Thermal Management

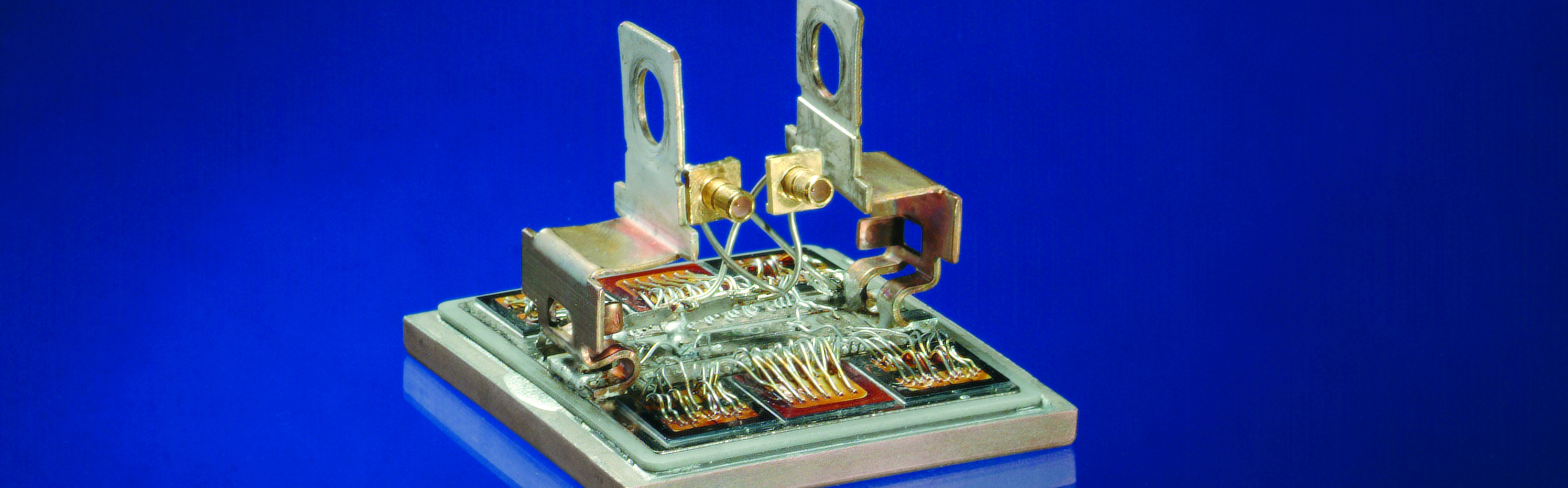

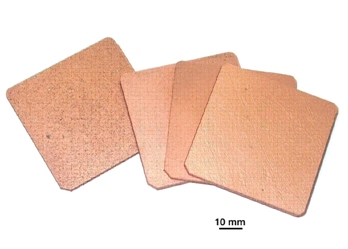

Passive heat sinks – Prototypes of a Cu composite

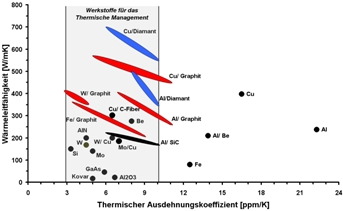

Property profile of different composites for passive heat sinks

Goal

Thermal management is an important issue in electronic packaging. Heat sinks are essential for preventing thermal damage to heat-sensitive components. Mismatch of the coefficient of thermal expansion between various metals can lead to stresses degrading lifetime and reliability. Therefore, composites with highest thermal conductivity and tailored thermal expansion behaviour for passive heat sinks have been developed. Metal-PCM (phase change material) composites can serve as latent heat accumulators or for temperature stabilisation additionally.

Materials

- Composites with different metallic matrices (e.g. Cu, Al, W) and reinforcement components (e.g. SiC, graphite, diamond, carbon fibres)

- Volume fraction of the reinforcement component can be tailored (up to max. 80 Vol.-%)

- Metal-PCM composites (e.g. Cu-, Al-matrix combined with paraffin or salts)

Applications

- Passive heat sinks in power-, micro- and optoelectronics

- Metal-PCM composites as latent heat accumulators, cooling or temperature stabilisation

Services

- Material development for specified component requirements

- Characterisation of material properties (e.g. thermal expansion, thermal conductivity)

- Manufacturing of prototypes

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM