Services

First and foremost, the business unit provides competent support in regard to the development of systems in power and process engineering for variable applications in multiple magnitude scales.

In particular, the offer addresses business partners or associate research groups who are interested in material-scientific and thermodynamic know-how from one source.

Examples for versatile complexes dealt with in the business unit are:

- thermo-technical and fluidic design of single components or entire technical systems such as

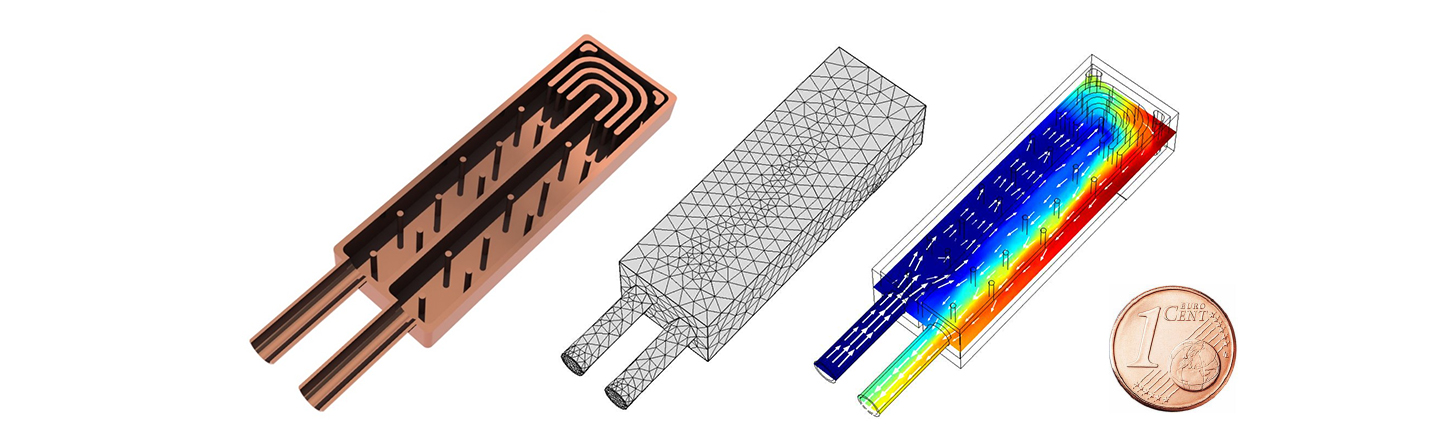

- efficient heat exchangers,

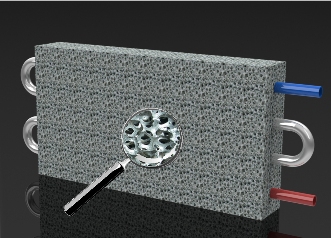

- high-performance thermal storage devices,

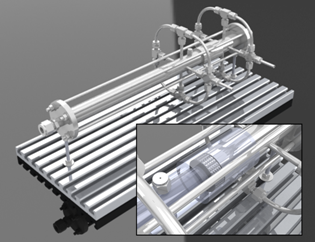

- evaporators / condensers,

- high-power temperature regulating systems,

- micro-cooling systems and many more,

- the definition of demands for optimised material systems and the interaction with accordant specialists,

- the characterisation and mathematical description of thermal and fluidic material properties,

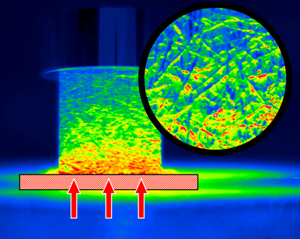

- the experimental validation of single assemblies or prototypical systems.

Core skills in the fields of thermal storage or heat transport and thermal management enclose

- computation of steady-state or transient temperature fields in (an-)isotropic systems,

- modelling of mass, momentum and heat transfer under variable boundary conditions (including phase change phenomena),

- measurement and/or computation of thermal properties and transport coefficients of materials and composites (heat conductivity, heat capacity, thermal elongation),

- experimental determination of thermal and fluidic parameters such as heat transfer or pressure loss coefficients.

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM