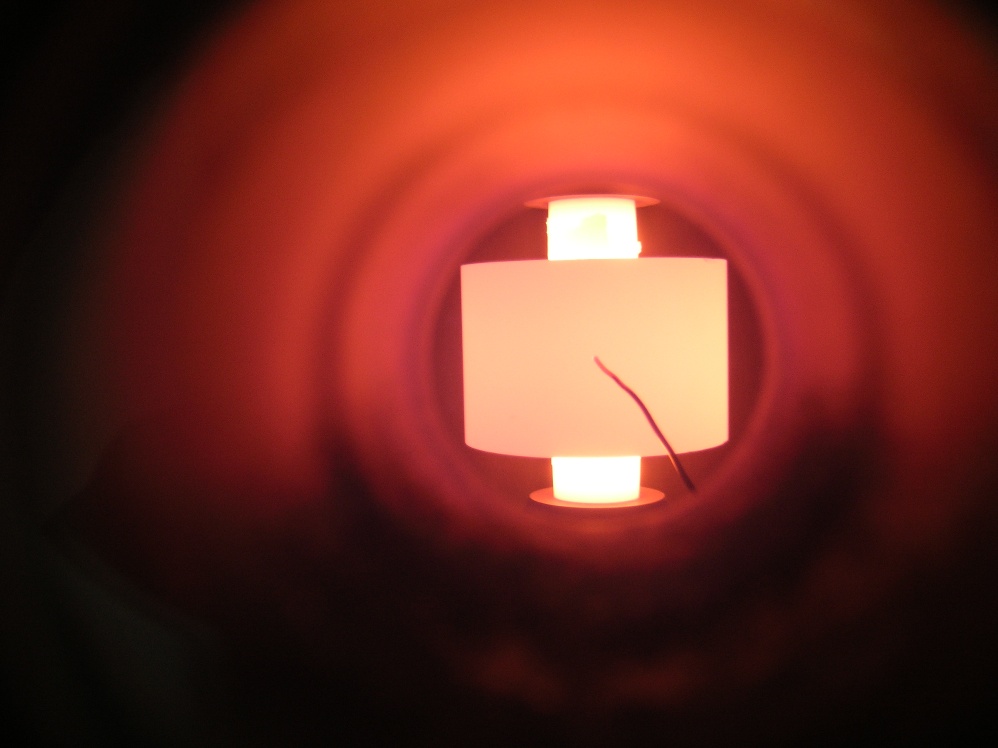

Using modern imaging, a digital model of the defect area is created. This model is used for the production of a negative stencil through 3D printing. This patient-specific three-dimensional template is used to shape the prefabricated composite material consisting of a titanium sponge and a bone cement paste. After the bone cement has almost completely dried and has been sterilized, the implantation procedure can be performed.

The ResorbM project (funded by the BMBF) is examining whether resorbable implants for the surgical treatment of craniosynostoses in infants and toddlers can be manufactured from molybdenum. On the one hand, the metal has a high mechanical strength, on the other hand, its resorbability makes further surgery to remove the implant unnecessary. This makes the procedure much easier for children to cope with. Since the handling of molybdenum implants will be similar to that of titanium implants, they will be seamlessly integrated into existing treatment processes and workflows in clinics. This should raise the quality of care in cranio-maxillofacial surgery for small children worldwide to a significantly higher level.

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM