One approach for the energy harvesting from waste-heat is the use of thermoelectric materials. They can directly convert heat from different sources (for example geothermal, solar heat or waste heat) into electricity. The state of the art for the conversion efficiency of the so-called thermoelectric energy-recovery lies around seven percent. Different classes of materials (Oxides, Half-Heusler, Clathrates, Silicides, Antimonides, Tellurides, etc.) are currently investigated worldwide in order

to increase the thermoelectric performance. However, the high thermoelectric efficiency is not the unique criterion for applications at large scale and the requirements are very complex. For example, the thermoelectric materials should be constituted of low-price and non-toxic elements with large natural availability.

Furthermore, the electric contacts should be mechanically as well as thermally and chemically stable in the complete application temperature range. In addition, the oxidation plays an important role. Protective coatings or encapsulation of the thermoelectric generator are necessary to prevent corrosion during the operation at high temperature.

The final thermoelectric device should also possess good mechanical properties since it might be exposed to temperature oscillations that damage the mechanical stability.

Materials for Energy Transformation

Thermoelectric Materials

The research activities at Fraunhofer IFAM Dresden involve aspects of applied as well as of basic research. In the field of basic research, the effect of nanostructuring on the thermoelectric properties of bulk-nanostructured materials is investigated. The starting nano-powders are produced by using Top-Down (Bi2Te3 based alloys) and Bottom-Up (Ba8Ga16Ge30-Clathrate) approaches. In both cases, the compaction into a bulk-nano-structured material with low thermal conductivity is achieved by Spark Plasma Sintering.

In comparison to the macro-crystalline material, a significant decrease of the thermal conductivity in the nano-structured material can be reached (20 % for the Clathrate and 60 % for Bi2Te3). The influence of the nanostructuring on the Seebeck effect is also currently under investigation.

Concerning the applied research at the Fraunhofer IFAM, the activities focus, amongst others, on the up-scaling of the materials production by using powder metallurgical processes and on the search for low-price thermoelectric materials.

Magnesium- and Manganese-silicides are constituted of inexpensive and low-toxicity elements. They show moderate efficiency (~ 5 %) in a temperature range from 300 °C to 650 °C and the efficiency can still be improved by tailoring the properties via doping.

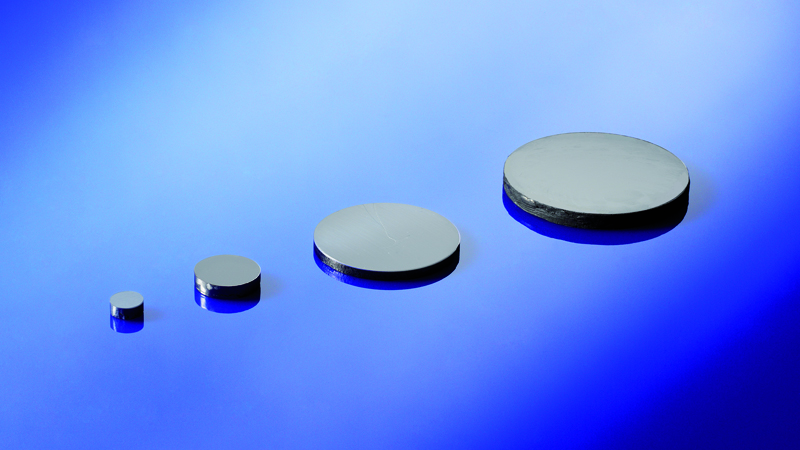

The production of Magnesium- and Manganese-silicides in a large scale is a very challenging task due to their brittle nature. Through powder metallurgical methods it is possible to reproducibly prepare high-density samples (> 95 % of the theoretical density) with diameters of 4.5 cm and 6 cm and a grain size of around 5 µm.

The thermoelectric properties of these large Magnesium- and Manganese-silicide samples are in agreement with the best values in laboratory-scale specimens reported in the literature.

Module Construction

In order to create a complete production chain (from materials development to module production), the technological processes required for the electrical contacting of silicide materials and their further assembling into thermoelectric modules are under investigation. The electric pre-contacting of silicides (diffusion barriers) is achieved by using Spark Plasma Sintering in order to establish a technology for the processing of thermoelectric materials which can be transferred to an industrial scale.

A cutting process with adjusted parameters was developed at Fraunhofer IFAM for the precise dicing of the brittle pre-contacted silicides into thermoelectric legs. Furthermore, the technology and a mounting device were developed for the simultaneous brazing of the Mg- and Mn-silicide legs and final assembling of the modules.

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM