PLASMA AND LASER PROCESSES: THE ENVIRONMENTALLY FRIENDLY WAY OF SURFACE TREATMENT | Resource- and environmentally friendly processes are more in demand than ever. The functionalization of components using completely dry techniques based on the plasma or laser processing enables to slash the use of wet chemicals such as solvents, primers and rinsing media. This significantly improves the CO2 footprint of manufacturing processes and products. Fraunhofer IFAM is currently researching versatile applications of plasma and laser technologies for the pretreatment and functionalization of a wide range of technical surfaces such as metals, polymers, and glass for various industrial branches.

more infoTechnologies

-

-

EFFICIENT PLASMA COATING WITH CUSTOMIZED NOZZLES | Inline Coating with Atmospheric Pressure Plasmas has established itself as a sustainable solution in industrial manufacturing. This technology offers, for example, environmentally friendly corrosion protection and enables secure adhesion of adhesives and paints – all without the use of harmful primers. Each industrial application scenario presents individual challenges: from coating width and accessibility of complex, three-dimensional components to the treatment of temperature-sensitive materials. At Fraunhofer IFAM, customized nozzle heads are developed to flexibly address these varying requirements.

more info -

Plasma coatings: Chemical-free thin films for new surface and product properties

PLASMA COATINGS: CHEMICAL-FREE THIN FILMS FOR NEW SURFACE AND PRODUCT PROPERTIES | The demand for special functional coatings for products and semi-finished products is very high in many industrial sectors - from automotive production and plastics processing to medical technology or biotechnology. Fraunhofer IFAM is researching and developing plasma-assisted coating processes which decisively improve the range of properties of these (semi-finished) products almost independently of the material used. And without the use of chemicals! This makes these processes particularly interesting at present, because it helps companies to comply with regulations such as the REACH regulation or the HSE guidelines.

more info -

Storage samples on the Brocken during the winter months.

ENVIRONMENTAL SIMULATION FOR TESTING AND INSPECTION OF ANTI-ICE COATINGS | For the characterization of surfaces, laboratory tests under reproducible icing conditions are necessary to investigate ice formation and ice adhesion strength. This provides material developers with initial information on the performance of the surfaces. Fraunhofer IFAM determines the potential of newly developed icephobic coatings in application-specific laboratory tests.

more info -

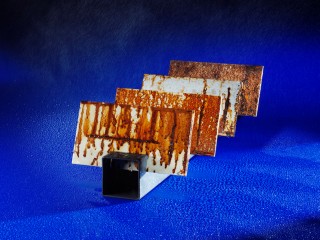

Coated steel test specimen after corrosion test.

In the corrosion testing laboratory at Fraunhofer IFAM, various test methods are available for you - for aviation, as well as for automotive and maritime technologies, and for all other applications in which corrosion protection is important. Thus, you benefit not only from the expertise of our personnel in the field of corrosion protection, but also from the diversity of our capabilities.

more info -

In today’s world, where resource conservation and sustainability are increasingly important, powder technology plays a crucial role in recycling and the circular economy. Whether metallic residues, powder waste from additive manufacturing, filter dusts, or even complex hybrid materials: what was often considered hard-to-recycle waste can be transformed at Fraunhofer IFAM into new, value-added materials and components using powder technology processes. The key advantage: powder technology enables the direct use of recycled materials – even when they are not spherical, fine powders.

more info -

Prototype kinematics of a serial industrial robot with hybrid drives at Fraunhofer IFAM in Stade.

Fraunhofer IFAM has now developed a novel solution for the dynamic improvement of the kinematics: the hybrid drive for industrial robots.

more info -

FUNCTIONALIZABLE METAL SURFACES THROUGH PLASMA ELECTROLYTIC OXIDATION (PEO) | Plasma electrolytic oxidation (PEO), also known as micro arc oxidation (MAO), is a wet chemical process that enables the production of highly functionalizable oxide layers on metals whose oxides do not have electrical conductivity, such as aluminum, magnesium, or titanium. These coatings are hard, wear-resistant, heat-resistant, and porous, making them ideal for use in aerospace, medical technology, and other high-performance industries.

more info -

Die-cast stator housing with cast-in aluminum tube as cooling structure.

Fraunhofer IFAM has been working on electromobility and the casting of electric drive components since 2008. The focus is on the development and testing of new casting concepts and design methods for electric motor castings. The field of expertise has been expanded to include the analysis and evaluation of castings for the body construction of electric vehicles, with a particular focus on giga-casting.

more info -

Reading of the QR code integrated in the casting by means of ultrasound.

RELIABLE IDENTIFICATION OF CAST COMPONENTS | The reliable identification of castings is an attractive goal in many respects. For example, it permits the unambiguous assignment of production parameters to a specific component and thus enables quality documentation, as is increasingly required not only in the aerospace industry. In addition, it forms the basis for process control based on the individual component, as is being pursued in the context of Industry 4.0 approaches.

more info

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM